97 90 80含量黑色碳化硅 量大从优 质量保障

碳化硅概术:

碳化硅(SiC)是用石英砂、石油焦(或煤焦)、木屑为原料通过电阻炉高温冶炼而成。碳化硅在大自然也存在罕见的矿物,莫桑石。 碳化硅又称碳硅石。在当代C、N、B等非氧化物高技术耐火原料中,碳化硅为应用最广泛、最经济的一种。可以称为金钢砂或耐火砂。 碳化硅是用石英砂、石油焦(或煤焦)、木屑(生产绿色碳化硅时需要加食盐)等原料在电阻炉内经高温冶炼而成。目前我国工业生产的碳化硅分为黑色碳化硅和绿色碳化硅两种,均为六方晶体,比重为3.20~3.25,显微硬度为2840~3320kg/mm2。

碳化硅有黑碳化硅和绿碳化硅两个常用的基该品种,都属α-SiC。

①黑碳化硅含SiC约95%,其韧性高于绿碳化硅,大多用于加工抗张强度低的材料,如玻璃、陶瓷、石材、耐火材料、铸铁和有色金属等。

②绿碳化硅含SiC约97%以上,自锐性好,大多用于加工硬质合金、钛合金和光学玻璃,也用于珩磨汽缸套和精磨高速钢刀具。此外还有立方碳化硅,它是以特殊工艺制取的黄绿色晶体,用以制作的磨具适于轴承的超精加工,可使表面粗糙度从Ra32~0.16微米一次加工到Ra0.04~0.02微米。

碳化硅由于化学性能稳定、导热系数高、热膨胀系数小、耐磨性能好,除作磨料用外,还有很多其他用途,例如:以特殊工艺把碳化硅粉末涂布于水轮机叶轮或汽缸体的内壁,可提高其耐磨性而延长使用寿命1~2倍;用以制成的高级耐火材料,耐热震、体积小、重量轻而强度高,节能效果好。低品级碳化硅(含SiC约85%)是极好的脱氧剂,用它可加快炼钢速度,并便于控制化学成分,提高钢的质量。此外,碳化硅还大量用于制作电热元件硅碳棒。

碳化硅的硬度很大,具有优良的导热性能,是一种半导体,高温时能抗氧化。

碳化硅指标:

磨料磨具用碳化硅国家标准 磨料磨具用碳化硅 本标准适用于制造磨具或作研磨材料等用的碳化硅。 技术条件 1 化学成份应符合下表规定: | ||||

粒度范围 | SiC 不小于 | 游离碳不多于 | Fe2O3% | |

黑碳化硅 | 12#-90# | 98.5 | 0.2 | 0.6 |

| 100#-180# | 98 | 0.3 | 0.8 |

| 220#-240# | 97 | 0.3 | 1.2 |

绿碳化硅 | 20#-90# | 99 | 0.2 | 0.2 |

| 100#-80# | 98.5 | 0.25 | 0.5 |

| 220#-240# | 97.5 | 0.25 | 0.7 |

| W63-W20 | 97 | 0.3 | 0.7 |

| W14-W10 | 95.5 | 0.3 | 0.7 |

| W7-W5 | 94 | 0.3 | 0.7 |

2.密度:46#粒度(代表号)绿碳化硅不小于3.18克/厘米3.黑碳化硅不小于3.12克/厘米. 3.粒度组成:应符合GB2477-83《磨料粒度及其组成》的规定 4.铁合金粒的允许含量:30#及以粗的各号以不通过45#筛的铁合金粒为零;36#至90#各号以下通过粒度检查时最低层筛号的铁合金粒为零;100#及以细各号以不通过粒度筛检查时混合粒下层筛的铁合金为零。 5.磁性物允许含量:12#至240#的磁性物含量不大于0.20%. | ||||

