优质电动葫芦双梁起重机5-50T,山东名企天力

山东天力重工集团有限公司

中国 泰安

产品属性

图文详情

品牌推荐

品牌

天特

型号

MH

构造

双梁

取物装置

吊钩

使用场合

防爆桥式起重机

额定起重量

50t

总起重量

50t

有效起重量

50t

起升范围

9m

2T

A5

我公司采用世界先进的欧式起重机制造工艺,质量稳定,产品质量优于国家标准。

山东天力重工集团有限公司设计、制造、安装的起重机执行以下中国及企业标准:

GB/T 3811-2008 Design specifications起重机设计规范

GB/T 5972-2006 Crane wire rope inspection and scrap codes of practice起重机用钢丝绳检验检验和报废实用规范

GB/T 6067-1985 Crane safety specification起重机安全规程

GB/T 10183-2005 Girder crane, gantry crane produce and rail installation tolerance桥式和门式起重机 制造及轨道安装公差

JB/T 3695-2008 Electric hoist bridge crane电动葫芦桥式起重机

JB/T 9008-2004 Wire rope electric hoist钢丝绳电动葫芦

JB/T 10559-2006 Crane nondestructive testing and weld joint ultrasonic inspection and measurement起重机械无损检测 钢焊缝超声检测

Bidding documents technical specification本投标文件制订的技术要求

2.21B11B11B11B11B11B11BEx-work inspection and site testing list explanation出厂检验及现场试验项目说明

欧式起重机的标准检查和测试,满足绝大部分客户的需要,包括如下内容:

