| ||

|

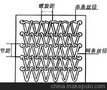

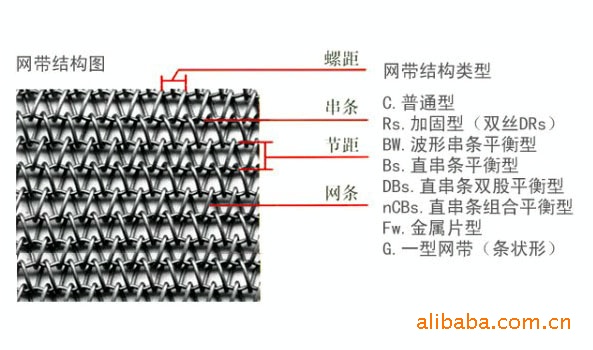

网带规格: 链条标号节距P链杆节距P1链杆直径D网丝直径D1网带螺距L网带节距J

(P)(p)(p1)(D)(D1)(L)(J)

C2042 25.4mm 25.4×*节5~8mm 1.0~1.6mm 3~19mm 6.35~25.4mm

C2052 31.75mm 31.75×*节6~10mm 1.2~2.0mm 5~21mm 6.35~31.75mm

C2062 38.1mm 38.1×*节8~12mm 1.5~2.0mm 8~21mm 6.35~38.1mm

C2082 50.8mm 50.8×*节10~12mm 1.5~3.0mm 10.5~21mm 12.7~50.8mm

C2160 101.6mm 101.6×*节10~14mm 1.5~4.0mm 10.5~27mm 12.7~50.8mm

丝径1.2、1.4、1.6、1.8、2.0、2.2、2.4、2.6----4.5不等

[编辑本段]

网带选择参考 怎样选择输送网带的各种材料

How to specify material of various conveyor belts

材料名称

Designation | C | Mn | Si | Ni | Cr | 其他元素

Other elements | 性能properties |

|

耐温

Temperature

-resistance | 耐酸

Acid resistance |

|

|

|

|

|

|

|

1~3号乙类钢

GB700-65 | 0.06~0.22 | 0.25~0.6 | 0.12~0.3 |

|

|

| 300° | 耐磨

Abrasion resistance |

1Cr13 | ≤0.12 | ≤0.60 | ≤0.60 |

| 12~14 |

| 600° |

|

1Cr18Ni9 | ≤0.08 | ≤2.00 | ≤0.80 | 8~11 | 17~19 |

| 600°~700° |

|

1Cr18Ni9Ti | ≤0.08 | ≤2.00 | ≤0.80 | 8~11 | 17~19 | Ti0.8 | 700°~750° | 做防酸防锈腐蚀

Acid rust and corrossion resistance |

OCr18Ni12Mo2Ti | ≤0.08 | ≤2.00 | ≤0.80 | 12~14 | 16~18 | Ti0.3~0.8

Mo1.8~2.5 | 750° |

|

OOCr18NIi14Mo2 | ≤0.03 | ≤2.00 | ≤1.00 | 12~16 | 16~19 | Mo1.8~2.5 | 700°~800° | 耐酸腐蚀

Strong-acid resistance |

1Cr25Ni20 | ≤0.20 | ≤2.00 | ≤1.00 | 17~20 | 22~25 |

| 1000° |

|

OCr25A15 | ≤0.06 | ≤0.7 | ≤0.6 |

| 23~27 | A1 4.5~6.5 |

|

|

Cr20Ni80 | ≤0.15 | ≤0.7 | 0.4~1.3 | 75~78 | 20~23 | A1≤0.5 | 1150° |

|

OOCr18Ni14Mo2Cu2 | ≤0.03 | ≤2.00 | ≤1.00 | 12~16 | 17~19 | Mo1.2~2.5

Cu1.0~2.5 |

| 耐重酸重腐蚀应用在维尼纶厂的醛化机上

Strong-acid resistant can be used cerbonylator on vinylon |

长城网带技术参数:

网带型号 | 金属条厚度㎜ | 金属条宽度㎜ | 螺距㎜ | 节距㎜ | 串条直径 | 网边型式 |

FW2.5/8.0 | 2.5 | 20 | 31 | 27.3 | 8.0 | 1、马蹄链型式

2、链条型式

3、镦头型式样 |

FW2.0/8.0 | 2.0 | 22 | 40 | 50.8 | 8.0 |

|

FW2.5/2.5 | 2.5 | 16 | 37.4 | 28.3 | 5.0 |

|

FW2.0/5.0 | 2.0 | 15 | 52.5 | 31.75 | 5.0 |

|

FW1.5/3.0 | 1.5 | 12 | 52.5 | 31.75 | 3.0 |

|

FW1.2/3.0 | 1.2 | 10 | 22.5 | 12.7 | 3.0 |

|