(2)作为冶金脱氧剂和耐高温材料。

碳化硅主要有四大应用领域,即: 功能陶瓷、高级耐火材料、磨料及冶金原料。目前碳化硅粗料已能大量供应, 不能算高新技术产品,而技术含量极高 的纳米级碳化硅粉体的应用短时间不可能形成规模经济。

(3)高纯度的单晶,可用于制造半导体、制造碳化硅纤维。

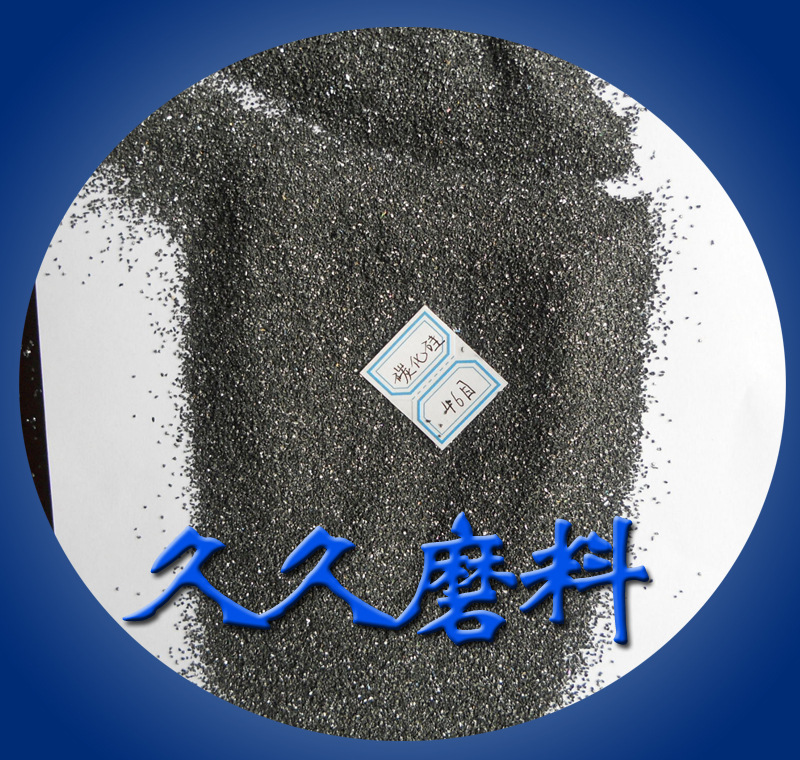

黑碳化硅称为黑碳化硅粒度砂,黑碳化硅分黑碳化硅粒度砂和黑碳化硅微粉两大类产品.

黑碳化硅粒度砂是用碳化硅自然块经过粉碎,研磨,酸碱洗,水洗,烘干,筛分等工艺,原料:石英砂(Sio2)和无烟煤或石油焦(c),在摄氏1800度以上高温条件下生成的非金属矿产品,它具有硬度高,膨胀系数小,性脆,导热性好等特点,广泛应用于磨料磨具,电子产品研磨,耐火材料,特种陶瓷,泡沫陶瓷,涂料塑料添加改性,汽车配件,军工航空,炼钢用脱氧剂等.

耐火材料用碳化硅:在生产和加工碳化硅过程中有大量碳化硅含量90%以下的碳化硅形成与产出,俗称为低硅.低含量碳化硅的主要用途为耐火材料行业,炼钢行业的脱氧剂,炮泥,浇铸料,铁沟料.我公司每年有5000吨以上的低含量碳化硅供应,该类产品含量分布为:90%,88%,85%,80%,75%,70%,65%,60%,55%,50%,45%,40%.粒度以60#以细为主。

