中文名称: 橡胶预成型机

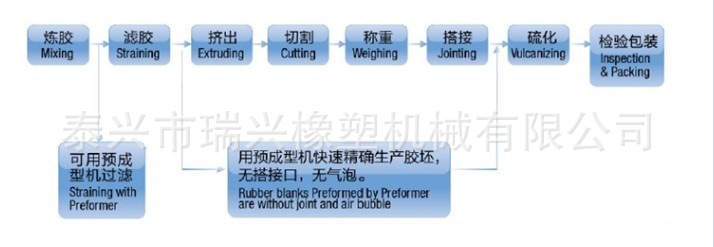

橡胶预成型是一种高精度高效率制胶胚设备,能生产高硬度,多种异形的胶胚,且胶胚精密度高,无气泡,适合生产油封、网球气门嘴、鞋底、医药、农业造粒等客户。

橡胶精密预成型是一种柱塞式为结构的机器,目前国内质量最好的是上海尚精机械设备厂研发生产的。主要由挤出装置、液压系统、真空系统、水循环系统、电加热系统、气动系统和切割系统以及电控系统组成。

1、挤出装置:由液压缸、料筒、机头等组成。

2、液压装置:选用高压齿轮泵。流量阀选用日本进口YUKEN(油研)产品。液压缸的液压油由流量阀控制,节流前后的压差阀始终控制在一个恒定值,保证准确的控制挤切胶坯的重量。

3、气动装置:用来控制机头开和关的动作。

4、真空系统:挤切胶料之前先行抽真空,排除机筒、机头内部的空气和胶料中夹杂的气体,从而提高下一工序硫化制品的质量。

5、加热系统:采用水循环加热方式,温度由数字式温控器控制和显示。保证机头、料筒的温度恒定。

6、切割装置:由机架、电机、减速系统组成。切割电机采用变频调速器达到无级调速,在机架下部安装有传送装置。

7、采用高清液晶触摸屏和进口PLC达到全自动控制运行。

8、采用电子称反馈系统通讯控制。

图片:

规格型号:

项目 | JY150 | JY200 | JY250 |

料筒内径 | 150 mm | 200 mm | 250 mm |

总功率 | 16 kw | 16 kw | 19kw |

油缸最大压力 | 36.8 Mpa | 20.7 Mpa | 17 Mpa |

料筒最高温度 | 95℃ | 95℃ | 95℃ |

口型最大直径 | 80 mm | 125 mm | 190 mm |

胶坯重量范围 | 0.3~100 g | 0.3~200g | 0.3~2000g |

胶坯重量精度 | ±1.0﹪ | ±1.0﹪ | ±1.0﹪ |

一次装胶量 | 8~10 kg | 20~25 kg | 60~70 kg |

切刀转速 | 35~300 R/M | 35~300 r∕min | 24~300 r∕min |

外形尺寸(L×W×H) | 4×1.1×1.7 m | 4×1.1×1.7 m | 5×1.1×1.7 m |

重量 | 2.8 T | 3 T | 4T |

英文品名:Rubber Precision Preformer (Barwell)

概述:

Rubber Precision performer is a high efficiency and high precision rubber blanks preparation equipment. Application in wide field of rubber industry can squeeze all kinds of middle and high hardness of rubber ring, the complex three-dimensional shape of rubber product. And the precision of rubber blank volume is high, less gas. Suitable for production of rubber parts, seals, valve, cork, tennis.

Rubber Precision pre-forming machine mainly compose of a plunger extrusion equipment and a set of rubber blanks in the machine head cutting device and, in addition with a hydraulic system, vacuum system, heating systems, pneumatic systems, and electrical systems. Pre-work precision machine, open the nose or the lid , feed the preheated rubber materials through the front barrel mount or charging inlet, and then close the head (lid), set extrusion speed and Cutting speed (supplied volume control chart), vacuum, cutting, accurate weight of rubber parts can be obtained.

Introduction of rubber precision performer:

1. Extruder device: composed of hydraulic cylinders, cylinder, head etc.

2. Hydraulic System: (Pump selection). Hydraulic machine, sealing systems and pressure pipe joints is through the repeated selection of more after being stereotyped, mostly using imported parts and the joint venture enterprise products, which fundamentally changed the previous domestic production of oil leakage phenomenon of hydraulic equipment.

3. Pressure Display: The system displays the pressure difference for advanced digital mode, the system pressure regulation and control is more precise, convenient, compared with similar products, save the addition and subtraction in phase between the two pressure gauges to method of operation to obtain the pressure difference, time-consuming and inaccurate.

4. Pneumatic device: used to control head switch (closed) cylinders and other activities.

5. Electric Control System: Siemens of Germany and Japan Fuji products, motor from ABB company, and greatly reduces the equipment failure rate of the production process, improve machine reliability, stability and service life.

6. Vacuum system: before extruding and cutting, using vacuum system to remove the air and gas in barrel, head, inside the compound mixture, thereby enhancing the quality of products under the curing process.

7. Heating System: The water cycle heating mode, temperature control by a digital thermostat and display. Ensure nose, barrel temperature constant.

8. Cutting device: composed of the frame, motor, inverter system.

9. Operating system: semi-automatic and manual operation mode of two options, allowing users to operate in the actual use of flexible and convenient situation.

10. Machine's structure, adopt the latest design ideas abroad, beautiful appearance.

Specifications on rubber precision performer

Specification:

Model | JY150 | JY200 | JY250 |

Barrel diameter | 150 mm | 200 mm | 250 mm |

Total power | 16 kw | 16 kw | 19kw |

Max.oil cylinder pressure | 36.8 Mpa | 20.7 Mpa | 17 Mpa |

Max.barrel temperature | 95℃ | 95℃ | 95℃ |

Max. die diameter | 80 mm | 125 mm | 190 mm |

Rubber bland weight range | 0.3~100 g | 0.3~200g | 0.3~2000g |

Rubber blank weight precision | ±1.0﹪ | ±1.0﹪ | ±1.0﹪ |

Feed capacity per batch | 8~10 kg | 20~25 kg | 60~70 kg |

Blade rotation speed | 35~300 R/M | 35~300 r∕min | 24~300 r∕min |

Dimension(L×W×H) | 4×1.1×1.7 m | 4×1.1×1.7 m | 5×1.1×1.7 m |

Weight | 2.8 T | 3 T | 4T |