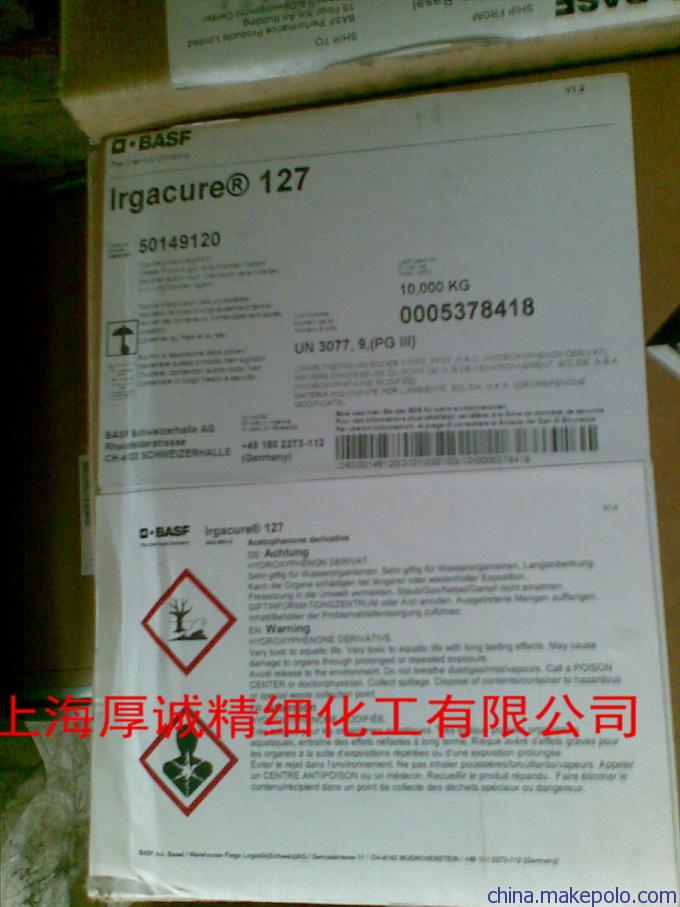

IRGACURE® 127

IRGACURE 127是一种新型高效不黄变的紫外光引发剂,用于引发不饱和预聚体系的UV聚合反应。它具有以下几个特点: l 与传统的α-羟基酮类抗氧剂相比具有更优越的反应性。 l 对氧的阻聚作用低敏感。 l 固化后低挥发和低气味。 IRGACURE 127特别适用于各种类型的UV墨水和透明涂层,特别是像复印清漆那样的薄涂层。 CAS No.:474510-57-1 外观:灰白色粉末 熔点:82-90℃ 吸收峰:259nm(在甲醇溶液中) 应

用: IRGACURE 127经过测试可单独使用或者与适当的引发剂混合使用。如与IRGACURE 379,IRGACURE 819混合时,吸收光谱红移,可用于UV固化油墨和普通半不透明体系。在这些应用中表现出非常高的固化速度和低气味,在UV固化油墨中(与其它光引发剂结合)提供显著的表面固化性。 低挥发性和对氧气阻聚作用的低敏感使IRGACURE 127在复印清漆(油墨)和木质地板顶漆方面有较好的效果。 上海厚诚精细化工有限公司 电话:021-34140679 传真:021-64369248 网址:chemhc.com

General

IRGACURE® 127 is a highly efficient UV curing additive which is used to initiate the photopolymerisation of reactive prepolymers - e.g. acrylates- in combination with mono- or multifunctional monomers.

IRGACURE® 127 is completely aligned with market requirements in terms of productivity and emission. This new photo-initiator is remarkable by its:

- excellent reactivity i.e. superiority over conventional a-Hydroxyketones like IRGACURE® 184 or DAROCUR® 1173;

- low sensitivity to oxygen inhibition;

- low emission and odor after curing.

IRGACURE® 127 is especially suitable for all types of pigmented UV-inks (offset, screen, flexo and Ink Jet) and Clear coatings, in particular in thin coatings like overprint varnishes but also in a variety of coating applications.

Chemical Structure

2-Hydroxy-1-{4-[4-(2-hydroxy-2-methyl-propionyl)-benzyl]-phenyl}-2-methyl-propan-1-one

Molecular weight: 340.4 CAS-No. 474510-57-1

Absorption Spectrum

(% in Acetonitrile)

Physical Properties

Appearance: off-white powder

Melting point:82-90 °C

Solubility at 22°C (g/100 g solution):

DAROCUR 1173 40 %

tripropyleneglycol diacrylate (TPGDA) 15 %

TMPTA 15 %

EBECRYL 160 15 %

OTA 480 >15 %

DPHA 5 %

Application

IRGACURE® 127 may be used after adequate testing alone or in combination with suitable co-initiators, such as IRGACURE® 379, IRGACURE® 819 for UV curable inks and in coating formulations for applications on paper, wood, metal and plastic materials. Its red-shifted absorption spectrum makes it especially suitable for UV curable inks and

in general semi opaque systems.

in these applications it delivers properties like very high cure speed and low odor. In UV curable inks it gives (in combination with other photoinitiators) outstanding surface cure properties.

Low sensitivity to oxygen inhibition associated with reduced emission are of particular interest for overprint varnishes and for top coats for wood parquets.

In UV curable cationic inks and coatings the use of IRGACURE® 127 as a co-initiator together with e.g. IRGACURE® 250 has been demonstrated to result in an exceptionally high-performance formulation.

The amount of IRGACURE® 127 required for optimum performance should be determined in trials covering a concentration range.

Recommended concentrations:

clears 1 – 6 % IRGACURE® 127

inks (free radical systems) 2 – 5 % IRGACURE® 127 combined with other PIs like e.g. IRGACURE® 379or IRGACURE® 819.

Inks (cationic systems) 0.5 – 2 % IRGACURE® 127 combined with other PI such as IRGACURE® 250

Safety and Handling

IRGACURE® 127 should be handled in accordance with good industrial practice. Detailed information is provided in the Safety Data Sheet.

IRGACURE® 127 is slightly sensitive to visible light and exposure to sunlight should be avoided. Opened bags should be closed immediately after use to protect the product against light.