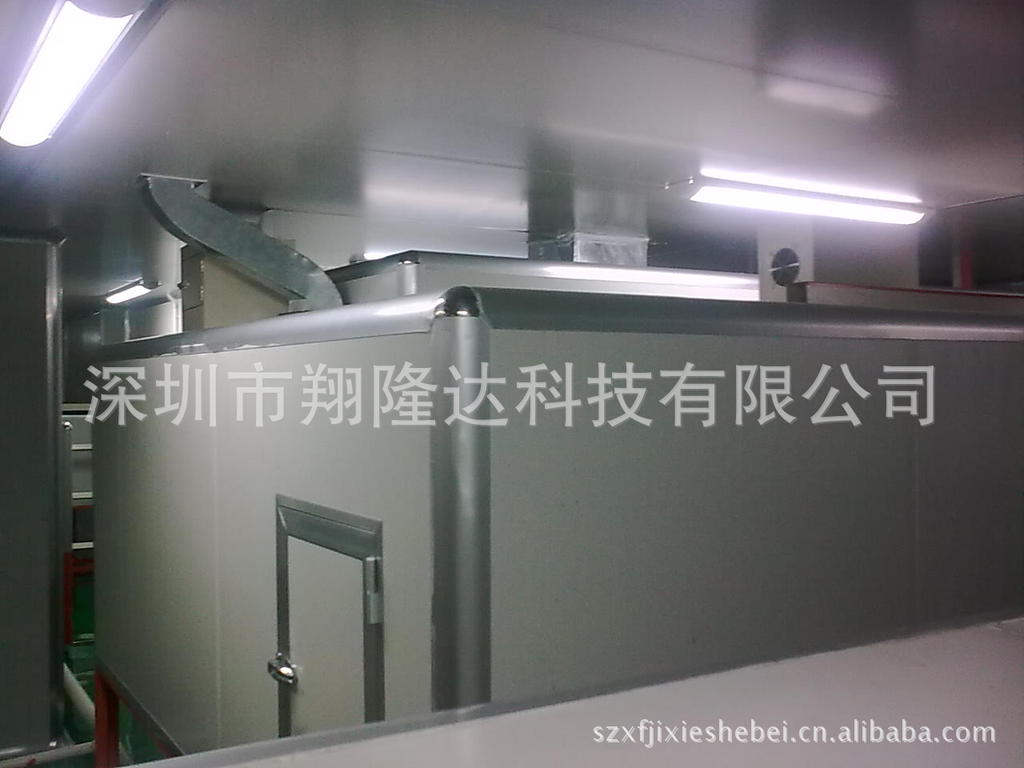

我公司专业制作的新型自动化喷油生产线设备、油漆喷涂均匀、效率高、人力少,全自动连续24小时作业、产量大、效率高、涂层面均匀,比一般喷涂设备产量大3-4倍。PU/UV漆两用配套无尘车间生产,有效地控制产品外观质量,满足了客户对品质的需求,增强公司产品在市场的竞争能力又赢得了客户信任。

工艺资料:

1.输送速度:V=0-8米/min变频调速。

2.工件自转:V=10-200R/min变频可调。

3.产量:500-5000件/h(视工件大小及挂件方法计量)。

4.喷枪数:每喷房6-8支喷枪(视喷涂需要可增或减少)。

5.涂装方式:工件正反自转配合各角度固定喷枪循序喷涂。

6.喷房:万级设计,水洗无尘喷房、负压排气。

7.供风:可按无尘等级需求规划不同等级供气过滤系统。

8.烘烤:远红外线加热、温度:Tmax=100℃±3℃可调。

9.控制:采用可编程PLC控制,来料自动检测、喷涂。

工艺流程:(以2涂2烤为例)

上件→人工除尘→自动静电除尘→自动喷底漆→流平→烘烤→自动喷面漆→流平→烘烤→ UV固化→下件。

产品说明:

工件自转自动喷涂机(一涂一烤,二涂二烤,三涂三烤,另加UV固化)

一、适用产品:

手机、相机、MP3、音箱、玩具、化妆品盒、键盘、鼠标.相机、DVD等。

二、喷涂流程:

1上料-2人工静电除尘-3自动静电除尘-4自动

喷涂-5静置烘烤冷却-6 UV固化-7下料. (每增

加一涂一烤3、4、5工艺需增加一组设备).

产品说明:

工件自转自动喷涂机(一涂一烤,二涂二烤,三涂三烤,另加UV固化)

一、适用产品:

手机、相机、MP3、音箱、玩具、化妆品盒、键盘、鼠标.相机、DVD等。

二、喷涂流程:

1上料-2人工静电除尘-3自动静电除尘-4自动

喷涂-5静置烘烤冷却-6 UV固化-7下料. (每增

加一涂一烤3、4、5工艺需增加一组设备).

三、外观尺寸: L 16 m x W 6 m x H 3 m.(根据客户车间与产品情况而规划)

四、工艺资料:

1.链条输送速度: 0-8 m/min.

2.工件自转速度: 10-200 r/min.

3.工件尺寸:直径300 mm*高度400 mm.

4.产量: 400-8000件/ h (依工件大小变动).

5.喷枪数:喷枪数量:2-12支(视产品而定)

6.喷涂方式:

工件自转(正转、反转)配合各角度喷枪循序喷涂.

