总经理:杜奉刚 联系电话:15098680111

销售经理:徐萍 联系电话:15005455988

传真:0535-2830567 电话:0535-2830567

电子邮箱:shuguang03@LZshuguang.com

MSN:shuguang121@hotmail.com QQ:2387487810

公司地址:山东省莱州市土山镇工业园区

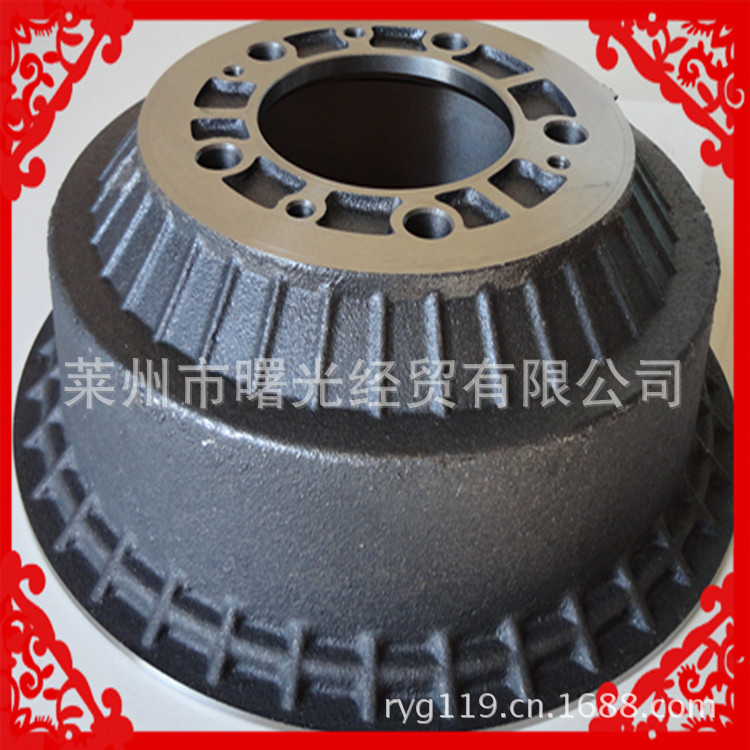

