肯倍焊接机器人系统自动化焊接电源脉冲焊机KempArc Pulse 450

KempArc焊机是专为MIG/MAG自动化焊接而设计的。450A脉冲机型可使用一元化或脉冲焊接工艺。该系列焊机可进行逻辑工艺调节,以保证在繁忙作业时完成快速设置。

Wise焊接专家程序自动化产品提供额外的、与实际焊接相匹配的选择和解决方案,可确保满足您现在和将来的焊接要求。

产品概要

•一元化或脉冲MIG / MAG焊接

•数字或模拟接口机型

•小巧轻盈的送丝机构

•兼容Wise焊接专家程序

•KempArc Browser机器人接口

KempArc 的主要特点

KempArc 自动化焊机系列可根据特定焊接环境设置标准或定制软件程序包,例如KempArc Pulse焊机系列可提供Work Pack全能软件包,包括碳钢焊接、铝合金焊接、不锈钢焊接的软件,或完全符合现场具体需要的Project Pack专家软件库。两种软件包都可以随时进行升级。

选择集成了不同的机器人控制系统的数字机型或模拟机型。全数字化控制确保了精确引弧和焊接质量所需的高速通讯速度。存储通道可作为独立参数存储系统。

KempArc Browser机器人接口可用来轻松控制KempArc机器人焊机的焊接参数。通过KempArc Browser浏览器打开控制面板即可进行控制,用户还可以通过内联网或笔记本电脑与它连接,从而对KempArc系统进行维修和管理。

KempArc 的选配件

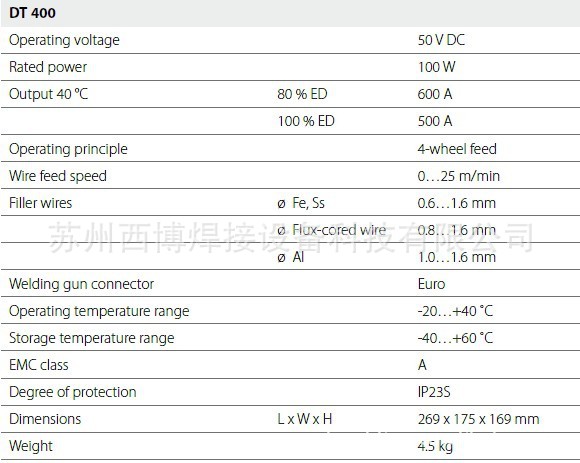

DT400送丝装置,安装于机器人臂上,或作为机械化焊接系统的集成送丝解决方案。 DT400结构紧凑,重量轻,配备了4x4的送丝机构。

KempCool 10 冷却装置,其冷却功率为 1 千瓦,可确保焊枪在焊接作业时保持低温。

DT400 送丝装置KF 62控制板,为KempArc脉冲电源提供遥控焊接控制。

Why buy

• Synergic or pulsed MIG/MAG welding

• Digital or analogue models

• Compact, lightweight wire drive mechanism

• Wise welding solutions compatible

• KempArc browser robot interface

Application

• Robotic welding

• Mechanised welding

• Automated systems

Key features

KempArc is specifically designed for MIG/MAG welding automation.

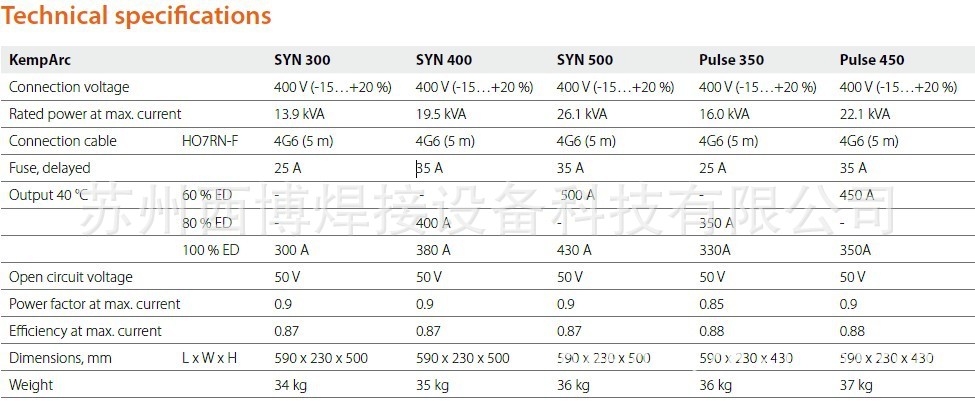

Synergic or pulsed welding process variants are available in either 300, 400 or 500 amp synergic models, or 350 or 450 amp pulsed models. Each range offers logical process adjustment, ensuring quick setup for busy industry.

KempArc automation range allows standard or tailored welding packages to suit your specific welding environment. For example KempArc Pulse range offers Work Pack, including welding software selections for steel, aluminium, and stainless steel filler wires, or Project Pack where you match your specific local welding needs perfectly. Either version can be upgraded at anytime.

Choose either digital or analogue models for integration with different robotic control systems. Digital process management ensures fast communication speeds for precise ignition and welding quality. Memory channels are available as standard for systems that demand independent parameter storage.

Options

Wise™ process functions for automation applications offer additional choice and solutions that match welding in the real world, so you can be sure to cover your welding requirements now and far into the future.

KempArc Browser robot interface is an easy way to control the welding parameters of KempArc robotic welding equipment. Just take your teach pendant device and open the control panel with the KempArc Browser. You can also connect to it through intranet or with a laptop for easy maintenance and service of your KempArc system.

DT400 wire feed unit mounts to the back of the robot arm or as a convenient integrated wire feed solution for any mechanised welding system. DT400 is compact and light in weight, incorporating a 4x4 drive mechanism and full metal feed rolls.

KF 62 control pendant offers remote welding control for KempArc Pulse power source.