耐火材料用碳化硅部分理化指标: JB/CQ

6001-82本标准适用于制作耐火材料使用的碳化硅砂或作耐火砂耐火泥用的碳化硅砂

一.名称及代号 耐火材料用碳化硅的名称、代号及特征见表。

名称 | 外观 | SiC ≥ | F.C ≤ | Fe2O3%≤ |

高级碳化硅耐火砂 | 黑色粗结晶 | 97 | 0.3 | 0.5 |

碳化硅耐火砂 | 黑色粗结晶和细结晶 | 90 | 2.5 | 2 |

普通碳化硅耐火砂 | 黑色细结晶 | 75 | 7 | 2 |

2.耐火材料用碳化硅砂的粒度规格为3.15mm以细。其中3.15-0.1mm者应占85%以上。 注:用户如有特殊要求,允许按照用户要求的粒度生产。

3.耐火材料用碳化硅中不得混有肉眼可见的低熔点夹杂物(如金属屑)等。

碳化硅规格:

生产执行标准为中国标准,国际标准,日本标准,欧洲标准.

我公司生产的欧洲标准的产品型号如下:

F6,F8,F10,F12,F16,F18,F20,F22,F24,F30,F36,F40,F46,F54,F60,F70,F80,

F90,F100,F120,F150,F180,F220,F240

粉状黑碳化硅产品:1.采用干法,湿法,干湿相结合的方法生产碳化硅微粉,以适用于不同产品的不同需求.产品主要用于耐火材料类产品的制造,泡沫陶瓷行业,太阳能硅板切割,水晶切割研磨,汽车发动原件制造,特种涂料行业,塑料制品改性,脱硫供电环保行业等.2.黑碳化硅微粉按中国及欧洲标准分类的型号为:中国标准:W63,W50,W40,W28,W20,W14,W10,W7,W5,W3.5,W2.5,W1.5;欧洲标准:F280,F320,F400,F500,F600,F800,F1000,F1200,F1500,F1800;同时,我公司还可以生产日本标准,及按客户需要的非标产品,特殊需要的产品,分布范围大的产品,含量不同的产品。

silicon carbide shall:

Silicon carbide (SiC) is using quartz sand and petroleum coke or coal tar, wood chips as raw material through high temperature electric resistance furnace smelting. There is also a rare mineral silicon carbide in nature, and the mo SangShi. Silicon carbide is also called the moissanite. In contemporary, N, B, C of oxide refractory raw materials in the high technology, such as silicon carbide as the most widely used, one of the most economic. Can be called corundum sand and refractory. Silicon carbide is using quartz sand and petroleum coke or coal tar, wood chips (green silicon carbide production need to add salt) raw materials such as in the Canon of high-temperature resistance furnace smelting. At present, the industrial production of silicon carbide can be pided into two, green silicon carbide black silicon carbide and are six-party crystal, specific gravity is 3.20 ~ 3.25, the microhardness of 2840 ~ 3320 kg/was.

Green silicon carbide black silicon carbide and silicon carbide two commonly used the base of the varieties, are alpha SiC. (1) black silicon carbide containing SiC by about 95%, the toughness is higher than the green silicon carbide, mostly used for processing low tensile strength of material, such as glass, ceramic, stone, refractory material, cast iron and non-ferrous metal, etc. (2) and green silicon carbide containing SiC is about more than 97%, good self-sharpening, mostly used for processing hard alloy, titanium alloy and optical glass, also for honing of cylinder jacket and fine grinding HSS cutting tools. And cubic silicon carbide, it is a special process for making yellow crystals, to make the abrasive tool is suitable for bearing the superfinishing, can make the surface roughness of machining at a time from Ra32 ~ 0.16 microns to Ra0.04 ~ 0.02 microns. Because silicon carbide chemical performance is stable, high coefficient of thermal conductivity, low thermal expansion coefficient, wear-resisting performance is good, except for abrasive, there are many other USES, such as: silicon carbide powder coated with a special process in the turbine impeller or the lining of the cylinder body, can improve the wear resistance and prolong the service life of the 1 ~ 2 times; Used to made of high-grade refractory materials, thermal shock, small volume, light weight and high strength, good energy saving effect. About 85% low grade silicon carbide (SiC) is an excellent deoxidizing agent, it can speed up steel making, and is convenient for controlling chemical composition, improve the quality of steel. In addition, silicon carbide also used to produce large amounts of electric heating element silicon carbon rod. Silicon carbide hardness is very big, it has excellent thermal conductivity, is a kind of semiconductor, resistant to oxidation at high temperature.

