美国派克防爆伺服电机EX310 EX420 X430

西安板升机电科技有限公司

东关正街66号D座2108室

产品属性

图文详情

品牌推荐

品牌/型号

美国派克/EX310

额定电压

230/400(V)V

功率

1(KW)kw

型号

EX310

品牌

美国派克

产品认证

CE EX ATEX

加工定制

是

西安板升机电科技有限公司作为上海板升自动化科技有限公司在西安的分公司,真诚为您服务。Servomotors for explosive atmospheres

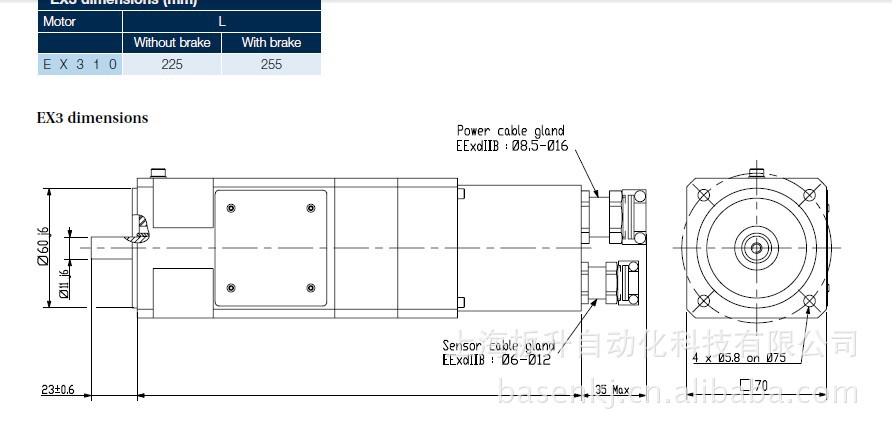

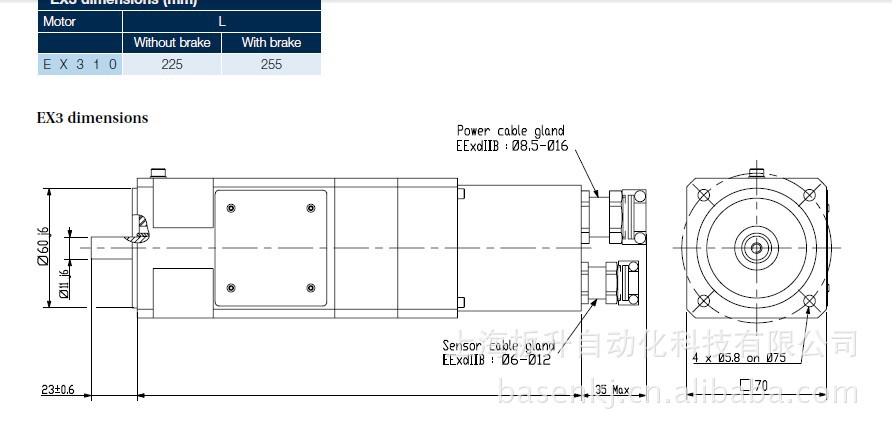

EX series

1,75 to 35 Nm

Description

EX series is a range of permanent magnets servomotors

designed for use in explosive atmospheres. Featuring

robust explosion-proof housings, EX motors are capable

of bearing internal explosions with no risks of propagation

to the neighbouring environment. Two versions are

available, conforming with north american or european

safety standards. EX servomotors are characterized by

excellent motion quality, great acceleration / deceleration

capabilities, and high torque output over a wide speed

range. Various winding variants and numerous options are

available to offer maximum flexibility.

Advantages

Servomotors with explosion proof housings

CE or UL versions available

High dynamic performances

Compactness and robustness

No maintenance

Applications

• Printing machinery

• Paint spray equipments

• Plastics machinery

• Chemical, petro-chemical and pharmaceutical industries

• Waste processing plants…

General technical characteristics

Motor type Permanent magnets synchronous motors

Number of poles 10

Torque range 1,75 to 35 Nm

Speed range 2000 to 8000 rpm

Mounting - Flange with smooth holes

Mechanical

interface

- Solid smooth shaft (standard)

- Solid shaft with key (option)

Feedback sensors

- 2 poles resolver (standard)

- Absolute EnDat encoder (option)

- Absolute Hiperface encoder (option)

Thermal

protection

- Thermoswitches and thermofuses integrated

to the winding

Other options - Parking brake

Voltage supply 230 / 400 VAC 230/ 480 VAC

Conformance - ATEX 94/9/EC

Directive

- EN60079-0,

EN60079-1

EN61241-0 and

EN61241-1

standards

- UL 674 standard :

Electric Motors and

Generators for use in

Division 1 Hazardous

(Classified) Locations

Classification - II 2G Ex d IIB T4

IP64 (Gaz)

- II 2GD Ex d IIB

T4 IP65 Ex tD A21

IP65 T135°C

(Gas and dust)

- Class 1, Division 1,

Group C & D

Ingress protection

level

- IP64 (standard)

- IP65 (option)

- IP65

Connections - cable glands - Tapped holes

Marking

1

Rated

Speed

NMAX

(rpm)

Stall

Torque

M0

(Nm)

Stall

Current

I0

(ARMS)

Rated

Torque

MN

(Nm)

Rated

Current

IN

(ARMS)

Peak

Torque

MMAX

(Nm)

Peak

Current

IMAX

(ARMS)

Max.

