功能特点:Function characteristic

♦ 加工面料范围广、切口平滑无飞边、自动收口、无变形、图形可通过电脑随意设计等特点。

♦ Processing a wide range of fabrics , edge smoothing , automatic close-in , without deformation , graphics design random by computer.

♦ 贴布绣切割(绣前切割和绣后切割)、异形商标切割、服装裁片、皮革镂空、成衣加工、牛仔喷花等服装辅料表面的切割与雕刻,可以对单层或多层布料一次性切割、打孔、雕花。

♦ Embroidered patch cutting(before and after embroidered cutting), profiled trademark cutting , clothing pieces , pierced leather , garments processing ,cowboy fountain of supplies , clothing cutting and engraving on the surface , the one-time single-layer or multi-layer fabric cutting , drilling , engraved.

♦ 采用高性能的激光雕刻切割控制平台—RDLC320-A控制系统。

♦ Use the laser industry’s most advanced control system—RDLC320-A control system.

♦ 采用独特的智能预测算法和改进型的控制算法,确保速加工、平稳、高效。

♦ Unique intelligent predictive algorithm and improved control algorithm to ensure that processing hight speed , smooth and efficient.

♦ 运行速度,激光能量实时可调,极大地方便了客户的操作。

♦ Cutting energy automatic compensation function , cutting greatly improved results.

♦ 切割能量自动补偿功能,切割效果得到极大改善。

♦ Operational speed ,laser energy real-time tunable , and very easy for customers to operate.

♦ 可同时存储多个文件,支持断电数据保存的永久文件存储区。

♦ Can also store more documents to support power-fail data retention of permanent document storage area.

♦ 采用PC数据线,NET网线、U盘等多个数据输出功能,大大方便了客户的实际操作。

♦ Uses the PC cable, NET cable, U disk, and other data output function, greatly facilitate the customer's actual operation.

应用领域:Application domain

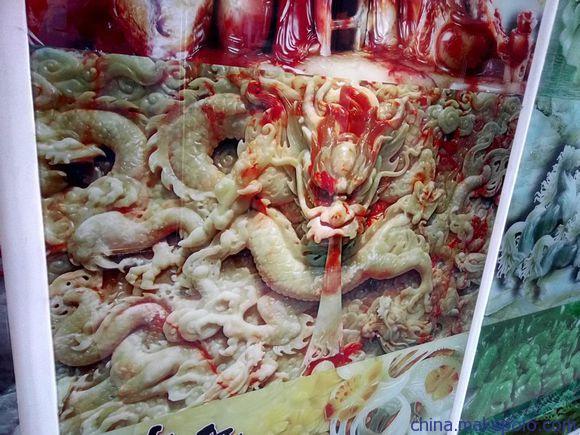

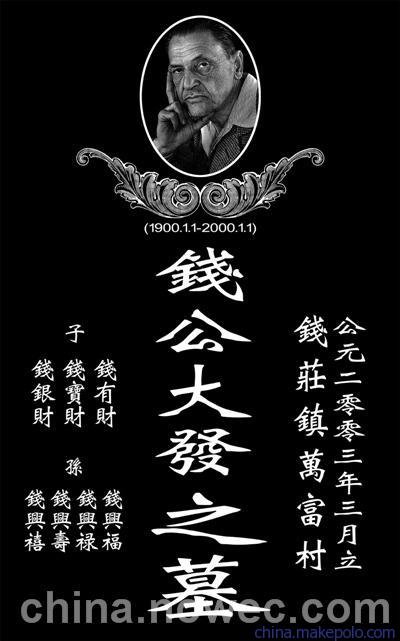

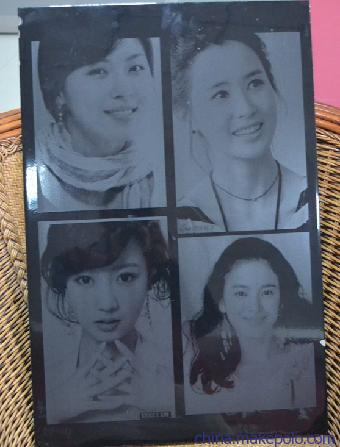

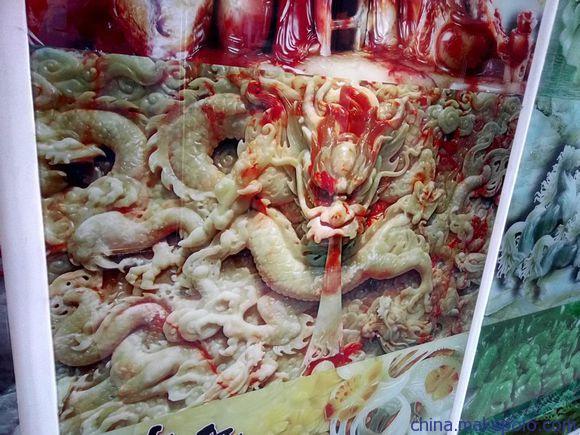

服装贴布绣、长短毛绒面料、皮毛、织唛、商标切割;服装辅料镂花、打孔、切边;皮革打孔、放样、开料;有机玻璃、塑料、PVC类、纸类、木竹等切割;木竹、陶瓷、花岗岩、影雕行业雕刻。

Cloth embroidery , babel , trademark cutting , clothing accessories embroidery , holing , cutting ,leather-holing ,sampling ,tooling ,organic glass , plastics ,PVC, paper , wood and bamboo cutting , wood and bamboo ,ceramics ,granite ,engraving.

技术参数Technical parameter

产品型号Product Model | SK-1209 | SK-1410 | SK-1610 | SK-1810 |

工作面积Working Area | 1200*900mm | 1400*1000mm | 1600*1000mm | 1800*1000mm |

外形尺寸dimension | 1790*1420*1100mm | 1980*1600*1100mm | 2180*1640*1100mm | 2380*1640*1100mm |

机器自重Weight | 260kg | 290kg | 320kg | 350kg |

机器功率Total power | 800W/1000w | 800W/1000w | 800W/1000w | 800W/1000w |

激光功率Laser Power | 50/60/80/100w | 50/60/80/100w | 50/60/80/100w | 50/60/80/100w |

电源功率Electrical source power | 400w | 500w | 500w | 500w |

最小线宽min line width | 0.05mm | 0.05mm | 0.05mm | 0.05mm |

定位精度positioning accuracy | ≤±0.01mm | ≤±0.01mm | ≤±0.01mm | ≤±0.01mm |

电源Power Supply | AC220V±10%,50Hz |

工作温度Working Temperature | 0℃-40℃ |

工作湿度Working humidity | 5-95%无凝水 no condensate water |

支持图文格式Drawing Format | BMP、PLT、DST、DSB、DXF、GIF、JPGE、PCX、TGA、TIFF、CDR、and so on |

最小形成文字Smallest Character | 汉字/Chinese2mm×2mm,英文/English1mm×1mm |

分辨率resolution | ≤2500dpi |

切割速度Cutting speed | 0-300mm/s视材料 according to material |

雕刻速度Engraving speed | 0-1000mm/s视材料according to material |

联系方式:

姓名:梁先生

手机:13736609534 电话:0577-65159389 传真:0577-65159389

地址:浙江省瑞安市莘塍工业区华山路41号(104国道边下山根村)

邮箱:cnsunke@126.com

网址: