Lexan进口耐力板 6mm 透明MR5E聚碳酸酯抗划伤 表面硬化pc板

产品简介

Lexan* Margard* MR5E板材是一种透明的,具有双面抗UV和耐划伤涂层、表面光滑,适合平面应用的产品。该款产品采用了Lexan聚碳酸酯材料并结合了先进的双面涂层技术,使得其不仅具有高冲击强度和防破坏的特性,还有防涂鸦和优秀的耐候性,可保证10年不会发生脆裂,7年内不会发生黄度以及透光率、涂层性能的显著改变。

性能 | 测试方法 | 单位 | 指标 |

物理 | |||

密度 | ISO 1183 | g/cm3 | 1.20 |

吸水率, 24 小时 | ISO 62 | mg | 10.0 |

机械性能 | |||

屈服拉伸强度 | ISO 527 | MPa | 60 |

断裂拉伸强度 | ISO 527 | MPa | 70 |

屈服拉伸应变 | ISO 527 | % | 6 |

拉伸模量 屈服 | ISO 527 | MPa | 2350 |

点弯曲强度 | ISO 178 | MPa | 90 |

弯曲模量 | ISO 178 | MPa | 2300 |

硬度 | ISO 2039/1 | MPa | 95 |

Taber 耐磨测试,CS-10F,循环 500 次,500 克¶ | ASTM D 1044 | % 雾度 |

|

热性能 | |||

维卡软化温度,B/120 | ISO 306 | ºC | 145 |

热变形温度,0.45 MPa | ISO 75/Be | ºC | 138 |

导热系数 | ASTM C 177 | W/mºC | 0.2 |

线性热膨胀系数 | ASTM D 696 | 1/ºC | 7.00E-05 |

相对热指数 | UL 746B | ºC | 100 |

燃烧性能 | |||

有限氧指数 | ISO 4589 | % | 25 |

光学性能 | |||

透光率 (透明板材) | ASTM D 1003 | % | 84-90 |

光学瑕疵# | DIN52305/AS | % | 通过 |

?? 这些性能指标源自生产该板材的Lexan树脂原料的性能数据。由于板材颜色及厚度的不同,数据有可能在容许的公差范围内波动。如果需要对某些性能提出确认或证明,请联系沙伯创新塑料集团在当地的销售机构。上表中所有的数据都是在23ºC/50%相对湿度条件下至少放置48小时后测得。所有的测试试样都来源于注塑成型样,所有的样品都按照ISO294标准准备。

# 板材样品在3-8mm厚度通过DIN 52305/AS测试要求

¶ Taber耐磨测试采用预加500g载荷的CS-10F胶轮在试样表面旋转500次;然后测量试样表面雾度的增加值。测试结果表明,Lexan Margard MR5E板材的雾度值相对于未经过涂层处理聚碳酸酯板材产品小很多。

平面应用

由于Lexan Margard MR5E具有抗划伤涂层,因而其不能进行冷弯成型处理,只能作为平板应用。

冲击强度

Lexan Margard MR5E具备完美的抗冲击特性,其抗冲击性是玻璃的250倍,亚克力板材的30倍。该款板材的抗冲击性能能够满足大多数的国际标准,规格在4mm及以上的板材产品都能够满足DIN 52290-4的国际标准。

DIN 52290-4

防冲击水平 | 下落高度 | 冲击能量/次 J | 总的冲击能量/水平 J |

A1 | 3500 mm | 141 | 423 |

A2 | 6500 mm | 262 | 786 |

A3 | 9500 mm | 383 | 1149 |

清洗

板材清洗指导意见。不要使用擦洗剂和强碱清洗剂。不要使用橡胶扫帚、刀片或者其它锋利物来刮擦板材。不要在太阳曝晒或者温度升高过程中清洗该款板材。采用Butyl Cellusolve来清洗画笔、记号笔、墨汁或者口红等的痕迹。采用煤油、石脑油或者石油溶剂油来清除标签、胶带等杂物会有很好的效果。在上述操作完成之后,可使用温和肥皂液轻轻的清洗板材,最后换以清水冲洗干净即可。

