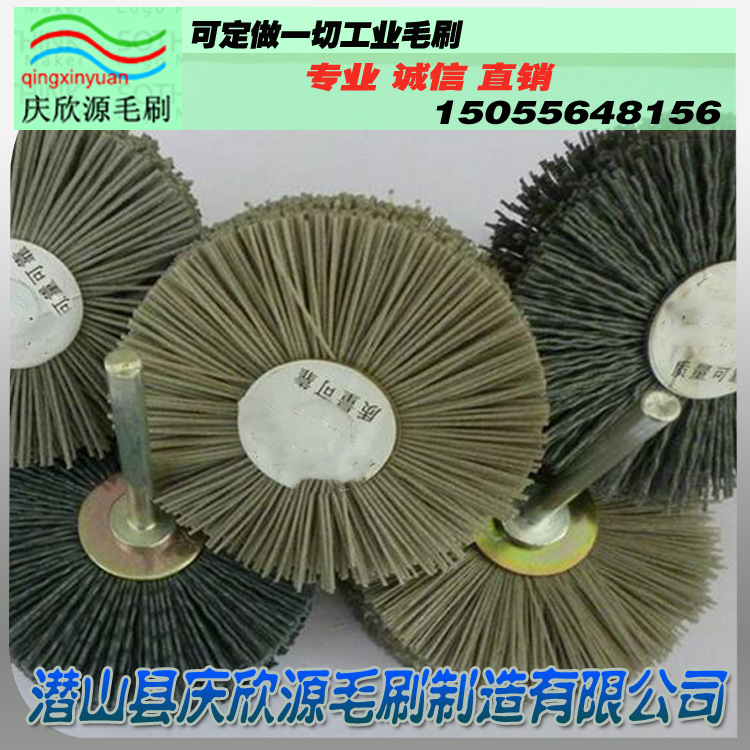

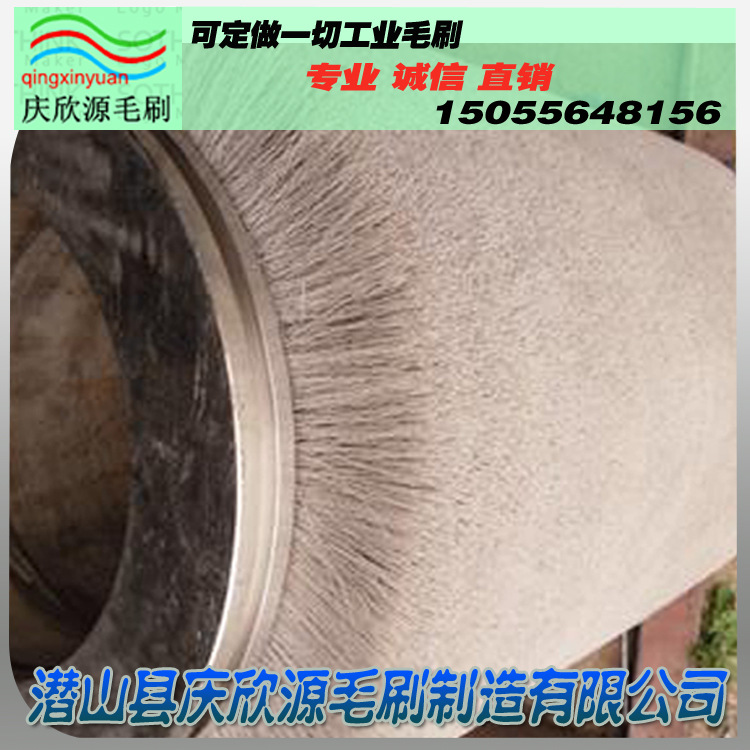

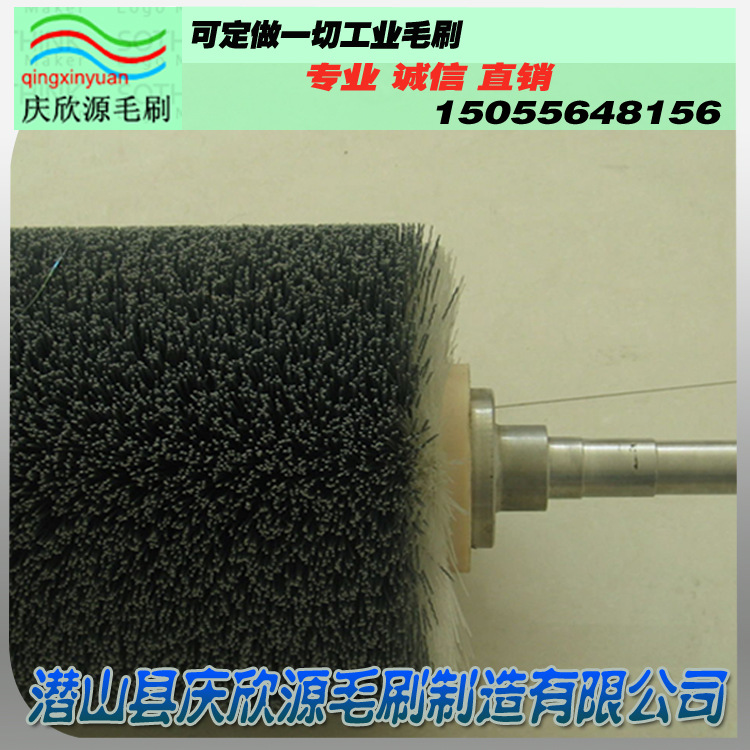

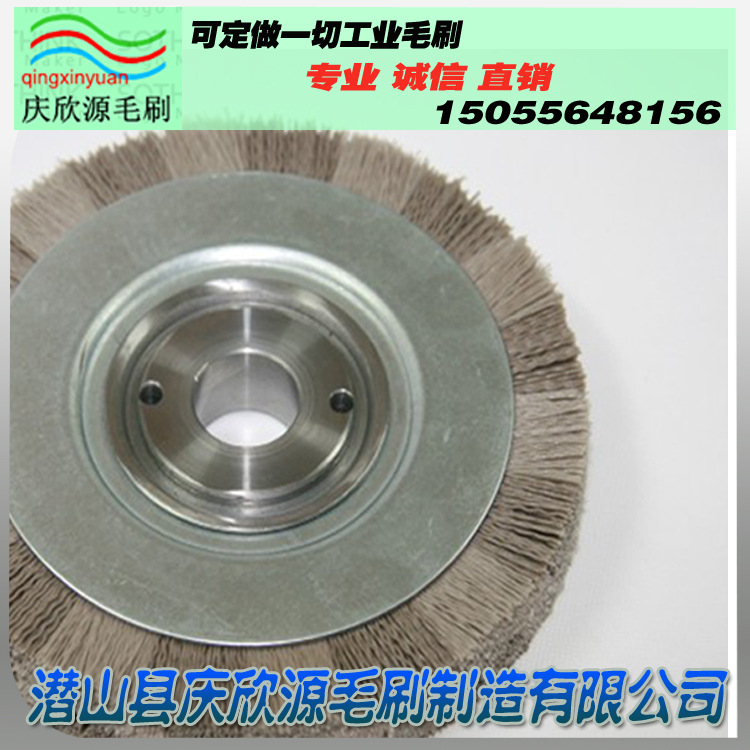

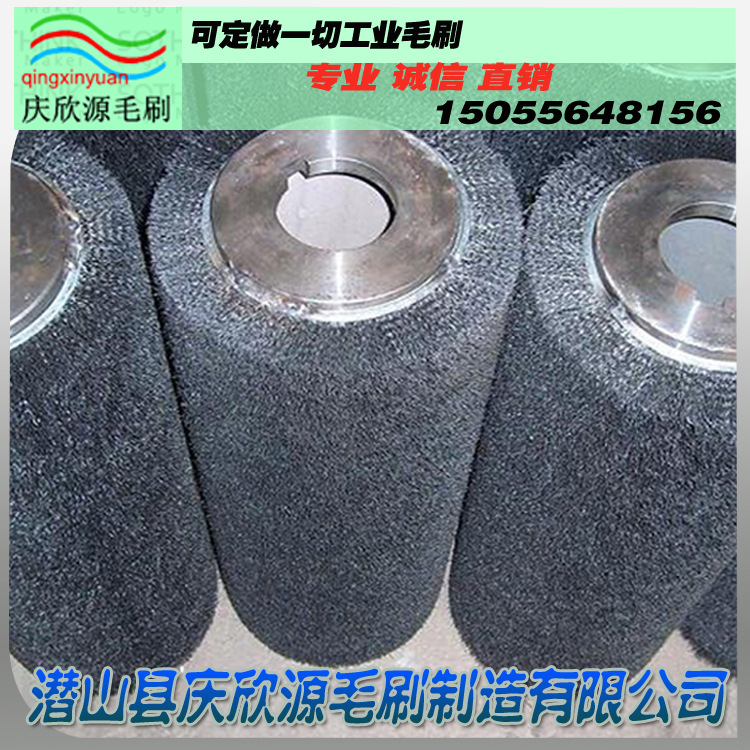

强力推荐砂布丝轮、磨料丝抛光轮 、磨料丝轮 、工业毛刷质量保证

潜山县庆欣源毛刷制造有限公司

中国 安庆

产品属性

图文详情

品牌推荐

品牌

其他

型号

多种

类型

刷辊

功能

除尘

规格尺寸

多种mm

重量

多种kg

种类

磨料丝轮

刷丝材料

可定制

形状

圆形

尺寸

可定制(mm)

用途

机械

加工定制

是

材质

可定制

全长

可定制(mm)

刷毛长度

可定制(mm)