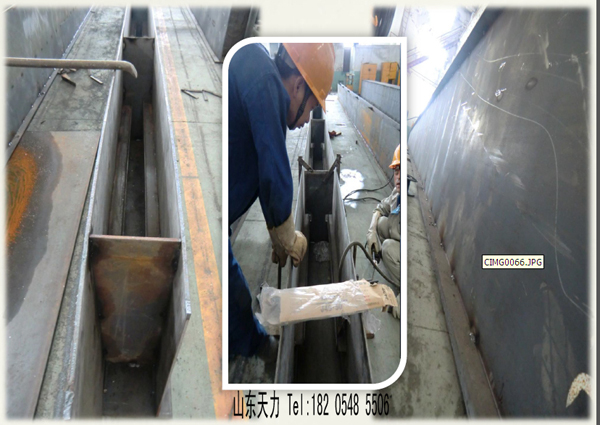

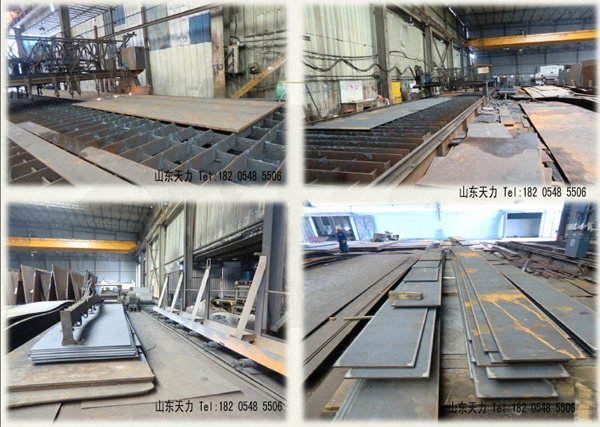

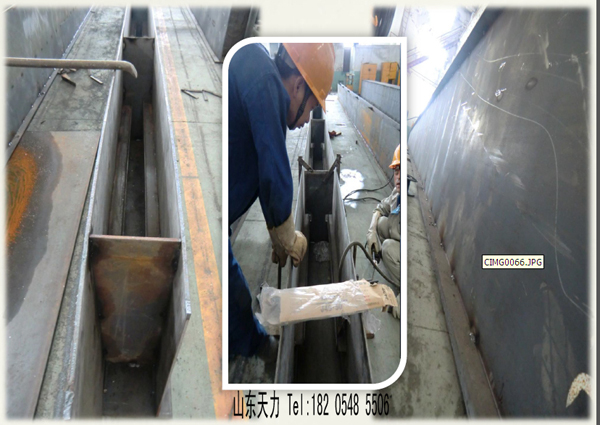

钢结构Steel structure

-所有原材料带出厂合格证明。 All the raw material have the outgoing qualification

-所有焊工具备资质证书。All welder have the license certificates

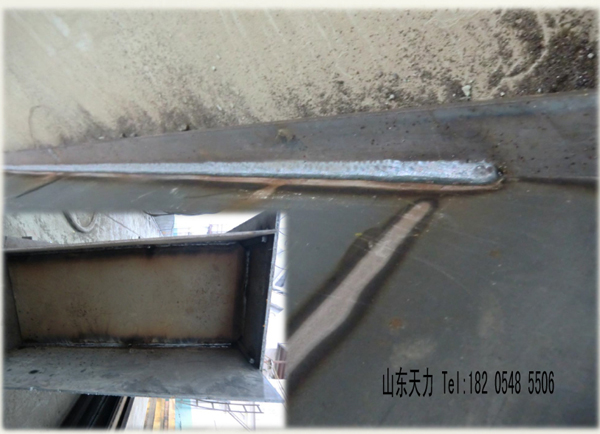

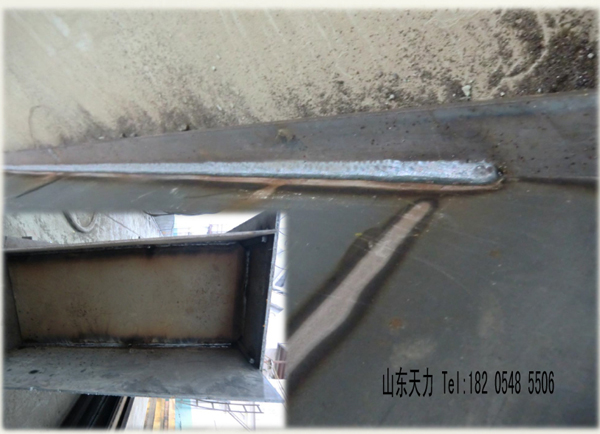

-主要对接焊缝都经过无损检测。Main weld joint passed the nondestructive examination.

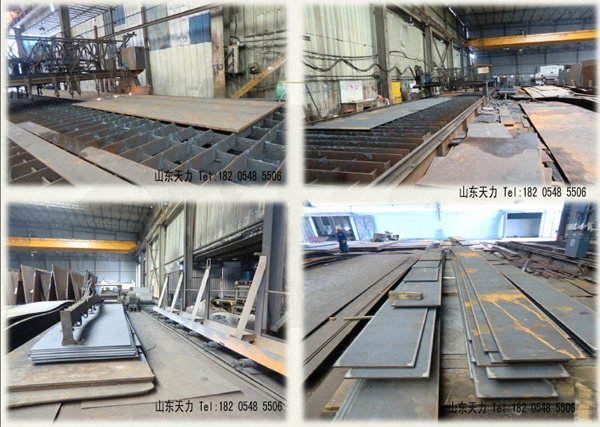

另外:1起重机结构制作按欧式起重机标准制作,主梁组装在专用胎架上进行,保证起重机的拱度符合国家标准。

2.2.2焊接采用埋弧自动焊接,并且采用两台焊机同时焊接,尽量避免焊接变形。

2.2.3起重机组装,在在专用胎架上进行,保证起重机的组装尺寸符合标准。预装桥架确保正确的跨距和定位。Ensure preinstallation girder according to right span and orientation.

-用光学测量仪检测车轮定位保证精度。Ensure the wheel positioning accuracy by using optical coordinate measuring apparatus

-通过工厂的空载试验来检查整车的功能并调整好各速度和关键尺寸。Inspection whole crane performance a

机械部分Mechanical part

端梁采用矩形管,外形美观平整。电机采用台湾秋田产品,质量稳定。

4. Mechanical part机械部分

4.1 Hoist起升机构

Motor, fan, reducer, brake, drum integral design, compact form电机、风扇、减速机、制动器、卷筒一体化设计,结构紧凑

起升电机Hoist motor

鼠笼式、双绕组6:1变极双速电机Squirrel-cage, duplex winding 6:1 inverter double-speed motor

防护等级IP55 、F级绝缘Protection IP55, F isolation

接电持续率60%ED

内置热敏电阻过热保护。Thermal resistor inside for overheat protection

全密封内置于卷筒Hermetically in drum

电机壳由铝管冲压成型Motor casing impact molding by aluminium pipe

科尼公司设计、制造KONECRANE company design and produce

● 减速箱Reducer

完全密封紧凑型齿轮箱Hermetically compact gear case

齿轮材料为铬钼合金、抗磨轴承Gear material is molybdenumchrome and antifriction bearing

CNC自动齿轮加工中心生产,硬齿面(HRC60)、经过研磨处理Produced by CNC auto gear machining center, JRTR(HRC60), treated by smat.

