泉州卖的免烧压砖机,新型研制免烧红砖,高强度,质量好

YC6-20 双料砌块成型机

一、主要技术参数:

整机功率: 32KW

成型周期: 15-20秒/次

整机重量:7500kg

激振力: 60kn

托板规格: 860x680x20(mm)竹胶板

外型尺寸: 12550x2450x2500(mm)

成型方式:自动布料振压成型

振动加速度: 22g

控制方式: PLC电脑控制全自动

二、主要产品规格及产量

产品类型 | 规格尺寸(长×宽×高) | 块/周期 | 块/时 | 块/天(8小时) | 块/年(300天计) |

空心砖 | 390×190×190 | 6 | 1,080 | 8,640 | 2,592,000 |

多孔砖 | 240×115×90 | 15 | 2,700 | 21,600 | 6,480,000 |

标准砖 | 240×115×53 | 30 | 5,400 | 43,200 | 12,960,000 |

标准砖 | 240×115×50 | 32 | 5,760 | 46,080 | 13,824,000 |

荷兰砖 | 200×100×60 | 21 | 3,780 | 30,240 | 9,072,000 |

注:以上产量表为理论计算值。成型周期、生产量与原材料、产品类型及其它因素有关

三、主要技术特点:

1.控制系统:PLC智能控制。人机界面,控制系统配置安全逻辑控制,生产程序及故障诊断显示功能,并有远程控制系统升级及故障诊断及排除功能,实现无需专业人士,只需简单培训即可掌握操作功能。

2.振动器:采用变频电机多源式同步振动系统,频幅可调,实现低频加料,高频成型的工作原理,以适应不同材料及产品均可获得良好振实效果,振动加速度可达16个级。

3.成型机架:采用高强型钢及特种焊接工艺制造,极其坚固。

4.导向柱:采用超强特种钢材制成,表面镀铬具有良好的抗扭与耐磨能力。

5.布料车布料:独特料车布料旋转强制下料装置,彻底解决湿浆及多孔布料难题。

6.原材料:可充分使用沙、石粉、煤矸石、粉煤灰、钢渣等各种废渣。

7.产品范围:可生产各种彩面(分层布料)及通体地砖、码头连锁砖、植草砖、水利砖、空心砌块、多孔砖、免烧标砖等。

YC6-20 Double-fabric Automatic block making machine

Technical Data:

Vibrate the acceleration | 22g |

Molding cycle | 15-20(s) |

Total power | 32(KW) |

Total weight | 7500kg |

Pallet size | 860*680*20(mm)(Bamboo gum plank) |

Shape size | 12550x2450x2500(mm) |

Model the way | the automatic cloth flaps to press to model |

Control the way | the PLC computer controls full-automatic |

Specification&Capacity of Main Products | ||||

Items | Size(LxWxH) | Pcs./mould | Pcs./hour | Pcs./8hour |

Hollow Block | 390x190x190 | 6 | 1,080 | 8,640 |

Porous Bricks | 240x115x90 | 15 | 2,700 | 21,600 |

Dimension Bricks | 240x115x53 | 30 | 5,400 | 43,200 |

Dimension Bricks | 240x115x50 | 32 | 5,760 | 46,080 |

Holland Block | 200x100x60 | 21 | 3,780 | 30,240 |

Note: the above yield form computes a value for the theories. Modeling the period,volume of production has something to do with original material, product type and other factor.

Main technique characteristics:

1.Control the system: PLC intelligence controls(Japan Brand). Man-machine interface, The control system is installed a safe logic control, the display function of production procedure and trouble-shooting.Remote-control the upgrade of the system,trouble-shooting and elimination function.Don’t need professional.Only need train simplely,people can master the operation function .

2.Vibrate the machine: Adopt variable-frquency motor and many sources synchronous vibration system.The range of frequency is adjustable.Achieve feeding of low-frequency and moulding of the high frequency work principle.To make different material and products get good result of vibration.The vibration acceleration could achieve 16 classes .

3.Moulding frame:Adopt high strong stainless steel and special jointing craft to make.Very fastness..

4.Lead to the pillar:Adopt the super and strong special steel material to make. The surface chromeplate have great ability of ati-distort and wearable.

5.Feeding of Feeding system:Special feeding of feeding system rotate force feeding equipment,absolutely solve the problem of wet slurry and porous feeding .

6.At first material:Can use the sand, stone powder, coal gangue, powder ash from stove, the steel residue,flyash ...etc. various residue

7.Product scope:Can produce various colourful side(Dual-fabric ONLY)and a body a brick, wharf catena brick, plant the grass brick, water conservancybrick, hollow carve the piece, porous brick and exempt-burned brick etc.

成品示例 (Bricks produced by our block machine):

我们来自世界各地的客户 (our clients):

我们的认证:欧盟CE认证,德国TUV认证,ISO9001认证。

(Certifications of CE,ISO9001 and GMC by TUV)

成品(砖块)强度检测:45-50兆帕(通过省质监局检测)

(The compressive strength of block machine reach 40-50 Mpa,it has been proven by authoritative testing institutions)

生产线示意图 (Schematic drawing of block machine steps):

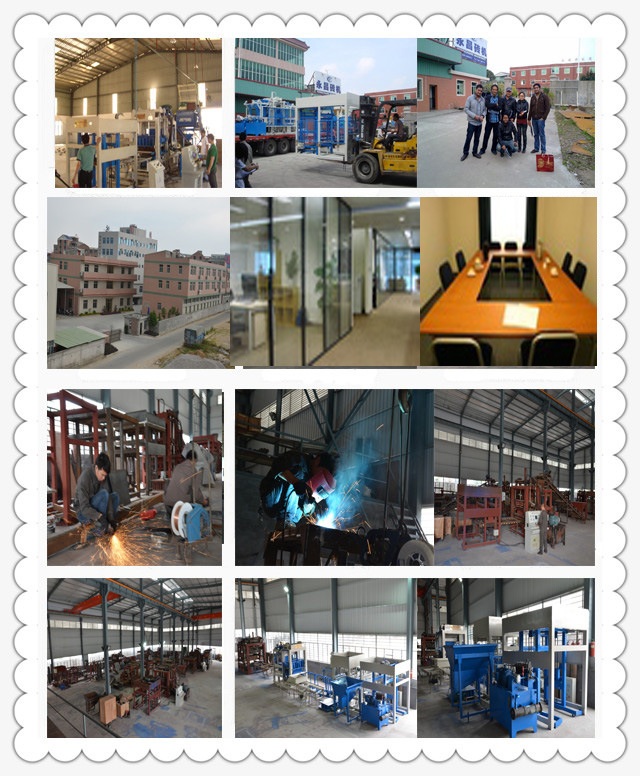

我们公司 (our factory):

联系方式 Contact Ways:

电话 : 0590-86650578

'