Kit for the electric control of a fluid level for HCK. and HCK-GL column level indicators

套件为电动控制的流体水平HCK 。和HCK -GL列一级指标

Technical information

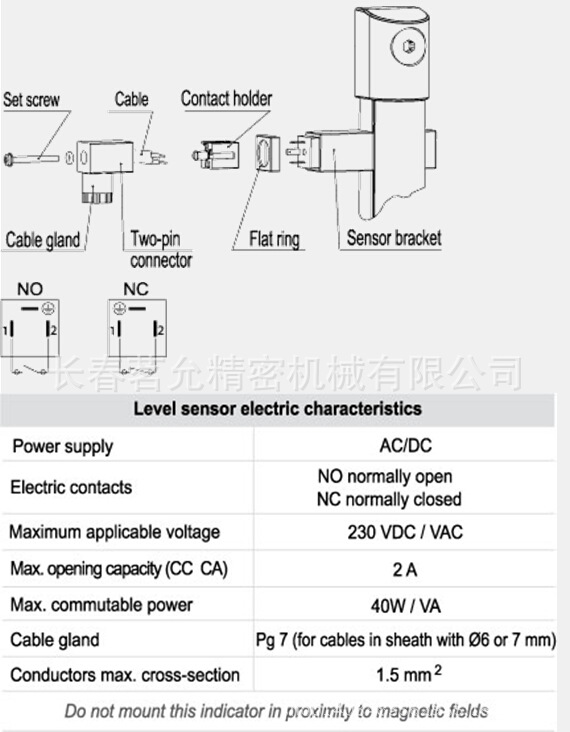

Sensor holder bracket

In polyamide based (PA) technopolymer, black colour,

watertight, with a built-in relay (reed) with two conductors wired to the two-pin connector. It can be moved along the axis of the indicator and secured in the preferred position with the appropriate screw (set screw) in technopolymer.

Electric sensor

- NO: the electric circuit closes on reaching the preset level.

- NC: the electric circuit opens on reaching the preset level.

Connector

With built-in cable gland and contact holders. Properly set, it offers an effective product protection against water sprays ( IP 65 protection class ording to IEC 529 table) that can be increased during installation with the necessary adjustments. NBR synthetic rubber packing rings.

Float

Polypropylene based (PP) technopolymer, black colour, with a built-in ic element to activate the electric contact when the float reaches the trigger threshold.

The trigger threshold is determined by the user, by positioning the sensor holder along the axis of the indicator.

Spacers

In polyamide based (PA) technopolymer. Essential in cases where the reservoir is made out of ic material in order to prevent the interaction between the and the metal mass of the reservoir.

Kit

The kit includes one or two sensor holder brackets, a float, 4 O-rings (2 FKM for HCK-GL and 2 NBR for HCK) and two spacers.

It is possible to apply more than one kit to get the electric control of different levels, consistently with the height of the transparent column.

Standard executions

- SLCK-NO: with electric contact normally open.

- SLCK-NC: with electric contact normally closed.

- SLCK-NO-NC: with one electric contact normally open and one electric contact normally closed.

- SLCK-NC-NC: with two electric contacts normally closed. - SLCK-NO-NO: with two electric contacts normally open.

Maximum working temperature

80°C (with oil).

Features and performances

With the application of the SLCK kit, HCK. and HCK-GL column level indicators provide an electric signal when the fluid level reaches the level of preset intervention, besides the visual control of the level. The electric control of the level can be applied on all versions of HCK. from the version with 127 mm hole centre distance while always maintaining the visibility of fluid level even from side positions.

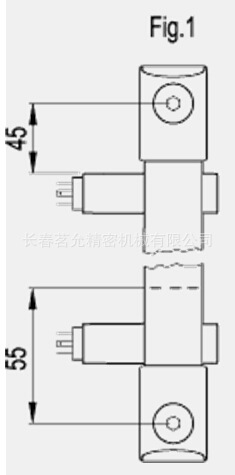

In the highest position, the sensor holder must be positioned at least 45 mm below the axis of the high screw (Fig.1), so that the switching takes place correctly.

In the lowest position, the fluid level which determines the switching of the electric circuit is of about 55 mm above the axis of the low screw of fluid supply (data referring to mineral oil type CB68, ording to ISO 3498, temperature 23°C) (Fig. 1).

The sensor holder is arranged to be installed to the left with respect to the axis of the indicator. However, if required it can also be mounted on the right. The connector can be rotated by 90° in four positions when wiring.

For a correct assembly see Warnings .

Kit assembly instructions

- Remove the assembly end of the indicator (Fig. 2).

- Insert the float with the word "up" to the top (Fig. 3).

- Insert the sensor holder bracket and relocate the assembly end in place (Fig. 4).

- Clamp the bracket with the set screw to the desired position (Fig. 5).

- Install the indicator on the reservoir using the spacers included in the supply (necessary in case of reservoir made out of ic material in order to avoid interaction between the and the metal mass (Fig.6).

- Assemble the two-pin connector (Fig. 7).

Two-pin connectors assembly instructions

1. Remove the connector from the sensor holder bracket by unscrewing the axial set screw, take off the contact holder and unscrew the cable gland as required.

2. Slip on the cable into the connector and connect the wires to the terminals of the contact holder.

3. Assemble by pressing the contact holder into the connector (the contact holder can be rotated by 90° in four positions to have a different orientation of the connector).

4. Screw again the connector to the sensor holder by means of the axial set screw and then tighten the cable gland.