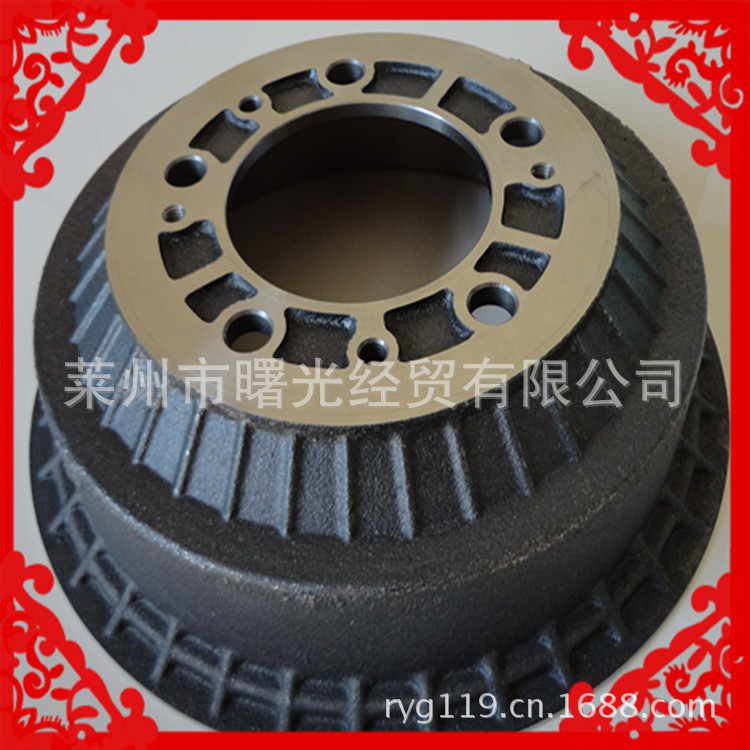

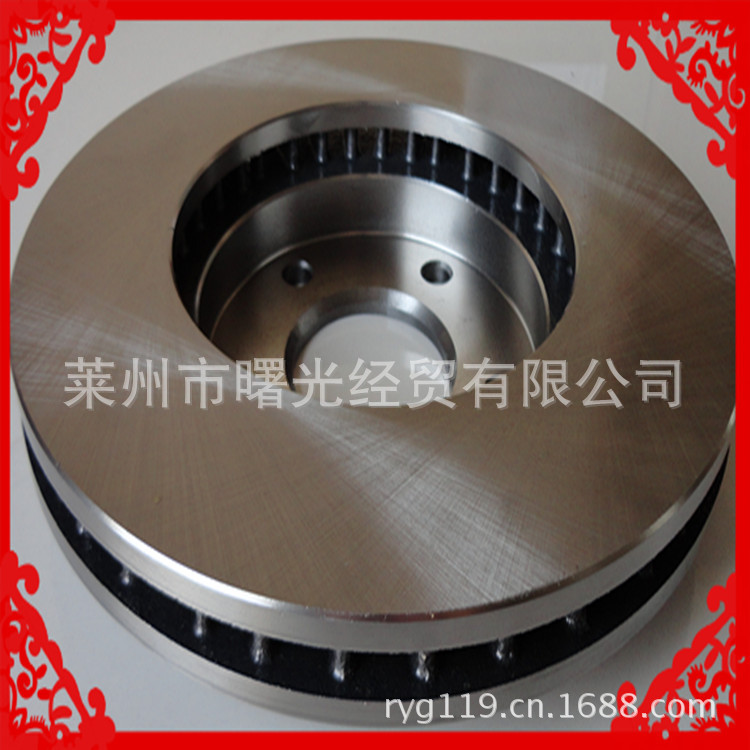

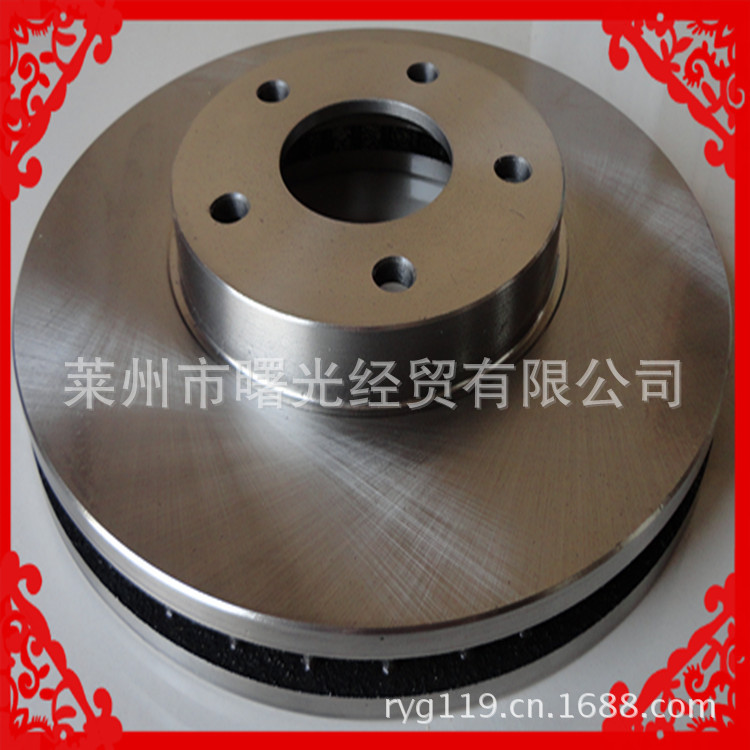

山东莱州曙光经贸有限公司成立于2006年,公司位于莱州土山工业园,是汽车刹车盘、刹车鼓的专业生产厂家。公司现有职工100余人,其中技术人员10名,产品远销欧洲、北美、南美、中东、东南亚、北非等国家和地区,年出口额500多万美元。

