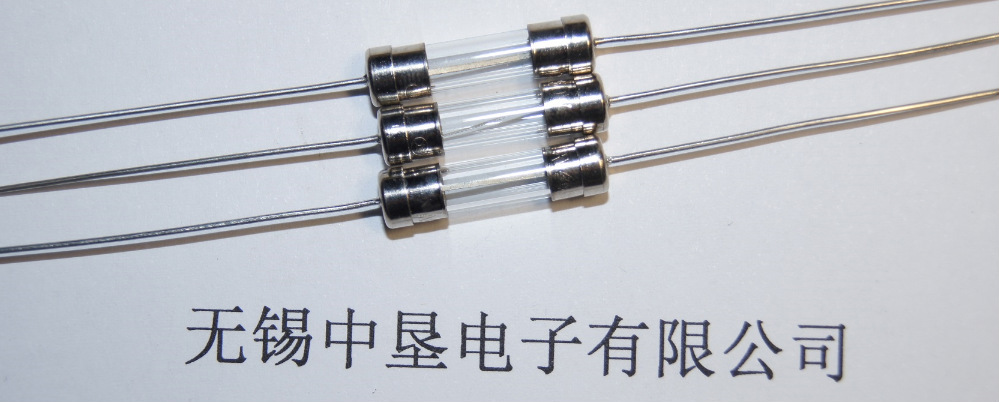

企业集采 3.6 X10 /T2A陶瓷保险丝管

无锡中垦电子有限公司

新区纺城路288号

产品属性

图文详情

品牌推荐

品牌/型号

国产/3.6*10

种类

保险丝管

加工定制

是

温控范围

10(℃)

形状

平头管状

自动复位功能

无

体积

大型

保持电流

10(A)A

型号

3.6*10

最大电流

20(A)

电压特性

高压

熔断速度

TT/特慢速

品牌

国产

用途

机床

最大电压

250(V)V

执行标准

国标

动作温度

20(℃)

属性

1

'

| 中 垦 电 子 有 限 公 司 | |||||||||||||||||||||||||||||||||

| 【产品规格书】 | |||||||||||||||||||||||||||||||||

| ZHONG KEN ELECTRONIC CO.,LTD. | HD:2009年版 | ||||||||||||||||||||||||||||||||

| 玻 管 式 保 险 丝 | |||||||||||||||||||||||||||||||||

| Fuse for Instrumcnt,Power and telephone(Nonindicating) | |||||||||||||||||||||||||||||||||

| 1. 适用范围:本标准适用于保护仪器,各类电器元件,电源供应器和电话机用之玻管式熔断保险丝. | |||||||||||||||||||||||||||||||||

| 1. Available Range:For protccting instrurucnts,all electron or electronal power supplies and | |||||||||||||||||||||||||||||||||

| telephone sets | |||||||||||||||||||||||||||||||||

| 2. 形状及尺寸如下图:(单位:mm) | |||||||||||||||||||||||||||||||||

| 2. Shape & size as following illustrations:(unit:mm) | |||||||||||||||||||||||||||||||||

| 2.1 构造形状如上图:(Structure & Shape as shown in figure abave) | |||||||||||||||||||||||||||||||||

| 3±0.2_____mm*10±1______mm ( ______ inch ________inch ) formally called_______ | |||||||||||||||||||||||||||||||||

| 2.2 额定电压(Rated Voltage): 250V AC | |||||||||||||||||||||||||||||||||

| 2.3 额定电流(Rated Current): T2A AC | |||||||||||||||||||||||||||||||||

| NO | Parr Name 部名 | Material材料 | Size尺寸 | ||||||||||||||||||||||||||||||

| A | Ferrule Cap套盒(铜头) | Capper(nickel plaring)铜(镀镍) | 3.6*3.65±0.2 | ||||||||||||||||||||||||||||||

| B | Tube 筒管 | Glass Tube(transparenl)陶瓷 | 3.0*9.3±0.5 | ||||||||||||||||||||||||||||||

| C | Fuse Solube Eloment可熔体 | Silver Alloy银合金线 | |||||||||||||||||||||||||||||||

| D | Adhesive粘胶 | Resin & Hardening Agent树脂硬剂 | |||||||||||||||||||||||||||||||

| E | Solder焊锡 | Sn锡99.3%Cu0.7%&rosin alcohol flux焊剂 | Φ0.8mm | ||||||||||||||||||||||||||||||

| F | Pig引线 | Capper Plaring Tinqmgk 铜镀锡 | 0.60*30±0.5 | ||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||

| 3. 材料(Material) | |||||||||||||||||||||||||||||||||

| 3.1 陶瓷管本体:陶瓷管清晰. | |||||||||||||||||||||||||||||||||

| 3.1 Glass tube:Transparenr glass in which the fuse is clear and perspectable .Nobreaking or | |||||||||||||||||||||||||||||||||

| deformation. | |||||||||||||||||||||||||||||||||

| page1 of 3 | |||||||||||||||||||||||||||||||||

| 3.2 两端铜盖:须以导电良好之黄铜底材料. | |||||||||||||||||||||||||||||||||

| 3.2 Tow brass and caps:Made of brass of good conductiviry. | |||||||||||||||||||||||||||||||||

| 3.3 铜盖处理:铜盖部分镀镍 | 标示最后若加"S"者表示须镀银 | ||||||||||||||||||||||||||||||||

| 3.3Coating of brass caps plaring the surfacc with nickel If the indicaron is added with "S". | |||||||||||||||||||||||||||||||||