半油脂润滑、免维护Semi-grease lubrication, maintenance free.

科尼公司设计、制造KONECRANE company design and produce

制动器Brake

电磁盘式制动器,当刹车片厚度不够时报警Electromagnetic disk brake, warning as brake disk inadequate thickness,

刹车片寿命:正常使用不低于100万次,紧急制动不低于500次Brake disk lifetime: normal use more than 1 million times, emergency brake more than 500 times.

常闭式设计,在断电时起升机构,出于制动状态确保安全Normally closed design, keep hoist brake status for safe as blackout.

防尘、无石棉磨擦片Dustproof, non-asbestos brake disk

摩擦接触面积达,制动力矩可调,Large friction contact area, braking torque adjustable

散热性能好Low heat generation

科尼公司设计制造KONECRANE company design and produce

限位开关Limit switch

凸轮旋转式限位开关Rotary cam limit switch

4个完全可调的上下限位4 up-down adjustable limit switch

精确相序控制Precise phase control

先减速后停止First slowdown then stop

减速操作提高制动器寿命及安全性Slowdown prolong brake lifetime and safety function

科尼公司设计制造KONECRANE company design and produce

卷筒Drum

特大卷筒直径Big diameter drum

延长钢丝绳寿命,重物放置偏移小Prolong wire rope lifetime, small displacement put down

高强度镀锌钢丝绳High tensile galvanized steel wire rope

导绳器Rope guider

对钢丝绳磨损小,寿命长,韧性和弹性好Reducing the rope wear, long lifetime, well toughness and spring

可靠性高,方便拆卸High reliability, easy disassembly

即使吊钩被降至地面也能保持钢丝绳的张紧Keep wire rope tension even if the hook down to floor

吊钩Hook

吊钩组有大直径的球墨铸铁制成的 滑轮及吊钩组成Hook block made by nodular cast iron, including block and hook

采用抗磨滚子轴承Use roller bearing combat abrasion

吊钩可以360°旋转Hook can rotate 360°

配置弹簧压紧的安全扣Equiped with spring hook

吊钩锻件为调质钢 34CrMoV,依据标准

DINI7200 Hook forgings 34CrMoV, according to DINI7200

4.2 大小车行走机构Trolley and Traveling motor

运行电机Traveling motor

鼠笼式变频电机或软启动电机Squirrel-cage inverter 2-speed motor

变频控制运行平稳,无爬行,启动,变速时减少重物晃动Smooth running, non-crawl, steady aim by inverter control

防护等级IP55、F级绝缘Protection IP55, F isolation

电机接电持续率40%ED

全密封、风冷式Hermetically, air-cooled type

内置热敏电阻过热保护Motor casing impact molding by aluminium pipe

欧式起重机行走减速箱Traveling reducer box

三合一结构Triad structure

齿轮材料为铬钼合金、抗磨轴承Gear material is molybdenumchrome and TTTantifriction bearing

CNC自动齿轮加工中心生产,硬齿面(HRC60)经过研磨处理Produced by CNC auto gear machining center, JRTR(HRC60), treated by smat.

半油脂润滑、免维护Semi-grease lubrication, maintenance free.

UU欧式起重机制动器Brake

电磁盘式制动器Normally closed design, keep hoist brake status for safe as blackout.

防尘,无石棉摩擦片Dustproof, non-asbestos brake disk

欧式起重机车轮Wheel

欧式起重机车轮材料为球磨铸铁(硬度200...300 BNH) Wheel material is TTTnodular cast iron (Rigidity 200…300 BNH)

欧式起重机限位开关Limit switch

大车两档式(减速+停止)限位开关Traveling jumper select(slowdown stop) limit switch

小车一档式(停止)限位开关Trolley one stop limit switch

减速操作提高制动器寿命及安全性Slowdown control prolong brake lifetime and safety

在行走方向的两端各装有触发档杆Equip with trigger level at two end of traveling

具备自动复位功能Auto reset function

限位开关有坚固的金属外壳,保护等级IP55 Limit switch have auto-firm metal shell with IP55 protection

4.3 整机结构Whole product structure

极限尺寸小,增加有效工作面积

Small extreme dimension,

降低厂房高度,节省建筑成本

add available working area,

体积小、自重轻lower factory height,

save construction cost, small volume, light self-weight

5. Factory tests and quality control测试

桥式起重机的工厂和质量控制

天力公司的标准检查和测试,满足绝大部分客户的需要。

The standard in-house inspection and testing plan meets most requirements. It includes following items:

如有要求,天力起重机可安排第三方进行检测,确保设备按技术要求制造。但要收取此部分检测的费用

如有要求,山东天力重工集团有限公司也可安排客户指定的检测和试验,这类试验及详细的试验程序必须在试验前经双方认可。但要收取此部分检测的费用。

我们很欢迎客户在发货前来工厂检测

钢结构Steel Construction

主要原材料带出厂合格证明All purchased load-bearing material, such as girder plates are supplied with quality certificates.

