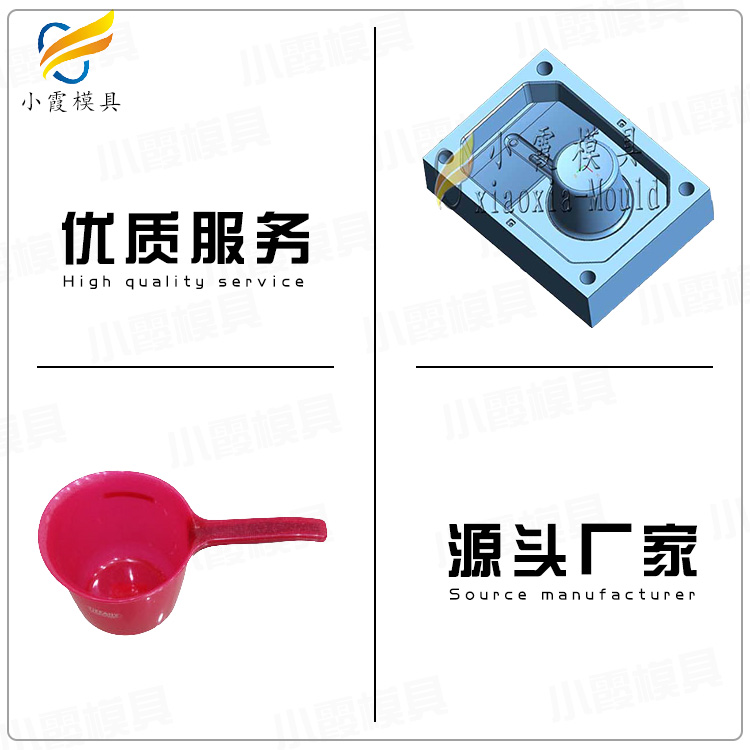

水勺模具 注塑加工接单平台 勺子注塑模具有限公司

台州市黄岩小霞模具有限公司

中国 台州

产品属性

图文详情

品牌推荐

品牌

小霞模具

型号

勺子注塑模具有限公司

成型工艺

注射模

工序组合类型

复合模

适用行业

多种适用

适用范围

多种适用

溢料

半溢式压缩模

浇注系统

热流道模

模具分型面数目

三个

型腔数目

多型腔

模具安装方式

半固定式

质量体系

ISO9001

加工定制

加工定制

主要加工设备

数控铣床,精雕,电脉冲,线切割,钻床,磨床

加工设备数量

36

加工能力

水勺模具

模具寿命

水勺模具公司

模具材质

P20,718,718H,2738,2316,S136,NAK80等等多种材料选择

外形尺寸

水勺模具开模mm

重量

勺子注塑模具有限公司kg

水勺模具

勺子注塑模具有限公司

水勺模具公司

勺子注塑模具有限公司

水勺模具开模

勺子注塑模具有限公司