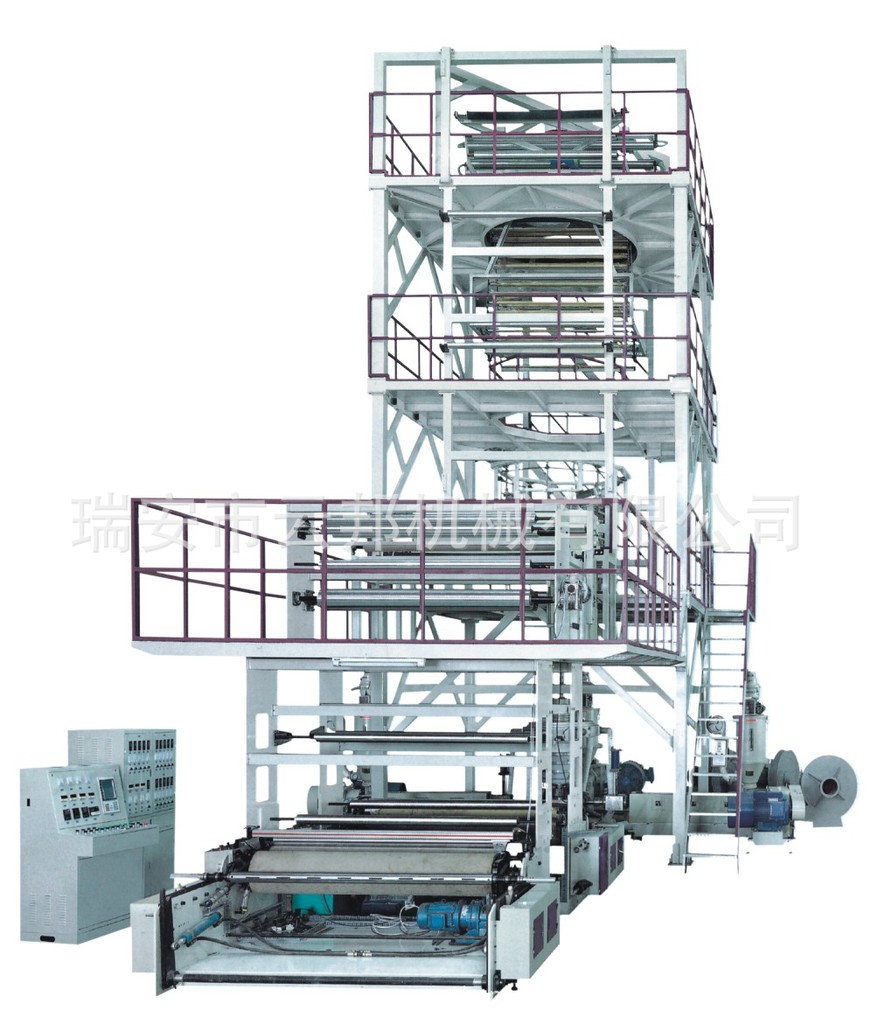

三层共挤薄膜吹塑机组(IBC膜泡内冷)

Three-layer Co-extrusion Film Blowing Machine(IBC SYSTEM)

特点/CHARACTERISTICS

1、全新型挤出技术,产量大(产能提升30%以上),而且塑化性能好。

2、全新技术中心进料螺旋式模头,结构紧凑、快速更换配方、节约原料。

3、IBC膜泡内冷装置,不仅提高产量,节约能耗,更可以提升薄膜制品的质量。

4、水平式薄膜旋转牵引系统,大大提升薄膜卷质量,杜绝荷叶边现象,适应高速印刷、复合工序处理。

5、全自动双工位收卷机,具有自动换卷、切膜、计米功能。

6、精密双风口负压风环。

7、机架表面全部采用先进烤漆工艺处理,外表美观大方,使用寿命长,防锈性能出众。

8、吹膜设备重点强调设备的经济性,高产能和低能耗,具有良好的性能价格比,诚为广大客户的理想选择。

1、Newtech of extrusion, large capacity(more than 30% capacity increase), good plasticizing performance.

2、Advanced technique of central-fed compact die head,cmpact structure, quick-change formula, saving raw materials.

3、IBC(internal bubble cooling) system to improve the output, reduce energy consume, get better product quality.

4、Horizontal type reversing haul-off system to improve film quality, avoid edge wrinking,be suitable for the process of high-speed printing and multi-operation.

5、It adopts full-automatic double-station winding system, automatic roll changing, automatic cutting, meter counting functions.

6、Precise double-lip air ring.

7、The surface of the machine frame is processed by advanced paint technology with long using life and superior anti-rust performance,

8、Incorporating many latest technologies to get higher output, better film thickness tolerance, and lower power consumption, and gain more value for the customers.

主要技术参数/Main Technical Parameter

型号Model | SJ-GS1700 |

层数Layer | 3 |

薄膜最大折径Max. film lay flat width | 1600mm |

薄膜最大厚度Film thickness | 0.03-0.12mm |

最大产量Max. Output | 250-300kg/h |

使用原料Resin | mLLDPE, LLDPE, LDPE, EVA |

螺杆直径Screw diameter | Φ55\Φ65Φ\55mm |

螺杆长径比Screw L/D ratio | 30:1 |

螺杆最大转速Max. screw rotation speed | 120r/min |

主电机功率Power of main motor | 22/37/22kw |

膜泡冷却形式Bubble cooling mode | 精密双风口负压风环,IBC膜泡内冷系统 Precise double-lip air ring, IBC(internal bubble cooling)system |

旋转牵引形式Haul-off type | 不平式360度,旋转牵引系统 Horizontal type 360 degree reversing haul-off system |

牵引速度Haul-off speed | 45-12m/min |

总功率Total power | 220kw |

外型尺寸(L*W*H)Overall dimensions | 11000*7000)10000 |

重量Total weight | 30T |