'

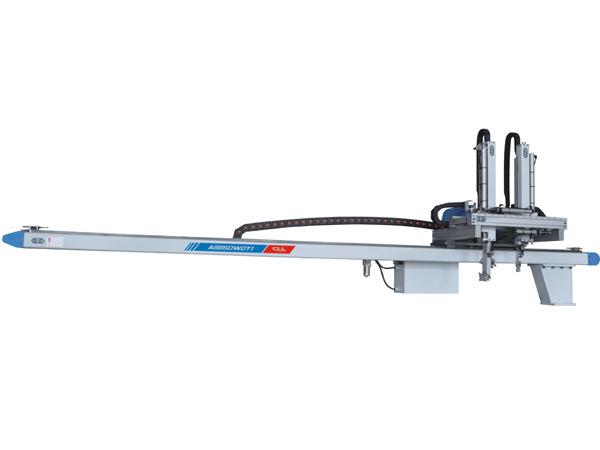

AB 系列纵走式机械手适用于50~450顿的各型卧式射出成型机的成品取出,安装方向与传统式的横走式不同,是将成品与料头取出放置于射出机尾端,可以节省射出机的安装空间。有单截式及双截式;均可增加副臂用于三片模,同时夹成品与料头。上下行程从600~1000mm。安装可节省射出机安装空间30~40%、更充分的利用厂房;并可增加产能(20~30%)降低产品的不良率、保障操作人员的安全性、减少人工、精准的控制生产量、减少浪费。\\

AB series robot arm

is applicable to all types of horizontal injection machine of 50~450T for take-out products. The installation direction is different from traditional beam robot, products and sprues are placed at the end of IMM. It has single stage and telescopic type; It can be added a sub-arm for 3-plates mold to grip products and sprue at the same time, vertical stroke: 600-1000mm. Install AB SERIES robot can save 30~40% room to allow better utilization of production space; Furthermore, the productivity will be increased 20~30%, reduce defective rate, ensure safety of operators, reduce manpower and accurately control the output to reduce waste.

■采用高性能AC伺服马达驱动,可取出成品深度大之产品,取出产品多样化;超高速的取出时间大幅提升生产的效率。

■高刚性3D结构设计,结构稳定震动小耐久寿命长。

■使用高精度高速专用的直线滑轨,耐磨损、耐热、寿命长不变形。

■手臂结构采用高刚性铝挤型梁,品质轻、高刚性,配合皮带倍速机构保证取出时间。

■T型齿型钢丝PU皮带传动,稳定性佳,定位精确重现性达 0.15mm。

■Driven by high performance AC servo motor, it can take-out variety depth products. To take-out at super high-speed, greatly increased output efficiency.

■High rigidity 3D structure design, stable construction, low vibration, longwearing and long-life.

■Using special high precision and high speed linear slide rail, wearproof, heatproof, long-life and not deformed.

■Arm with high rigidity aluminum beam, light mass, high rigidity, cooperated with double-speed belt construction ensured the take-out time.

■T type steel wire PU belt driven, good stability, precision position at 0.15mm.

'