所有焊工具资质证书All welders and weld procedures are qualified.

主焊缝经过无损检测The welds are inspected.

机械部分Machinery

吊钩有认可证书Hooks forgings are certified.

钢丝绳带合格证书Ropes have manufacturer’s certificates.

齿轮经过无载测试和硬度检测Gears have no-load running test including hardness and backlash measurements.

电机测试包括电阻、绝缘电阻、高压、短路测量和空载试验Motor testing includes resistance, insulation resistance, high voltage and short circuit measurements and a no-load running test.

安装Assembly

预装桥架确保正确的跨距和定位Ready assembled crane is measured to verify correct span and alignment.

用光学测量仪检测车轮保证精度Measuring devices secure wheel alignment. Crane will be completely assembled at our workshop and run without load to check the function of the crane and to verify the dimensions.

测试Testing

通过工厂的空载试验来检查整车的功能并调整好各速度和钩距

Carry out inspections and adjust every speed and space according to no-load testing.

6.技术培训training

起重机安装验收合格后,本公司售后部门会对贵公司提供操作人员培训。

Acceptance crane installation, the Company will you provide after-sales sector operator training.

7.卖方承担起重机的包装运输、在买方卸货、安装调试及报检验收手续工作和相关费用。

The seller to bear the crane packaging, transportation, unloading at the buyer, installation and inspection and acceptance procedures and associated costs.

9.卖方在买方工厂对起重机安装调试完毕后,与买方共同进行终验收。按国家起重机验收标准进行静负荷、动负荷试验,并检验主梁和小车轨道变形量,做记录归档。经国家有权机关验收合格后,买卖双方签署验收报告完成终验TTTAfter installation of the crane,together with the cuntomer to do the final acceptance according to the national standard. After acceptance by the national authorities, the inspection reports signed by both parties to complete the final examination.

10.SERVICE / MAINTENANCE服务和维修

10.1Quality Promise质量保证承诺

Shandong Tianli Heavy Industry Group Co., Ltd always insists on the approach “quality first, reputation first, take the road that is quality and efficiency unswervingly ", and make the following commitments to customers who ordered our cranes and related products:

我们山东天力重工集团有限公司始终坚持“重质量、重信誉、坚定不移走质量效益型道路”的方针,对订购我公司起重机及相关产品的用户作如下的承诺:

10.1.1

山东天力重工集团有限公司设计、制造、安装的起重机执行以下中国及企业标准:

GB/T 3811-2008 Design specifications起重机设计规范

GB/T 5972-2006 Crane wire rope inspection and scrap codes of practice起重机用钢丝绳检验检验和报废实用规范

GB/T 6067-1985 Crane safety specification起重机安全规程

GB/T 10183-2005 Girder crane, gantry crane produce and rail installation tolerance桥式和门式起重机 制造及轨道安装公差

JB/T 3695-2008 Electric hoist bridge crane电动葫芦桥式起重机

JB/T 9008-2004 Wire rope electric hoist钢丝绳电动葫芦

JB/T 10559-2006 Crane nondestructive testing and weld joint ultrasonic inspection and measurement起重机械无损检测 钢焊缝超声检测

Bidding documents technical specification本投标文件制订的技术要求

2.21B11B11B11B11B11B11BEx-work inspection and site testing list explanation出厂检验及现场试验项目说明

欧式起重机的标准检查和测试,满足绝大部分客户的需要,包括如下内容:

钢结构Steel structure

-所有原材料带出厂合格证明。 All the raw material have the outgoing qualification

-所有焊工具备资质证书。All welder have the license certificates

-主要对接焊缝都经过无损检测。Main weld joint passed the nondestructive examination.

另外:1起重机结构制作按欧式起重机标准制作,主梁组装在专用胎架上进行,保证起重机的拱度符合国家标准。

2.2.2焊接采用埋弧自动焊接,并且采用两台焊机同时焊接,尽量避免焊接变形。

2.2.3起重机组装,在在专用胎架上进行,保证起重机的组装尺寸符合标准。预装桥架确保正确的跨距和定位。Ensure preinstallation girder according to right span and orientation.

