2015南京展会Z3040单立柱摇臂钻床40钻孔模具加工优选

滕州市大兴机床有限公司

中国 枣庄

产品属性

图文详情

品牌推荐

品牌

大兴

型号

z3040×10摇臂钻床

类型

摇臂钻床

用途

通用

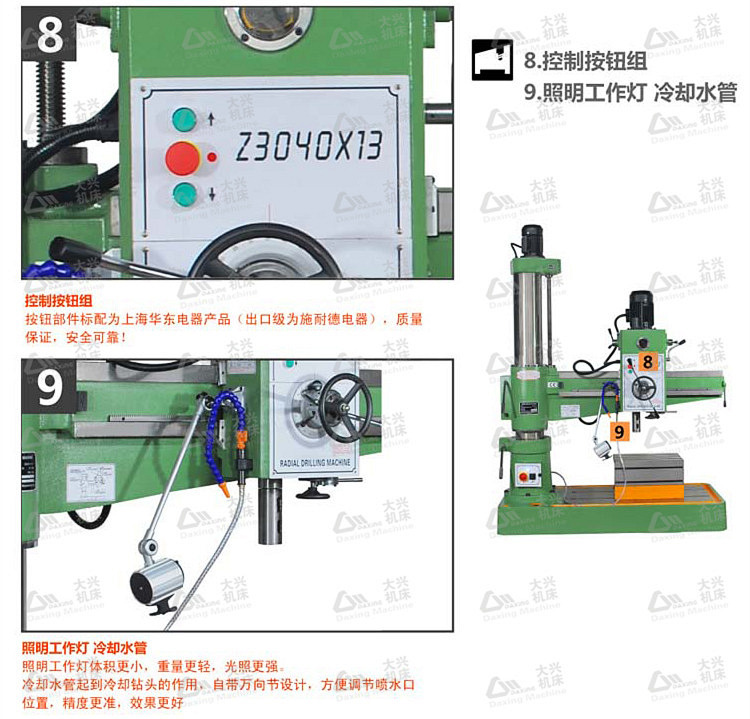

控制形式

人工

精密程度

精密

自动程度

半自动

布局形式

立式

适用行业

通用

轴数量

单轴

作用对象材质

金属

最大钻孔直径

40mm

最大钻孔深度

200mm

工作台面宽度

390mm

工作台面长度

540mm

主电机功率

2.2KW

主轴转速范围

75/130/240/380/660/1200rpm

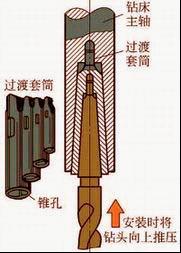

主轴孔锥度

莫氏4

外形尺寸

1500*705*2200mm

重量

1300kg

主轴进给量级数

3