Speed with

Compax3

NMAX

(rpm)

Moment of

Inertia

J

(kgm²x10-5)

Reference

230 VAC power supply

2300

4000

2300

4000

3200

4000

2500

3000

2200

3600

2200

2500

1.75

1.75

3.5

3.5

4.8

4.8

7

10.4

14

14

24.5

35

1.24

2.16

2.46

4.26

4.57

5.8

5.51

10

9.28

14.85

16.04

27.3

1.66

1.54

3.18

2.67

3.74

3.26

5.49

7.24

11.16

7.53

14.18

8.5

1.19

1.96

2.26

3.33

3.63

4.05

4.47

7.32

7.45

8.3

9.54

7.28

6.6

6.6

13.4

13.4

18.8

18.8

26.7

40

50

50

92

137

5.64

9.85

11.3

19.6

21

26.6

24.8

42.2

41.8

66.9

72.7

133

1960

3630

2030

3700

2930

3790

2310

2860

2050

3430

2120

2500

7.9

7.9

29

29

42.6

42.6

98

147

320

320

620

920

E X 3 1 0 E

E X 3 1 0 E

E X 4 2 0 E

E X 4 2 0 E

E X 4 3 0 E

E X 4 3 0 E

E X 6 2 0 E

E X 6 3 0 E

E X 8 2 0 E

E X 8 2 0 E

E X 8 4 0 E

E X 8 6 0 E

■

■

■

■

■

■

■

■

■

■

■

■

P R 1

K R 1

P R 1

J R 1

J R 1

F R 1

O R 1

I R 1

R R 1

L R 1

J R 1

D R 1

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

400VAC power supply

4000

2000

4000

3000

4000

4300

2900

4000

2200

3600

2100

3300

2500

1.75

3.5

3.5

4.8

4.8

7

10.4

10.4

14

14

24.5

24.5

35

1.24

1.24

2.46

2.46

3.3

5.22

5.54

7.5

5.4

9.3

8.55

14.3

15.4

1.54

3.22

2.68

3.85

3.26

3.13

7.42

5.2

11.16

7.53

15

2.85

8.5

1.12

1.15

1.93

2

2.31

2.75

4.12

4.08

4.36

5.19

5.37

2.07

4.1

6.6

13.4

13.4

18.8

18.8

26.7

40

40

50

50

92

92

137

5.64

5.68

11.3

11.3

15.1

24.8

23.2

31.4

24.3

41.8

38.8

64.7

75

3600

1740

3720

2740

3740

4240

2750

3820

2080

3600

1950

3300

2500

7.9

29

29

42.6

42.6

98

147

147

320

320

620

620

920

E X 3 1 0 E

E X 4 2 0 E

E X 4 2 0 E

E X 4 3 0 E

E X 4 3 0 E

E X 6 2 0 E

E X 6 3 0 E

E X 6 3 0 E

E X 8 2 0 E

E X 8 2 0 E

E X 8 4 0 E

E X 8 4 0 E

E X 8 6 0 E

■

■

■

■

■

■

■

■

■

■

■

■

■

P R 1

V R 1

P R 1

P R 1

L R 1

O R 1

Y R 1

N R 1

W R 1

R R 1

Q R 1

K R 1

J R 1

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

CE servomotors

EX series

1,75 to 35 Nm

1

EX series

1,75 to 35 Nm

Description

EX series is a range of permanent magnets servomotors

designed for use in explosive atmospheres. Featuring

robust explosion-proof housings, EX motors are capable

of bearing internal explosions with no risks of propagation

to the neighbouring environment. Two versions are

available, conforming with north american or european

safety standards. EX servomotors are characterized by

excellent motion quality, great acceleration / deceleration

capabilities, and high torque output over a wide speed

range. Various winding variants and numerous options are

available to offer maximum flexibility.

