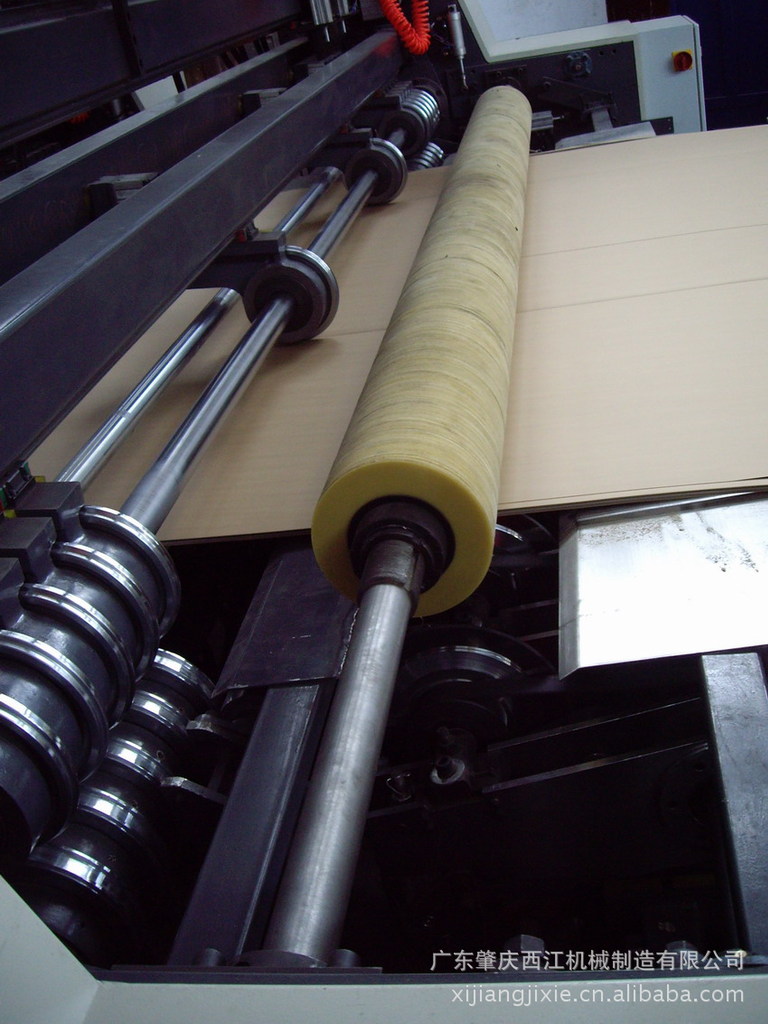

计算机控制薄刀分纸压线机

Computer Control Super Thin Blade Slitter Scorer

l 欧洲航天级伺服控制系统,主机纵切刀及压线轮独立单元伺服马达控制,1秒内高速排单、定位精准。

l European aerospace type servo control system, Slitting knife and Line pressing wheel are controlled by independent servo motors. High speed order arrangement andprecise positioning within 1s.

l 适配于高速生产线实现无缝隙的连续生产。

l Applied to high-speed production line, can achieve seamless and constant production.

l 远程监控:支持通过以太网或3G无线网卡实现远程监控,实现快速维护,提高生产效率。

l Remote monitoring: remote monitoring through or 3G wireless card to achieve fast maintenance and improve efficiency.

l 下切式分纸的独特设计,切边精准、印刷面无毛刺、满足纸板与纸箱生产的高效生产,降低印刷过程的停机率。

l Unique design of down-cutting to ensure the edge of the cardboard precise, and the smooth face without glitch, can meet the high efficiency of production and reduce stop rate of printing.

l 配预压装置,可适应任何克重纸板压痕凸压凹,凸压凸和凸压平等多元化压痕选择,线型转换时间<1s

l With pre-pressure device,can suit cardboard creasing of any weight, multi-type of scorer are available: convex pressed to concave, convex pressed to convex, convex pressed to plane,time of line type change less than one second.

l 全自动吸废系统、可根据订单的转换时左右吸废口位置跟随边刀自动调整。

l Fully-automatic absorb waste system; location of absorb waste can automatically adjust to follow the knife ording to the order change.

l 整机可选配自动纠偏系统,适应生产线运行路线的自动追踪,无需人工调节。

l Optional automatic correction system, adapt automatically track running routes of production line, without manual adjustment.

l 最小压线距离:118mm或0 mm,压线间隙调整:1-10mm

l Minimum Press Line Distance: 118mm or 0 mm, Press Line Gap Adjustment: 1-10mm

l 工作宽幅:1800mm,2200 mm,2500 mm

l Working Width: 1800mm, 2200mm, 2500mm

l 最高速度:300m/min

l Max. Speed: 300m/min

l 最小纵切距离:145mm

l Minimum Longitudinal Distance: 145mm

l 纵切刀配置:4,5,6,7

l Slitting Knife Configuration: 4,5,6,7

l 压线轮配置:6,8,10,12

l Pressure Line Wheel Configuration: 6,8,10,12

l 排单精度:±0.5mm

l Order Arrangement Precision:±0.5mm

1 高速高精度纵切机——贝加莱AcoposMult系统High-speed and high precision slitting machine - B & R AcoposMult system

1.1 电气配置Electrical configuration

n 贝加莱全伺服方案

B & R servo programs

n CPU:贝加莱(欧洲原装进口)

CPU:B&R (Europe imported)

n HMI显示屏:贝加莱(欧洲原装进口)