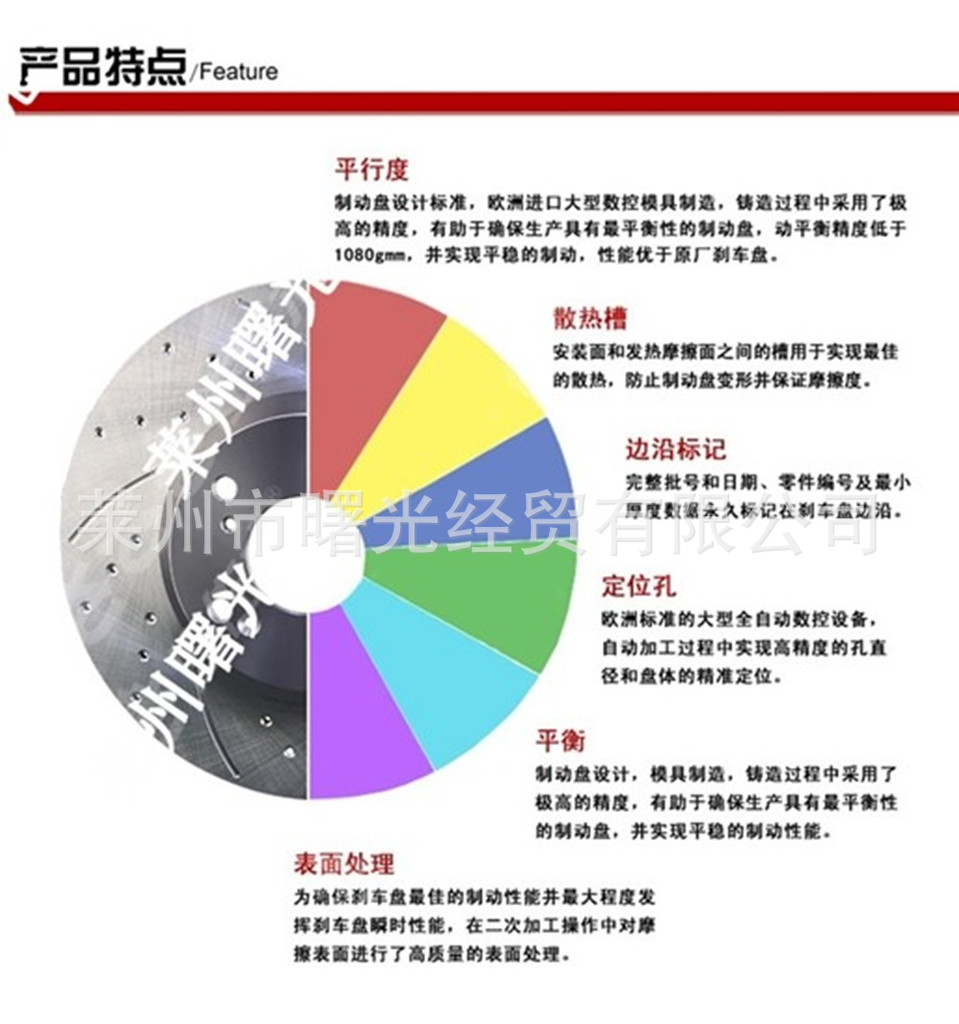

公司现有锻打车间、铸造车间,机加工车间,多条先进的生产线及专业的刹车盘生产设备:数控动平衡机、数控打标机、精光机、磨花机等,能满足客户的各种加工要求。所用刹车盘毛坯均为自己生产,从而能够保证刹车盘毛坯质量的长期稳定。产品已通过ISO9001质量体系认证,现有刹车盘、刹车鼓,刹车锅,改装盘2300多种型号,适合国内外各种车型,也可来样来图生产并能根据客户的不同要求生产磷化、覆膜砂、高速、改装、喷漆、电泳等各种刹车盘。我们每年开发超过500种新型号,每天都有新产品诞生。公司拥有大量先进、专业的生产设备和检测仪器,执行严格的质量控制体系,化验、检测设备齐全,保质保量,供货及时。

我们工厂生产不是最早,我们的规模也不是最大,但我们有信心把工厂做的最好,把品质做的最优,把高质量的产品及时的交给您。公司秉承“顾客至上,保证质量,锐意进取”的经营理念,坚持“客户第一,薄利多销”的原则为广大顾客提供优质的产品。欢迎有识之士惠顾!