-用光学测量仪检测车轮定位保证精度。Ensure the wheel positioning accuracy by using optical coordinate measuring apparatus

-通过工厂的空载试验来检查整车的功能并调整好各速度和关键尺寸。Inspection whole crane performance a

机械部分Mechanical part

端梁采用矩形管,外形美观平整。电机采用台湾秋田产品,质量稳定。

4. Mechanical part机械部分

4.1 Hoist起升机构

Motor, fan, reducer, brake, drum integral design, compact form电机、风扇、减速机、制动器、卷筒一体化设计,结构紧凑

起升电机Hoist motor

鼠笼式、双绕组6:1变极双速电机Squirrel-cage, duplex winding 6:1 inverter double-speed motor

防护等级IP55 、F级绝缘Protection IP55, F isolation

接电持续率60%ED

内置热敏电阻过热保护。Thermal resistor inside for overheat protection

全密封内置于卷筒Hermetically in drum

电机壳由铝管冲压成型Motor casing impact molding by aluminium pipe

科尼公司设计、制造KONECRANE company design and produce

● 减速箱Reducer

完全密封紧凑型齿轮箱Hermetically compact gear case

齿轮材料为铬钼合金、抗磨轴承Gear material is molybdenumchrome and antifriction bearing

CNC自动齿轮加工中心生产,硬齿面(HRC60)、经过研磨处理Produced by CNC auto gear machining center, JRTR(HRC60), treated by smat.

半油脂润滑、免维护Semi-grease lubrication, maintenance free.

科尼公司设计、制造KONECRANE company design and produce

制动器Brake

电磁盘式制动器,当刹车片厚度不够时报警Electromagnetic disk brake, warning as brake disk inadequate thickness,

刹车片寿命:正常使用不低于100万次,紧急制动不低于500次Brake disk lifetime: normal use more than 1 million times, emergency brake more than 500 times.

常闭式设计,在断电时起升机构,出于制动状态确保安全Normally closed design, keep hoist brake status for safe as blackout.

防尘、无石棉磨擦片Dustproof, non-asbestos brake disk

摩擦接触面积达,制动力矩可调,Large friction contact area, braking torque adjustable

散热性能好Low heat generation

科尼公司设计制造KONECRANE company design and produce

限位开关Limit switch

凸轮旋转式限位开关Rotary cam limit switch

4个完全可调的上下限位4 up-down adjustable limit switch

精确相序控制Precise phase control

先减速后停止First slowdown then stop

减速操作提高制动器寿命及安全性Slowdown prolong brake lifetime and safety function

科尼公司设计制造KONECRANE company design and produce

卷筒Drum

特大卷筒直径Big diameter drum

延长钢丝绳寿命,重物放置偏移小Prolong wire rope lifetime, small displacement put down

高强度镀锌钢丝绳High tensile galvanized steel wire rope

导绳器Rope guider

对钢丝绳磨损小,寿命长,韧性和弹性好Reducing the rope wear, long lifetime, well toughness and spring

可靠性高,方便拆卸High reliability, easy disassembly

即使吊钩被降至地面也能保持钢丝绳的张紧Keep wire rope tension even if the hook down to floor

吊钩Hook

吊钩组有大直径的球墨铸铁制成的 滑轮及吊钩组成Hook block made by nodular cast iron, including block and hook

采用抗磨滚子轴承Use roller bearing combat abrasion

吊钩可以360°旋转Hook can rotate 360°

配置弹簧压紧的安全扣Equiped with spring hook

吊钩锻件为调质钢 34CrMoV,依据标准

DINI7200 Hook forgings 34CrMoV, according to DINI7200

4.2 大小车行走机构Trolley and Traveling motor

运行电机Traveling motor

鼠笼式变频电机或软启动电机Squirrel-cage inverter 2-speed motor

变频控制运行平稳,无爬行,启动,变速时减少重物晃动Smooth running, non-crawl, steady aim by inverter control

防护等级IP55、F级绝缘Protection IP55, F isolation

电机接电持续率40%ED

全密封、风冷式Hermetically, air-cooled type

内置热敏电阻过热保护Motor casing impact molding by aluminium pipe

欧式起重机行走减速箱Traveling reducer box

三合一结构Triad structure

齿轮材料为铬钼合金、抗磨轴承Gear material is molybdenumchrome and TTTantifriction bearing

CNC自动齿轮加工中心生产,硬齿面(HRC60)经过研磨处理Produced by CNC auto gear machining center, JRTR(HRC60), treated by smat.

