'

LEAD GAGES

The lead gage inspects both internal and external thread leads using contact points that

seat in the threads of a part. Thread lead is the distance between threads, measured on a

plane parallel to the centerline of the threaded part. The pitch of the thread determines the

diameter of the contact points required for taking measurements.

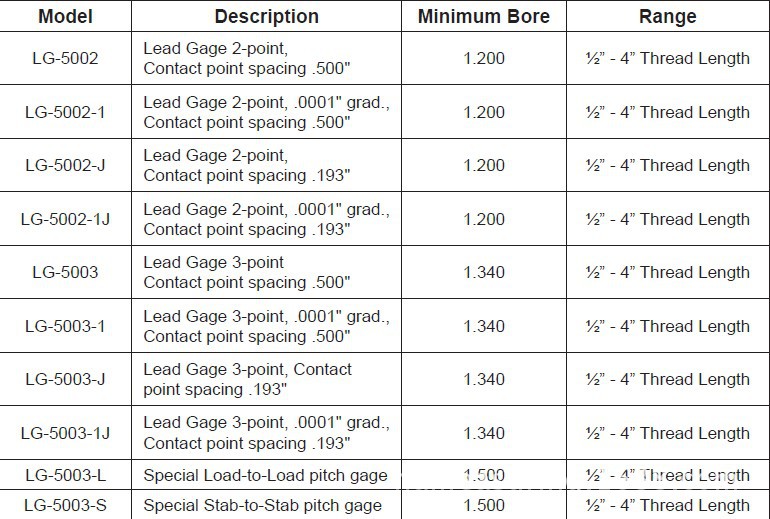

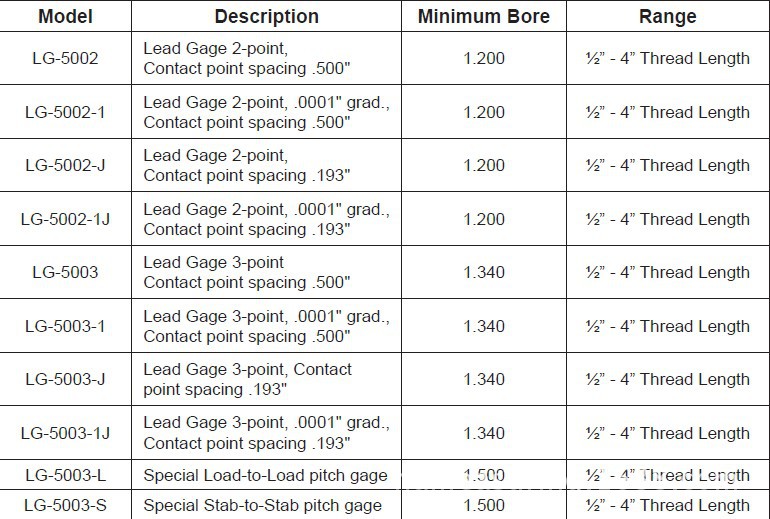

The LG-5002 uses a two-point system to inspect thread lead for ACME, Stub ACME, UN, or

API threads. The two points allow for a sweeping action to obtain the measurement.

The LG-5003 uses the three-point system to inspect thread lead for ACME, Stub ACME, UN

threads, or API threads. Two fixed contact points at the rear of the gage and one moveable

contact point at the front of the gage provide complete stability when taking thread lead

measurements. This unique design does not require sweeping to obtain measurements.

Plus, contact points can be easily changed to allow the gage to be used on a variety of thread

forms.

Before inspecting parts, the lead gage must be preset to a nominal predetermined dimension

using a lead gage setting standard. These setting standards are manufactured according to

ANSI and API specifications. Lead standards are available for ACME, Stub ACME, UN and

API threads. API Spec 7 requires thread lead inspection.

Features

• Uses a three-point system for greater stability when inspecting parts (LG-5003).

• Uses interchangeable contact points to allow inspection on a variety of thread forms.

• Requires presetting using Gagemaker’s lead gage setting standards.

'