Advantages

Servomotors with explosion proof housings

CE or UL versions available

High dynamic performances

Compactness and robustness

No maintenance

Applications

• Printing machinery

• Paint spray equipments

• Plastics machinery

• Chemical, petro-chemical and pharmaceutical industries

• Waste processing plants…

General technical characteristics

Motor type Permanent magnets synchronous motors

Number of poles 10

Torque range 1,75 to 35 Nm

Speed range 2000 to 8000 rpm

Mounting - Flange with smooth holes

Mechanical

interface

- Solid smooth shaft (standard)

- Solid shaft with key (option)

Feedback sensors

- 2 poles resolver (standard)

- Absolute EnDat encoder (option)

- Absolute Hiperface encoder (option)

Thermal

protection

- Thermoswitches and thermofuses integrated

to the winding

Other options - Parking brake

Voltage supply 230 / 400 VAC 230/ 480 VAC

Conformance - ATEX 94/9/EC

Directive

- EN60079-0,

EN60079-1

EN61241-0 and

EN61241-1

standards

- UL 674 standard :

Electric Motors and

Generators for use in

Division 1 Hazardous

(Classified) Locations

Classification - II 2G Ex d IIB T4

IP64 (Gaz)

- II 2GD Ex d IIB

T4 IP65 Ex tD A21

IP65 T135°C

(Gas and dust)

- Class 1, Division 1,

Group C & D

Ingress protection

level

- IP64 (standard)

- IP65 (option)

- IP65

Connections - cable glands - Tapped holes

Marking

1

Rated

Speed

NMAX

(rpm)

Stall

Torque

M0

(Nm)

Stall

Current

I0

(ARMS)

Rated

Torque

MN

(Nm)

Rated

Current

IN

(ARMS)

Peak

Torque

MMAX

(Nm)

Peak

Current

IMAX

(ARMS)

Max.

Speed with

Compax3

NMAX

(rpm)

Moment of

Inertia

J

(kgm²x10-5)

Reference

230 VAC power supply

2300

4000

2300

4000

3200

4000

2500

3000

2200

3600

2200

2500

1.75

1.75

3.5

3.5

4.8

4.8

7

10.4

14

14

24.5

35

1.24

2.16

2.46

4.26

4.57

5.8

5.51

10

9.28

14.85

16.04

27.3

1.66

1.54

3.18

2.67

3.74

3.26

5.49

7.24

11.16

7.53

14.18

8.5

1.19

1.96

2.26

3.33

3.63

4.05

4.47

7.32

7.45

8.3

9.54

7.28

6.6

6.6

13.4

13.4

18.8

18.8

26.7

40

50

50

92

137

5.64

9.85

11.3

19.6

21

26.6

24.8

42.2

41.8

66.9

72.7

133

1960

3630

2030

3700

2930

3790

2310

2860

2050

3430

2120

2500

7.9

7.9

29

29

42.6

42.6

98

147

320

320

620

920

E X 3 1 0 E

E X 3 1 0 E

E X 4 2 0 E

E X 4 2 0 E

E X 4 3 0 E

E X 4 3 0 E

E X 6 2 0 E

E X 6 3 0 E

E X 8 2 0 E

E X 8 2 0 E

E X 8 4 0 E

E X 8 6 0 E

■

■

■

■

■

■

■

■

■

■

■

■

P R 1

K R 1

P R 1

J R 1

J R 1

F R 1

O R 1

I R 1

R R 1

L R 1

J R 1

D R 1

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

400VAC power supply

4000

2000

4000

3000

4000

4300

2900

4000

2200

3600

2100

3300

2500

1.75

3.5

3.5

4.8

4.8

7

10.4

10.4

14

14

24.5

24.5

35

1.24

1.24

2.46

2.46

3.3

5.22

5.54

7.5

5.4

9.3

8.55

14.3

15.4

1.54

3.22

2.68

3.85

3.26

3.13

7.42

5.2

11.16

7.53

15

2.85

8.5

1.12

1.15

1.93

2

2.31

2.75

4.12

4.08

4.36

5.19

5.37

2.07

4.1

6.6

13.4

13.4

18.8

18.8

26.7

40

40

50

50

92

92

137

5.64

5.68

11.3

11.3

15.1

24.8

23.2

31.4

24.3

41.8

38.8

64.7

75

3600

1740

3720

2740

3740

4240

2750

3820

2080

3600

1950

3300

2500

7.9

29

29

42.6

42.6

98

147

147

320

320

620

620

920

E X 3 1 0 E

E X 4 2 0 E

E X 4 2 0 E

E X 4 3 0 E

E X 4 3 0 E

E X 6 2 0 E

E X 6 3 0 E

E X 6 3 0 E

E X 8 2 0 E

E X 8 2 0 E

E X 8 4 0 E

E X 8 4 0 E

E X 8 6 0 E

■

■

■

■

■

■

■

■

■

■

■

■

■

P R 1

V R 1

P R 1

P R 1

L R 1

O R 1

Y R 1

N R 1

W R 1

R R 1

Q R 1

K R 1

J R 1

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

CE servomotors

EX series

1,75 to 35 Nm

1