半油脂润滑、免维护Semi-grease lubrication, maintenance free.

UU欧式起重机制动器Brake

电磁盘式制动器Normally closed design, keep hoist brake status for safe as blackout.

防尘,无石棉摩擦片Dustproof, non-asbestos brake disk

欧式起重机车轮Wheel

欧式起重机车轮材料为球磨铸铁(硬度200...300 BNH) Wheel material is TTTnodular cast iron (Rigidity 200…300 BNH)

欧式起重机限位开关Limit switch

大车两档式(减速+停止)限位开关Traveling jumper select(slowdown stop) limit switch

小车一档式(停止)限位开关Trolley one stop limit switch

减速操作提高制动器寿命及安全性Slowdown control prolong brake lifetime and safety

在行走方向的两端各装有触发档杆Equip with trigger level at two end of traveling

具备自动复位功能Auto reset function

限位开关有坚固的金属外壳,保护等级IP55 Limit switch have auto-firm metal shell with IP55 protection

4.3 整机结构Whole product structure

极限尺寸小,增加有效工作面积

Small extreme dimension,

降低厂房高度,节省建筑成本

add available working area,

体积小、自重轻lower factory height,

save construction cost, small volume, light self-weight

5. Factory tests and quality control测试

桥式起重机的工厂和质量控制

天力公司的标准检查和测试,满足绝大部分客户的需要。

The standard in-house inspection and testing plan meets most requirements. It includes following items:

如有要求,天力起重机可安排第三方进行检测,确保设备按技术要求制造。但要收取此部分检测的费用

如有要求,山东天力重工集团有限公司也可安排客户指定的检测和试验,这类试验及详细的试验程序必须在试验前经双方认可。但要收取此部分检测的费用。

我们很欢迎客户在发货前来工厂检测

钢结构Steel Construction

主要原材料带出厂合格证明All purchased load-bearing material, such as girder plates are supplied with quality certificates.

所有焊工具资质证书All welders and weld procedures are qualified.

主焊缝经过无损检测The welds are inspected.

机械部分Machinery

吊钩有认可证书Hooks forgings are certified.

钢丝绳带合格证书Ropes have manufacturer’s certificates.

齿轮经过无载测试和硬度检测Gears have no-load running test including hardness and backlash measurements.

电机测试包括电阻、绝缘电阻、高压、短路测量和空载试验Motor testing includes resistance, insulation resistance, high voltage and short circuit measurements and a no-load running test.

安装Assembly

预装桥架确保正确的跨距和定位Ready assembled crane is measured to verify correct span and alignment.

用光学测量仪检测车轮保证精度Measuring devices secure wheel alignment. Crane will be completely assembled at our workshop and run without load to check the function of the crane and to verify the dimensions.

测试Testing

通过工厂的空载试验来检查整车的功能并调整好各速度和钩距

Carry out inspections and adjust every speed and space according to no-load testing.

6.技术培训training

起重机安装验收合格后,本公司售后部门会对贵公司提供操作人员培训。

Acceptance crane installation, the Company will you provide after-sales sector operator training.

7.卖方承担起重机的包装运输、在买方卸货、安装调试及报检验收手续工作和相关费用。

The seller to bear the crane packaging, transportation, unloading at the buyer, installation and inspection and acceptance procedures and associated costs.

9.卖方在买方工厂对起重机安装调试完毕后,与买方共同进行终验收。按国家起重机验收标准进行静负荷、动负荷试验,并检验主梁和小车轨道变形量,做记录归档。经国家有权机关验收合格后,买卖双方签署验收报告完成终验TTTAfter installation of the crane,together with the cuntomer to do the final acceptance according to the national standard. After acceptance by the national authorities, the inspection reports signed by both parties to complete the final examination.

10.SERVICE / MAINTENANCE服务和维修

10.1Quality Promise质量保证承诺

Shandong Tianli Heavy Industry Group Co., Ltd always insists on the approach “quality first, reputation first, take the road that is quality and efficiency unswervingly ", and make the following commitments to customers who ordered our cranes and related products:

我们山东天力重工集团有限公司始终坚持“重质量、重信誉、坚定不移走质量效益型道路”的方针,对订购我公司起重机及相关产品的用户作如下的承诺:

10.1.1