7.喷房:三面水洗、涡漩水流、负压排气.

8.补风:

可依无尘等级需求规划不同等级之供气过滤系统.无尘正压鲜风补给,经初效、中效、中效、高校四层过滤配合涡旋式喷房,正压喷涂。链条输送至彩钢板岩棉烤箱,远红外发热管烘烤,进口温控分段控制,可加UV固化炉,无尘房车间万级至静态万级动态十万级。

9.烤箱:

彩钢外观、远红发热、岩棉隔热、SCR分控.可搭

配UV固化炉施工.

10.操作方式:

人机界面采用可编程PLC可编程式触摸显示屏,.来料自动感人机介面控制,红外线感应,来料自检测,自动喷涂.

五、特点:

喷涂速度快,喷涂均与,依工件变化,自动调整喷枪,高低、前后、角度位置,可配合打版机模拟程序,减少停线调枪打样时间、喷枪条件数位化记忆,减少对师傅的依赖,生产管理容易。

Our company specializes in the production ofnew typeautomatic injectorproduction line equipment,paint sprayinguniformity,high efficiency,little manpower,full automatic continuous24 hour operation,large output,high efficiency,uniformcoatingsurfacespraying equipment,than the averageyieldof 3-4 times.PU/UV paintdual-purposesupportingclean workshop production,effective control ofappearance quality of products,to meetcustomer demand for quality,enhance the company s products inthe competitive ability of the marketandwin customer trust.

Process data:

The 1 conveyorspeed: V=0-8m /minvariable frequency speed regulation.

2:V=10-200R/minworkpiecerotationfrequency adjustable.

3output:500-5000/h(as thesize of the workpieceand thependantmethodmeasurement).

4: the number ofeachspray gunspray room6-8guns(as thesprayingneedmay increaseor decrease).

5:the positive and negativerotation ofworkpiececoating methodwith thefixed anglesequentialsprayinggun.

6spray room:millionlevel design,washedclean sprayroom,a negative pressure exhaust.

The 7air supply:according todifferent grades ofcleangraderequirements planningairfiltration system.

8:far infraredheating,bakingtemperature:Tmax=100 ℃± 3℃ adjustable.

9control: usingprogrammable PLCcontrol,automatic detection,sprayingmaterials.

Process:(2Tu grilled 2as an example)

The partsand artificialprecipitation,automatic electrostatic dust removingautomatic sprayprimer →→→→automaticlevelingbakinglacquer→→→ UVlevelingof bakingcuringtopieces.

Product description:

Workpiecerotation automaticspraying machine(one coatingroasted,bakedtwoTu two,threewiththree grilled,plusUV curing)

One,the suitable products:

Mobile phone,camera,MP3,speakers,toys,cosmetics boxes,keyboard,mouse,camera,DVD etc..

Two,sprayingprocess:

The 1feeding2artificialelectrostatic dust- 3automatic electrostatic dust- 4automatic

Spray- 5staticbakingcooling- 6UV curing7(each additionalmaterial.

Acoatedbake for 3,4,5technologyneeds to add agroup of equipment).

Product description:

Workpiecerotation automaticspraying machine(one coatingroasted,bakedtwoTu two,threewiththree grilled,plusUV curing)

One,the suitable products:

Mobile phone,camera,MP3,speakers,toys,cosmetics boxes,keyboard,mouse,camera,DVD etc..

Two,sprayingprocess:

The 1feeding2artificialelectrostatic dust- 3automatic electrostatic dust- 4automatic

Spray- 5staticbakingcooling- 6UV curing7(each additionalmaterial.

Acoatedbake for 3,4,5technologyneeds to add agroup of equipment).

In three,the appearancesize:L16 mxW 6mxH 3m.(according to customer sworkshop andproduct situationplanning)

Four,process data:

The 1conveyorspeed: 0-8m/min.

The 2 workpiecerotationspeed: 10-200r/min.

The 3workpiece size:300 mm* in diameter andheight of 400mm.

4Output:400-8000/h(according toworkpiecesize changes).

Gun:gunnumber5numbers:2-12(depending on the product.)

6spraying method:

Workpiecerotation(forward,reverse)with theangle ofsequentialsprayinggun.

7:threespraywashing,vortexflow,a negative pressure exhaust.

The 8air supply:

According todifferent gradesofcleangraderequirements planningairfiltration system.Cleanpositive pressurefresh airsupply,theearly effect,in effect,in effect,thefour layers of filterwithswirlspray room,positive pressurespraying.Chain conveyortocolor plateYanmianoven,far infrared heatingtubebaking,imports of temperature controlsubsection control,it may be added with UVcuring oven,dust-freeworkshop10000millionlevelone hundred thousand level dynamictostatic.

9 oven:

Colorappearance,far infraredheating,rock woolinsulation,SCRcontrolcan catch

WithUV curing furnaceconstruction.

The 10mode of operation:

The man-machine interface adoptsprogrammablePLC programmabletouchscreen,automaticmovingmachine.The incominginterface control,infrared sensor,incomingself detection,automatic spraying.

Five,features:

Fast spraying speed,sprayand,according to thechanges of the workpieces,automaticadjustment ofspray gun,height,angle,andposition,can be matched witha version ofsimulation program,reduce thestopping lineadjustablegunproofing time,sprayconditionsdigitalmemory,reducingdependenceonmaster,easyproductionmanagement.