耐化学腐蚀性

Lexan Margard MR5E板材经过特殊的表面涂层处理,使得它能抵抗很多化学物质的侵蚀作用。采用大量化学物品对该款板材产品进行表面接触测试,结果证明测试前后板材的落镖冲击性能没有发生变化,同时这也说明了这款板材对工业或者很多苛刻工作的环境的适应性。然而,如果该产品将使用在有化学物质接触的环境中的时候,还是建议使用前对这款板材产品进行化学兼容性测试。

防火测试性能

Lexan Margard MR5E根据其不用的厚度和颜色等级对很多国家防火指标都有很好的防火性能;请于当地的销售部门取得联系以获得进一步的信息。

波纹方向(Ripple Orientation)

在一些要求严格的应用上,由于加工工艺及硬化涂敷技术所造成的板材表面细微波纹或起伏,会对板材的使用带来重要的影响。在板材表面保护膜上会有连续带状条纹标明该微波纹方向(Ripple Orientation)。

可用的产品的规格

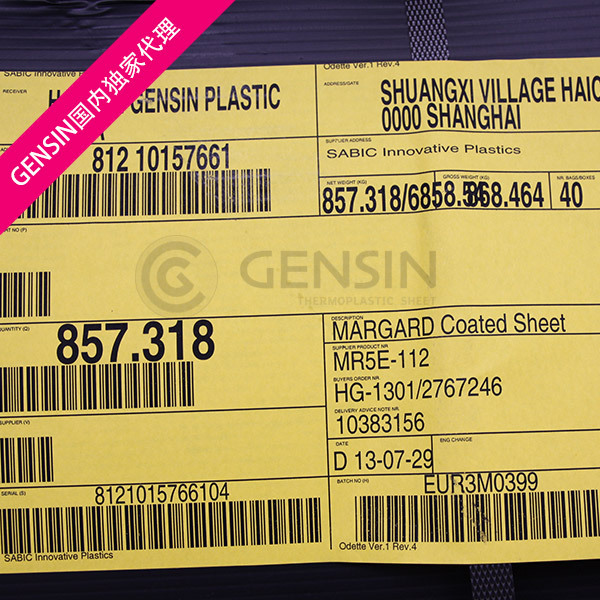

产品代码:MR5E

标准尺寸:2000×3000 mm

厚度:3,4,5,6,8,9.5和12 mm

标准颜色:透明(代码112),铜色(代码5109)

如果进行了提前预约安排,也可以生产上述规格之外的其它规格和颜色的MR5E板材。这些预约安排可能会影响产品销售的价格,担保内容以及使用条件。

特别提示:网上价格一般只作参考,特殊颜色和特殊规格可以为您定制! 欢迎您来电洽淡合作,并真诚期待您莅临我厂实地考察!

| 企业概况 海宁市正兴耐力板有限公司注册资本1680万元人民币,成立于2003年,占地面积18000平米,自建标准厂房10000平米,年产能20000吨,年营业额15000万元人民币,并以每年30%速度递增。拥有员工200余人,其中专业技术人员15名,工程师8人,是集PC板材、PMMA板材、型材及其它板材延伸产品的设计制造、国际贸易为一体的综合性高新科技企业。 营销网络 目前,正兴Gensin在荷兰,印尼,印度,日本,北美等地设有代表处,并在内地的北京,上海,广州,无锡,重庆设有分公司,以确保对全球客户全面可靠的支持和供应。

|

业务电话:400-666-1197

网址:http://www.gensin.com

---------------------------------------英文版---------------------------------------

DESCRIPTION

LEXAN™ MARGARD™ MR5E sheet is a transparent UV and mar resistant glazing material for flat applications only. The intrinsic properties of LEXAN polycarbonate combined with its dual hard coated surface provide: high impact strength and forced entry protection, graffiti resistance, excellent all weather performance, unique ten (10) year warranty against breakage and seven (7) year limited warranty against yellowing, loss of light transmission and coating failure.