| it needs to be plared with silver. | |||||||||||||||||||||||||||||||||

| 3.4铜盖强度:铜盖和玻管本体间的扭力最小720g/cm. | |||||||||||||||||||||||||||||||||

| 3.4Slrength of brass caps:The minimum tortion beteen brass caps and glass tube is 720g/cm. | |||||||||||||||||||||||||||||||||

| 4 电气特性:(Charactcrristics of Electrical Appliancos) | |||||||||||||||||||||||||||||||||

| 4.1负载容量:额定电流测100%,能继续通电无任何熔化现象. | |||||||||||||||||||||||||||||||||

| 4.1 Loading Capacity :The listed electrical (Included) add 100% for following,add it\'s | |||||||||||||||||||||||||||||||||

| available to let current kurrcnt.Keep on flowing without any melding. | |||||||||||||||||||||||||||||||||

| 4.2温度特性:进行上项测试须1.5小时后继续维持原加之电流,每隔十分钟测试一次,连续测三次,温度不得 | |||||||||||||||||||||||||||||||||

| 升高,若使用热偶式测量方法(Tbermocouple mcthod)则本体温升在70°C以下,若使用温度计测量方法 | |||||||||||||||||||||||||||||||||

| 则在 50°C以下. | |||||||||||||||||||||||||||||||||

| 4.2Temperature:Proceed the prcceding test for 1.5 houres ,Keep testing it with the original | |||||||||||||||||||||||||||||||||

| current every 10 minutes.Continue to test it for 3 times The temperature is not allowed to | |||||||||||||||||||||||||||||||||

| be higher The main temperature is below 70°C by way of Thermocouple Method While it keeps | |||||||||||||||||||||||||||||||||

| below 50°C by way of Thermometer Mcthod. | |||||||||||||||||||||||||||||||||

| 4.3电阻测量:调整保险丝之额定电流达10%时,在保险丝两端使用高阻抗电压表测量降压值,以计算电阻值或 | |||||||||||||||||||||||||||||||||

| 电桥方式测量(额定电流2.5安培含以上者,无须测量电阻值) | |||||||||||||||||||||||||||||||||

| 4.3Resistance Measuring:Adjust the fuse upto listed electrical current 10%,we measure on two | |||||||||||||||||||||||||||||||||

| ends of the fuse with high voltage meter and caculare the resistance value with electrical | |||||||||||||||||||||||||||||||||

| brige way.(If the listed currecct equal or more the 2.5 Amp,it\'s not necessary to measure | |||||||||||||||||||||||||||||||||

| the resistance value) | |||||||||||||||||||||||||||||||||

| page2 of 3 | |||||||||||||||||||||||||||||||||

| ELEARING TIME | |||||||||||||||||||||||||||||||||

| 熔 断 时 限 | |||||||||||||||||||||||||||||||||

| 电流Amper | 1000%Roating | 400%Roating | 275%Roating | 210%Roating | |||||||||||||||||||||||||||||

| 时间Time | Max:300msMin:20ms | Max :3s Min:150ms | Max:10s Min:600ms | Max: 120s Min: | |||||||||||||||||||||||||||||

| 电压Voltege | 250V | 250V | 250V | 250V | |||||||||||||||||||||||||||||

| 5. 机械特性(Mechanical Properties): | |||||||||||||||||||||||||||||||||

| 乃经下述实验证明(Terminal Connections & Lead Solderability) | |||||||||||||||||||||||||||||||||

| 5.1 拉力强度(Terminal Strength) | |||||||||||||||||||||||||||||||||

| 当施加轴向拉力__1.1____磅于两端导线(或套盖)___5___分钟后,无松动或损坏现象发生. | |||||||||||||||||||||||||||||||||

| Lead and/or caps are soldcred(adhcrcd) to with stand axial pulling force of__1.1___pounds | |||||||||||||||||||||||||||||||||

| for___5___mine.without loosening or any harmfulness to firmly arlachment. | |||||||||||||||||||||||||||||||||

| 5.2 回转强度(Torsion Strength) | |||||||||||||||||||||||||||||||||

| ① 固定一端铜头,另一端施加720g/cm 的力左右摇动,铜头不得松动及发生任何本体的损坏. | |||||||||||||||||||||||||||||||||

| After being subjecteed to 720g/cm torsion to one cap while other terminal fixed ,no any | |||||||||||||||||||||||||||||||||

| damage or loosmning resulted. | |||||||||||||||||||||||||||||||||

| ②一端导线弯折90度,本体以原轴旋转360度(5秒),三次不同方向之旋转后,导线或结合处不发生损坏. | |||||||||||||||||||||||||||||||||

| One lead bent through 90°the bady be clamped and rotated through 360°at a rate or(5 sec) | |||||||||||||||||||||||||||||||||

| about the original axis,Vophisical damage to leads or connections resulted after 3 time | |||||||||||||||||||||||||||||||||

| successive-altematero-tations. | |||||||||||||||||||||||||||||||||

| 5.3 弯折强度(Bending Strength): | |||||||||||||||||||||||||||||||||

| 导线经过两次反方向之弯折后(弯折90度同折回原位置之一次弯折)不发生损坏. | |||||||||||||||||||||||||||||||||

| After two bends of Opposite directions(bending through an angle of 90°and back is detined | |||||||||||||||||||||||||||||||||

| as one bond ) of lead ,Nodamage are to be visualized. | |||||||||||||||||||||||||||||||||

| page 3 of 3 | |||||||||||||||||||||||||||||||||