Laizhou Shuguang Economic & Trade Co.,Ltd was founded in 2006, which is located in Tushan industrial park, Laizhou city,Shandong province. Our company now has more than 100 employees which include 10 technicians.Our company is specialized in manufacturing auto car brake disc and brake drum.Our products are well sold to Europe,North & South America,Middle East, Southeast Asia and North Africa with the exports over $5,000,000.

We have forging workshop, casting workshop and machining workshop,with a number of advanced production line and professional brake disc production equipment such as CNC dynamic balancing machine, NC marking machine,etc, which can satisfy all kinds of customer’s processing requirements.All of the blanks are self-production to ensure the blank quality long stable. The products has passed the ISO0001 quality system certification and now we have more than 2000 types of brake discs, brake drums and refitting discs which are suit for various kind of cars both at home and abroad. We also product with sample and drawing and supply brake discs with phosphorization, precoated sand,high-speed, refitting,painting,electrophoresis according to the customer’s requirement.We develop more than 500 kinds of new types every year and new items producted every day.Our company has a range of advanced and professional production equipments and detecting instruments,carry out the strict quality control system,complete of testing and analysis equipments with the quality and quantity guaranteed & timely delivery.

Our company was not the earliest founded and our scale was not the largest,though,we have the confidence to do our best for the factory with the best quality,only for giving you the product with highest quality in time.our company always adhering to the “customer first, quality assurance, forge ahead”, insist the principle of”customer first,small profit by quick turnover” to serve superior products, We welcome to negotiate!

鼓式刹车的刹车性能比盘式刹车的差吗?

在技术角度看,鼓式刹车的刹车性能并不比盘式刹车差。两者的差别是盘式刹车有更高的耐热性和较轻的重量。而鼓式刹车由于刹车片内藏在刹车鼓,因此刹车时产生的热量很难散发于空气中,散热效果不及盘式刹车好。

为什么大部分的汽车都是前刹车盘比后刹车盘大?

大部分汽车的发动机都是安装在车的前方,与发动机相连的变速箱是车上质量最大的部件,另外多数汽车都是前轮驱动,所以车前轴要比后轴负但更高的重量,加上刹车时车的重量也会向前转移,因此前刹车要负责大部分的刹车工作。(在极端的情况下如:下坡+急刹车,90%的制动力由前刹车负责)。反看后刹车在大部分的时间里只负责约1/3的刹车任务。因此除了后轴比前轴重的汽车(如发动机后置的超级跑车),大部分汽车前刹车盘都比后刹车盘大。

升级刹车系统后便可以确保安全了吗?

在同一条件下升级的刹车系统则具备更高的刹车效能,但是在驾驶的时候还是要按照交通道路行驶法来进行正常驾驶。主动安全意识要高于任何的被动安全措施,还要注意轮胎和路面的摩擦力是非常重要的一环。如果路况太差,或是轮胎抓地力太弱,或是任何一方不匹配,升了级的刹车只会提前把车轮抱死,对缩短刹车距离没有帮助。因此建议刹车升级后应同时把轮胎升级,在路况不好的地方必须小心驾驶。

在什么情况下需要进行刹车盘的维护?

1.每当车行驶4万公里左右时就应该进行一次刹车盘维护,因为行驶几万公里,已经经过无数次的刹车制动,刹车时产生的几百度高温极易使刹车盘产生变形,并且使盘面产生细小的沟纹,此时如果刹车盘不进行光秀维护,盘面变形会加剧,沟纹会变成沟槽,并且会越变越深,致使刹车盘的使用寿命大大缩短。

2.当刹车时抖动,异响,刹车效果差,刹车盘面出现沟槽,边台时就更需要进行光修维护了。