Property | Test Method | Units | Value |

Physical | |||

Density | ISO 1183 | g/cm³ | 1.20 |

Water absorption, 50% RH, 23 °C | ISO 62 | % | 0.15 |

Water absorption, saturation, 23°C | ISO 62 | % | 0.35 |

Mechanical | |||

Yield stress 50 mm/min | ISO 527 | MPa | >60 |

Yield strain 50 mm/min | ISO 527 | % | 6 |

Nominal strain at break 50 mm/min | ISO 527 | % | >100 |

Tensile modulus 1 mm/min | ISO 527 | MPa | 2300 |

Flexural strength 2 mm/min | ISO 178 | MPa | 90 |

Flexural modulus 2 mm/min | ISO 178 | MPa | 2300 |

Taber haze - 100 cycles, 500 gram, CS-10F | ASTM D1044 | % | 1 - 3 |

Taber haze - 500 cycles, 500 gram, CS-10F | ASTM D1044 | % | 3 - 8 |

Thermal | |||

Vicat softening temperature, rate B/120 | ISO 306 | °C | 145 |

Temperature of deflection under load (type A), 1.8 MPa, flat | ISO 75-2 | °C | 127 |

Thermal conductivity | ISO 8302 | W/m.°C | 0.2 |

Coefficient of linear thermal expansion, 23-55°C | ISO 11359-2 | 1/°C | 7x10-5 |

Ball pressure test 125 ±2°C | IEC 60695-10-2 | - | Pass |

Electrical | |||

Volume resistivity | IEC 60093 | Ohm.cm | >1015 |

Dielectric strength, in oil, 3.2 mm | IEC 60243-1 | kV/mm | 18 |

Fire Ratings | |||

Electrical | |||

Horizontal burn | UL94 HB | - | 3 - 12 HB |

Transportation | |||

Automotive - horizontal burn | 95/28/EC annex IV | - | 3 - 12 mm pass |

Optical | |||

Light transmission 2 mm | ASTM D1003 | % | 93 |

Light transmission 3 mm | ASTM D1003 | % | 92 |

Light transmission 4 mm | ASTM D1003 | % | 92 |

Light transmission 5 mm | ASTM D1003 | % | 91 |

Light transmission 6 mm | ASTM D1003 | % | 90 |

Light transmission 8 mm | ASTM D1003 | % | 88 |

Light transmission 9.5 mm | ASTM D1003 | % | 87 |

Light transmission 12 mm | ASTM D1003 | % | 85 |

Light transmission 15 mm | ASTM D1003 | % | 82 |

Diopter 2 - 8 mm | DIN52305/AZ | < 0.06 | |

FLAT APPLICATIONS

Due to its mar-resistant coating, LEXAN™ MARGARD™ MR5E sheet cannot be cold-formed. The sheet is intended for flat applications only.

IMPACT STRENGTH

Virtually unbreakable, LEXAN MARGARD MR5E sheet has up to 250 times the impact strength of glass and 30 times that of acrylic. LEXAN sheet offers outstanding impact strength and complies with the majority of international standards. With a thickness of 4 mm and upwards it complies with DIN 52290 part 4.

CLEANING

For cleaning instructions consult guidelines. Do not use abrasive or highly alkaline cleaners, never scrape the sheet with squeegees, razor blades or other sharp instruments. Do not clean LEXAN MARGARD sheet products in hot sun or at elevated temperatures. For removal of paints, marking pen, inks, lipstick etc. use Butyl Cellusolve. To remove labels, stickers etc. the use of kerosene, naphta, or white spirits is generally effective. Afterwards, a warm final wash should be made, using a mild soap solution and ending with a thorough rinsing with cold water.

CHEMICAL RESISTANCE

LEXAN MARGARD MR5E sheet’s unique coating provides immunity

to many chemicals. Surface contact tests on LEXAN MARGARD MR5E

sheet with a wide range of chemicals have proven to have no

effect on impact resistance during falling dart testing, proving the

excellent fit for LEXAN MARGARD for industrial or aggressive

environments. In applications where the product will come into

contact with aggressive chemicals, specific testing of the material

is always advised.

FIRE TEST PERFORMANCE

LEXAN MARGARD MR5E has good fire performance against many

national fire codes dependent on thickness and color; please check with the local sales office for details.

RIPPLE ORIENTATION

For some applications the ripple orientation may play an important role in the optical performance of the sheet. This orientation is marked with a continuous ribbon applied to the sheet masking.

Product Availability

Product Code : MR5E

Standard Size : 2000 x 3000 mm

Thicknesses : 3, 4, 5, 6, 8, 9.5 and 12 mm

Standard Colors : clear (code 112), bronze (code 5109)

For MR5E different colors and dimensions can be made

available by prior arrangement. Such arrangements may affect prices, warranty terms and/or conditions of sale