Silicon carbide indicators:

Abrasives used with silicon carbide silicon carbide abrasives national standards GB 2480-83, this standard applies to manufacturing silicon carbide abrasive and abrasive materials. Technical provisions 1 chemical composition shall conform to the following table:

SiC particle size range is not less than the free carbon less than Fe2O3 % less than

12 # - 90 # 98.50.20.6 black silicon carbide

100 # - 180 # 980.30.8

220 # - 240 # 970.31.2

20 # - 90 # 990.20.2 green silicon carbide

100 # - 80 # 98.50.250.5

220 # - 240 # 97.50.250.7

W63 - W20970.30.7

W14 - W1095.50.30.7

W7 - W5940.30.7

46 # 2. The density, particle size (representative) and green silicon carbide is not less than 3.18 g/cm 3. Black silicon carbide is not less than 3.12 g/cm. 3. Size: shall meet GB2477-83 with the law of abrasive particle size and its 4. Ferroalloy particles allows content: # # 30 and with thick with without using 45 # screen ferroalloy is zero; 36 # 90 # # all through the sieve mesh granularity inspection in the lowest layer of iron alloy grain is zero; # 100 # and fine granularity sieve to check in with not by mixed grain of alloy is zero for the bottom of the screen. 5. Allow magnetic material content: 12 # to 240 # of content of magnetic material is not greater than 0.20%.

Silicon carbide < http://baike.baidu.com/view/9636.htm > purpose:

(1) as abrasive, abrasive tool can be used to do, such as grinding wheel < http://baike.baidu.com/view/33841.htm >, < http://baike.baidu.com/view/172063.htm >, grinding head < http://baike.baidu.com/view/574402.htm >, sand tile, etc.

(2) as a high temperature resistant materials and metallurgical deoxidizer < http://baike.baidu.com/view/841179.htm > < http://baike.baidu.com/view/1896744.htm >.

Silicon carbide has four main application fields, i.e., functional ceramics < http://baike.baidu.com/view/270476.htm >, senior refractories, abrasives and metallurgical raw materials. At present, the silicon carbide raw material has to a large number of supply, not < http://baike.baidu.com/view/2055546.htm >, new and high technology products and high technical content of nano-sized sic powder applied short time can't form scale economy.

(3) single crystals of high purity, can be used in the manufacture of semiconductor, the manufacture of silicon carbide fibers < http://baike.baidu.com/view/649472.htm >. Black silicon carbide known as the black silicon carbide particle size sand, black silicon carbide black silicon carbide particle size sand and black silicon carbide micro powder, two categories of products.

Is to use silicon carbide black silicon carbide particle size sand natural block after crushing, grinding, acid and alkali washing, water washing, drying, sieving classification technology, raw materials, quartz sand and anthracite coal or petroleum coke (Sio2) (c), above 1800 degrees Celsius heat generated under the condition of non-metallic minerals, it has high hardness, small expansion coefficient

联系方式:

巩义市久久抛光磨料厂

联系人:苏晨丹

电话:18939514537

座机:0371-60329928

传真:0371-60329928

QQ:1985802059

邮箱:1985802059@qq.com

网址:http://jiujiupgml.cn.alibaba.com

产品实拍图片:

联系方式:

巩义市久久抛光磨料厂

联系人:苏晨丹

电话:18939514537

座机:0371-60329928

传真:0371-60329928

QQ:1985802059

邮箱:1985802059@qq.com

网址:http://jiujiupgml.cn.alibaba.com