PAUT上悬式刮刀下部卸料自动离心机

PAUT Top Suspending Scraper Bottom Discharging Automatic Centrifuge

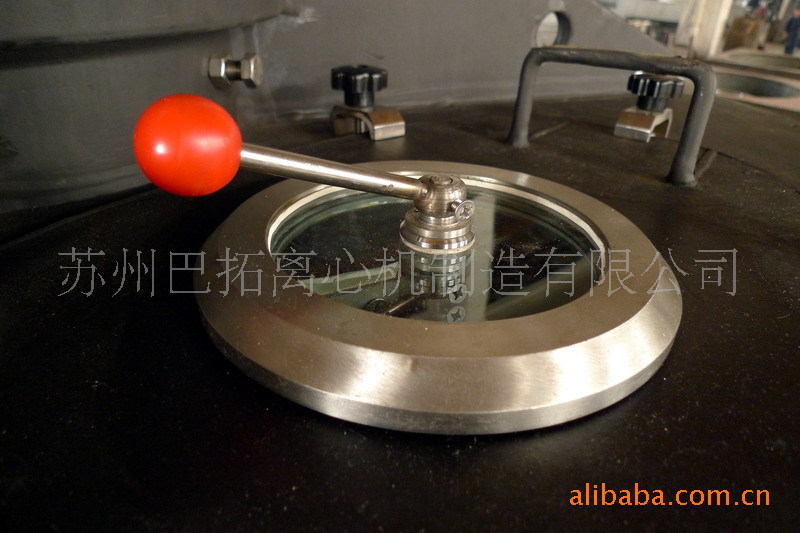

■实物拍摄图片(衬胶型)

■主要特点Features

1、平板式结构及液态阻尼减振技术:运用平板式结构,运行更平稳,操作更方便;液态阻尼减振技术的运用,使得离心机隔振和减振性能更优越;无基础安装形式,便于机器的安装和检修。

2、机壳与机座采用了平板钢性连接的全承载机壳结构,使结构更加简单,整机更加紧凑。

3、轴承支承长度大,承载性能更好;轴承座为独立式,设有上下注油通道,操作、维护方便。

4、电机与主轴直联,无传动带,彻底避免了磨擦粉尘对环境的污染。

5、下轴承端盖密封采用双重密封,可确保密封效果,主轴采用防腐新技术,能保护主轴免受腐蚀。

6、配置气体辅助刮刀和气体反冲装置,可有效消除残余滤饼层,以利滤布再生,提高过滤效果。

7、在线清洗与氮气防爆装置的应用,可实现在线清洗要求,以及实现在防爆场合的应用。

8、自动化人机界面控制:与LGZ机型一样,自动化和安全保护等装置的配置,使得机器的自动化控制程度和安全性能得到了提高。

9、动作元件驱动形式:有液压和气动两种方式供客户选用,以适应不同场合的要求。

1、Flat-type structure and the liquid damping technology: the use of flat-plate structure, operation is more stable, the operation is more convenient; liquid damping the use of technology, enabling superior performance centrifuge vibration isolation and damping; no basis for installation of forms, easy to install and repair the machine.

2、Chassis to base steel plate used to connect the entire load of chassis structure, so that structure is more simple, more compact machine.

3、The bearings supporting the length of large, bearing better performance; bearing seat as an independent type, with upper and lower oiling passage, operation and easy maintenance.

4、Motor and spindle Straight Alliance, the non-transmission belt, completely avoiding the friction dust pollution of the environment.

5、The next bearing cover seal double seal ensures sealing effect, spindle with anti-corrosion of new technologies, to protect against corrosion spindle.

6、Configuration, gas-assisted scraper and gas recoil devices, which can effectively eliminate the residual cake layer, filter cloth in order to facilitate regeneration, to improve the filtering effect.

7、On-line cleaning and the application of nitrogen explosion-proof devices can be realized-line cleaning requirements, and achieve the application of explosion-proof occasions.

8、Automatic man-machine interface control: the same as LGZ models, automation and security devices such as configuration, making the machine automation and safety performance has been improved.

9、Component-driven forms of action: There are two kinds of hydraulic and pneumatic means for customers to choose from, to suit the requirements of different occasions.

■ 标准配置Standard Manufacturing Form

1、结构:外壳配置进料管、洗涤管、观察镜、排气口、检修孔、照明孔;密闭结构。转鼓及外壳、翻盖等部件为不锈钢材料(SUS304)制造。机座等为铸造件,表面包衬不锈钢。转鼓、外壳内外表面、机器外露件表面均抛光处理。

2、所有紧固件为不锈钢件。

3、采用PLC控制。

4、传动与制动:普通电机(或防爆电机)+变频器+能耗制动。

5、气动动作系统。

6、PAUT采用平板式结构,液态阻尼减振器。

1、Structure: Shell to configure the feed pipe, wash pipe, mirrors, exhaust ports, manholes, lighting hole; airtight structure. Drum and the shell, flip and other components of stainless steel (SUS304) manufacturing. Stand such as cast parts, coated stainless steel lining. The drum shell, inside and outside surfaces, the machine parts exposed surfaces polished.

2、All fasteners for stainless steel.

3、Using PLC control.

4、Transmission and brake: Normal motor (or explosion-proof motor) + inverter + power consumption brake.

5、Pneumatic Action System.

6、PAUT using flat-plate structure, liquid damping shock absorber.

■ 选装配置Device For Choice

1、在线清洗系统。

2、氮气保护系统。

3、机电式料层控制

4、触摸屏控制。

5、液压动作系统。

6、气体辅助刮刀。

7、按用户所分离物料的防腐要求采用相应的材料(SUS304、316、316L、321等)或钛材(TA),或表面衬PE、halar等。

8、过振动保护装置。

9、现场防爆按钮。

10、传动与制动:防爆电机+变频器+能耗制动。

1、On-line Cleaning System.

2、Nitrogen protection system.

3、Electromechanical material layer control

4、Touch screen control.

5、Hydraulic motion system.

6、Gas assisted scraper.

7、Separation of materials according to user requirements using the corresponding anti-corrosion materials (SUS304, 316, 316L, 321, etc.) or titanium (TA), or surface lining PE, halar so.

8、Over vibration protection devices.

9、Explosion-proof button on the site.

10、Transmission and brake: explosion-proof motor + inverter + power consumption brake.

■技术参数Technical Parameters

项目 | 型号 | |||

PAUT1250NA | PAUT1250NB | PAUT1320N | PAUT1600N | |

转鼓直径mm | 1250 | 1250 | 1320 | 1600 |

转鼓容积L | 281 | 450 | 490 | 880 |

最大装料限量kg | 380 | 610 | 600 | 1180 |

转鼓转速r/min | 970 | 970 | 900 | 750 |

分离因数 | 658 | 658 | 598 | 504 |

电机功率kw | 22 | 30 | 30 | 45 |

外形尺寸(长宽高)mm | 2000*2000*2200 | 2000*2000*2600 | 2000*2000*2600 | 2700*2350*2800 |

机器重量kg | 4200 | 4800 | 5000 | 10000 |