GW型管道式无堵塞排污泵 不锈钢潜水排污泵 碳钢潜水排污泵&a

、

| |

| GW型管道式无堵塞排污泵 | GW型管道式无堵塞排污泵,(简称:GW排污泵),具有以下特点: 1. 泵为立式单吸单级离心排污泵,进出口中心线在同一水平线上,进出口法兰相同,故安装拆卸十分方便,占地面积小,可像阀门一样安装在管路的任何位置上。

2. 泵与电机直联同轴,属机电一体化产品,结构紧凑,性能稳定。

3. 采用大流道抗堵塞水力部件设计,大大提高污物通过能力,能有效地通过泵口径的5倍纤维物质和直径为泵口径约50%d 固体颗粒。

4. 设计合理,配套电机合理,效率高,节能效果显著。

5. 机械密封采用硬质耐磨碳化钨,具有耐用、耐磨等特点,可以使泵安全连续运行8000小时以上。

6. 水力性能先进,整机效率高,运转噪音低。

7. 在电机风叶端加上防护罩,整机可置于室外工作,无需机房,可节省大量基建费用。

8. 在使用扬程范围内使用,保证电机无过载。

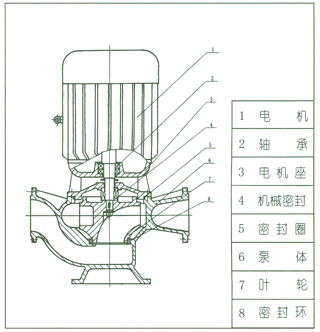

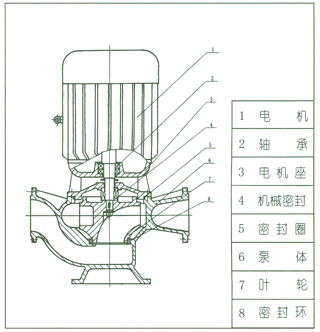

结构说明 GW型系列无堵塞单级管道排污泵系进出口在同一水平线上,且规格相同,立式结构,占地面积小,电机与泵同轴,设有安装底盘,便于安装稳固,叶轮采用单(双)流道,具有良好的通过性能。