HMI Display: B & R(Europe imported)

n IO:贝加莱(欧洲原装进口)

IO:B & R(Europe imported)

n 驱动器:贝加莱(欧洲原装进口)

Drive:B & R(Europe imported)

n 电机:意大利电机

Motor:Italian motor

n 编码器采用德国施克Sick多圈绝对高精度编码器(识别精度:100万分之一度)

Encoder is Sick Germany multi-turn absolute high-precision encoder (Recognition uracy: 100 parts per million degrees)

n 变频器: AB

Inverter: AB

n 电气元件:施耐德

Electric components: Schneider

1.2 特点Featuresn 欧洲奥地利原装进口。PLC、触摸屏、IO、伺服驱动器都采用欧洲奥地利原装进口。

Europe Austria imported. PLC, Touch screen, IO, Servo drives are imported from Austria, Europe.

n 高速高精度。主机纵切刀及压线轮独立单元伺服马达控制,1秒内排单、定位精准.

High-speed high precision. Slitting knives and line pressing wheel independent servo motor control, order arrangement within 1 second, precise positioning.

n 无需上电调零,无累积误差。采用多圈绝对编码器之后,无需每次上电教零位,无累积误差。

Zero-arrangement without electricity, no umulated error: adopt multi-turn absolutely encoder to achieve no umulated error and zero-arrangement without electricity.

n 零废纸换单。配合废纸刀,实现高速生产线零废纸换单。

Can change order without waste paper. Withrotary sheet cutter, to achieve no waste paper during high-speed production.

n 全自动吸风口系统。吸风口由伺服电机精准控制,跟随边刀自动调整。

Auto suction outlet system. Suction outlet controlled by servo motor precision, following the knife edge automatic adjustment.

n 全自动压痕深浅系统。根据纸板层数和纸板压痕深度,自动调整压痕深浅。

Auto creasing depth control system. Indentation ording to depth of creasing and cardboard layers, automatically adjust the depth of indentation.

n 自动纠偏系统。整机可选配自动纠偏系统,适应生产线运行路线的自动追踪,无需人工调节。

Auto correction system. Optional auto-correction system, automatic tracking running routes of production line, without manual adjustment.

n 微调功能。支持生产过程中对部分刀轮和线轮进行微调。

Micro adjustment functions. Support parts of line wheel and knife wheel micro adjustment during the production.

n 支持键盘输单。

Support order keyboard input.

n 支持生管输单和换单。采用标准通讯接口,支持生管输单和换单。

Support production management input order and order changed. Standard communication interface, production management and change orders.

n 支持远程操作和远程维护。

Support remote operation and remote maintenance.

n 采用欧洲航天用的VxWork操作系统,比Windows更可靠,减少故障停机概率。

Using European Aerospace VxWork operating system,more reliable than Windows, reducing the probability of downtime.朗读显示对应的拉丁字符的拼音

1.3 电控部分架构STRUCTURE OF ELECTRIC-CONTROL PART

贝加莱触摸屏+贝加莱IO+贝加莱伺服驱动器。

B&R Touch Screen + B&R IO + B&R Servo Drives

1.4 贝加莱驱动器(欧洲原装进口)B & R (EUROPEAN IMPORTED)

采用模块化设计,便于扩展。Adopt modularized design, easy to extend.

双轴驱动模块:此驱动器可以同时独立驱动两套电机,集成化高,体积小。

Double-shaft drives module: can drive two sets of motors independently at the same time, high integration and with small volume.

AcoposMulti驱动器,在全球纺织、印刷等需要高速高精度行业已经广泛应用,质量可靠。

AcoposMulti drive is of high quality and high stability, it has been extensively applied to many industries in the world, which need high speed and high precision, such as spin and painting.

屏、PLC和伺服之间采用1000M工业实时以太网通讯。高速网络为设备的稳定可靠保驾护航。

Screen, PLC and servo can be communicated through industrial 1000m . The high speed can ensure the stability of devices

1.5 故障维护BREAKDOWN MAINTENANCE

尽量减少停机时间。

Reduce stop time.

电机和伺服互换性,是指在实际生产中,某台电机或者伺服坏了之后,是否可以用相对不重要的电机或者伺服替换的容易程度。例如,7刀12线中的中刀电机或者伺服坏了,是否可以用最边上的第7刀代替中刀,设备以6刀12线生产。The exchange of motor and servo means that once one motor or servo doesn’t work, it possible to be replaced by other less important motor or servo. For example, if the middle motor (of 7 slitter 12 scorer) or servo is out of work, it possible to replace the middle knife with the 7thknife, then it turns to 6 slitter 12 scorer.

贝加莱全伺服方案B&R Servo Plan

n 互换性强。

With high interchangeable.

n 伺服的站号通过外部拨码改变。

Number of servo station changed by outer code

n 售后服务量少。

Less after-sale service

n 普通工人就能完成电机的互换。

Motor-exchange can be finished by common worker.

1.6 售后After sales

n 远程故障诊断和维护。触摸屏PLC带有以太网接口,支持有线和3G等网络,可以实现远程故障诊断和维护。

Remote monitoring and maintenance: Touch screen PLC with interface, support wired and 3G network to achieve remote monitoring and maintenance.

n 统一品牌,无缝连接。PLC和伺服驱动器采用同一品牌,可实现无缝连接,便于对伺服驱动器诊断和维护。

Unified brand, seamless connectivity.PLC and servo drive use same brand, can achieve seamless connectivity, easy to diagnostics and maintenance of servo drive.