性能参数表 | 序号 | 型号 | 口径 | 流量 | 扬程 | 转速 | 功率 | 效率 | 使用扬程范围 | | Type | mm | m3h | m | r/min | KW | | | 1 | 25GW8-22-1.1 | 25 | 8 | 22 | 2825 | 1.1 | 38.5 | 10-22 | | 2 | 32GW12-15-1.1 | 32 | 12 | 15 | 2825 | 1.1 | 40 | 8-15 | | 3 | 40GW15-15-1.5 | 40 | 15 | 15 | 2840 | 1.5 | 45.1 | 6-15 | | 4 | 40GW15-30-2.2 | 40 | 15 | 30 | 2840 | 2.2 | 48 | 15-30 | | 5 | 50GW20-7-0.75 | 50 | 20 | 7 | 1390 | 0.75 | 54 | 3-7 | | 6 | 50GW10-10-0.75 | 50 | 10 | 10 | 1390 | 0.75 | 56 | 4-10 | | 7 | 50GW20-15-1.5 | 50 | 20 | 15 | 2840 | 1.5 | 55 | 6-15 | | 8 | 50GW15-25-2.2 | 50 | 15 | 25 | 2840 | 2.2 | 56 | 10-25 | | 9 | 50GW18-30-3 | 50 | 18 | 30 | 2880 | 3 | 58 | 15-30 | | 10 | 50GW25-32-5.5 | 50 | 25 | 32 | 2900 | 5.5 | 53 | 17-32 | | 11 | 50GW20-40-7.5 | 50 | 20 | 40 | 2900 | 7.5 | 55 | 20-40 | | 12 | 65GW25-15-2.2 | 65 | 25 | 15 | 2840 | 2.2 | 52 | 6-15 | | 13 | 65GW37-13-3 | 65 | 37 | 13 | 2880 | 3 | 55 | 6-13 | | 14 | 65GW25-30-4 | 65 | 25 | 30 | 2890 | 4 | 58 | 15-30 | | 15 | 65GW30-40-7.5 | 65 | 30 | 40 | 2900 | 7.5 | 56 | 20-40 | | 16 | 65GW35-50-11 | 65 | 35 | 50 | 2930 | 11 | 60 | 35-50 | | 17 | 65GW35-60-15 | 65 | 35 | 60 | 2930 | 15 | 63 | 40-60 | | 18 | 80GW40-7-2.2 | 80 | 40 | 7 | 1420 | 2.2 | 52 | 3-7 | | 19 | 80GW43-13-3 | 80 | 43 | 13 | 2880 | 3 | 50 | 5-13 | | 20 | 80GW40-15-4 | 80 | 40 | 15 | 2890 | 4 | 57 | 6-15 | | 21 | 80GW65-25-7.5 | 80 | 65 | 25 | 2900 | 7.5 | 56 | 12-25 | | 22 | 100GW80-10-4 | 100 | 80 | 10 | 1440 | 4 | 62 | 4-10 | | 23 | 100GW110-10-5.5 | 100 | 110 | 10 | 1440 | 5.5 | 66 | 5-10 | | 24 | 100GW100-15-7.5 | 100 | 100 | 15 | 1440 | 7.5 | 67 | 8-15 | | 25 | 100GW85-20-7.5 | 100 | 85 | 20 | 1440 | 7.5 | 68 | 10-20 | | 26 | 100GW100-25-11 | 100 | 100 | 25 | 1460 | 11 | 65 | 10-25 | | 27 | 100GW100-30-15 | 100 | 100 | 30 | 1460 | 15 | 66 | 12-30 | | 28 | 100GW100-35-18.5 | 100 | 100 | 35 | 1470 | 18.5 | 65 | 15-35 | | 29 | 125GW130-15-11 | 125 | 130 | 15 | 1460 | 11 | 62 | 7-15 | | 30 | 125GW130-20-15 | 125 | 130 | 20 | 1460 | 15 | 63 | 10-20 | | 31 | 150GW145-9-7.5 | 150 | 145 | 9 | 1440 | 7.5 | 63 | 4-9 | | 32 | 150GW180-15-15 | 150 | 180 | 15 | 1460 | 15 | 65 | 5-15 | | 33 | 150GW180-20-18.5 | 150 | 180 | 20 | 1470 | 18.5 | 75 | 8-20 | | 34 | 150GW180-25-22 | 150 | 180 | 25 | 1470 | 22 | 76 | 12-25 | | 35 | 150GW130-30-22 | 150 | 130 | 30 | 1470 | 22 | 75 | 15-30 | | 36 | 150GW180-30-30 | 150 | 180 | 30 | 1470 | 30 | 73 | 15-30 | | 37 | 150GW200-30-34 | 150 | 200 | 30 | 1480 | 37 | 70 | 13-30 | | 38 | 200GW300-7-11 | 200 | 300 | 7 | 970 | 11 | 73 | 3-7 | | 39 | 200GW250-11-15 | 200 | 250 | 11 | 970 | 15 | 74 | 4-11 | | 40 | 200GW400-10-22 | 200 | 400 | 10 | 1470 | 22 | 76 | 5-10 | | 41 | 200GW400-13-30 | 200 | 400 | 13 | 1470 | 30 | 73 | 6-13 | | 42 | 200GW250-15-18.5 | 200 | 250 | 15 | 1470 | 18.5 | 72 | 7-15 | | 43 | 200GW300-15-22 | 200 | 300 | 15 | 1470 | 22 | 73 | 8-15 | | 44 | 200GW250-22-30 | 200 | 250 | 22 | 1470 | 30 | 71 | 12-22 | | 45 | 200GW350-25-37 | 200 | 350 | 25 | 1980 | 37 | 75 | 10-25 | | 46 | 200GW400-30-45 | 200 | 400 | 30 | 1480 | 45 | 70 | 13-30 | | 47 | 250GW600-9-30 | 250 | 600 | 9 | 980 | 30 | 74 | 3-9 | | 48 | 250GW600-12-37 | 250 | 600 | 12 | 1480 | 37 | 78 | 5-12 | | 49 | 250GW600-15-45 | 250 | 600 | 15 | 1480 | 45 | 75 | 6-15 | | 50 | 250GW600-20-55 | 250 | 600 | 20 | 1480 | 55 | 73 | 8-20 | | 51 | 250GW600-25-75 | 250 | 600 | 25 | 1480 | 75 | 73 | 12-25 | | 52 | 250GW800-12-45 | 250 | 800 | 12 | 980 | 45 | 76 | 5-12 | | 53 | 300GW500-15-45 | 300 | 500 | 15 | 980 | 45 | 70 | 7-15 | | 54 | 300GW800-15-55 | 300 | 800 | 15 | 980 | 55 | 73 | 8-15 | | 55 | 300GW600-20-55 | 300 | 600 | 20 | 980 | 55 | 75 | 10-20 | | 56 | 300GW800-20-75 | 300 | 800 | 20 | 980 | 75 | 78 | 12-20 | | 57 | 300GW950-20-90 | 300 | 950 | 20 | 980 | 90 | 80 | 11-20 | | 58 | 300GW1000-25-110 | 300 | 1000 | 25 | 980 | 110 | 82 | 12-25 | | 59 | 350GW1100-10-55 | 350 | 1100 | 10 | 980 | 55 | 84.5 | 4-10 | | 60 | 350GW1500-15-90 | 350 | 1500 | 5 | 980 | 90 | 82.5 | 6-15 | | 61 | 350GW1200-18-90 | 350 | 1200 | 18 | 980 | 90 | 83.1 | 8-18 | | 62 | 350GW1100-28-132 | 350 | 1100 | 28 | 740 | 132 | 83.2 | 15-25 | | 63 | 350GW1000-36-160 | 350 | 1000 | 36 | 740 | 160 | 78.5 | 20-36 | | 64 | 400GW1500-10-75 | 400 | 1500 | 10 | 980 | 75 | 82.1 | 3-10 | | 65 | 400GW2000-15-132 | 400 | 2000 | 15 | 740 | 132 | 85.5 | 6-15 | | 66 | 400GW1700-22-160 | 400 | 1700 | 22 | 740 | 160 | 82.1 | 10-22 | | 67 | 400GW1500-26-160 | 400 | 1500 | 26 | 740 | 160 | 83.5 | 12-26 | | 68 | 400GW1700-30-200 | 400 | 1700 | 30 | 740 | 200 | 83.5 | 15-30 | | 69 | 400GW1800-32-250 | 400 | 1800 | 32 | 740 | 250 | 82.1 | 17-32 |

|

|