铝焊料

1、优异的流动性及润湿铺展性能。

2、良好的耐腐蚀性能。

3、易操作,母材不易融化。

4、材料符合ROHS指令要求

5、无腐蚀钎剂,性质稳定,不吸潮,焊后无需酸洗

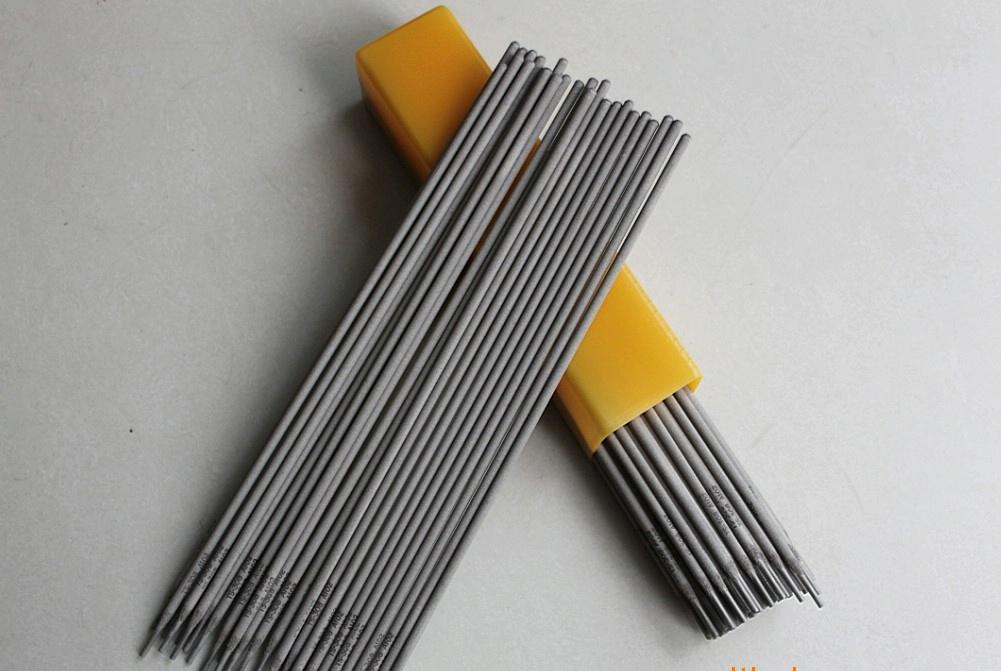

碳钢焊条

碳钢焊条可进行全位置焊接,焊接工艺性能良好,飞溅少,成形美观,脱渣好,引弧和再引弧好。用于焊接一般碳钢结构(造船,桥梁,建筑和机械结构焊接),适用于薄板小件和等级低的低合金钢,如09Mn2等。

一般规格:(mm)

2.0x300

2.5x300

3.2x350

4.0x400

5.0x400

包装: 2.5或5公斤/盒,20公斤/箱.

AWS E6013

化学成分(%):C Mn Si S P ≤0.12 0.3-0.6 ≤0.35 ≤0.035 ≤0.040

AWS E7018

化学成分(%):

Welding ElectrodesC Mn Si S P ≤0.12 ≤1.6 ≤0.75 ≤0.035 ≤0.040

Description:

AWS E6013 is a low-carbon steel electrode with a high titaniume coating and can be used on AC. or DC . It has excellent welding technological properties . The arc is stable . The spatter is small. The slag viscosity is moderate. It can be used freely . The slag is easy to clean . The welded seam is smooth and fine and easy to restrike the arc.

Application:

Suitable for welding sheet metal structure made of low-carbon steel , such as ships, vehicles, building, and general machinery.

Chemical Composition of Wire(%):C Mn Si S P ≤0.12 0.3-0.6 ≤0.35 ≤0.035 ≤0.040

Mechanical Properties of Deposited Metal:Test Item σb(MPa) σc(MPa) δs(%) AKV(J) Guarantee Value ≥420 ≥330 ≥17 -

Recommended Welding Current:Electrode Diameter(mm) 2.0 2.5 3.2 4.0 5.0 Current Range(A) 40-70 50-80 80-120 150-190 180-240

AWS E7018 Welding Electrodes

Description:

AWS E7018 is low-hydrogen potassium coating carbon steel welding rod and can be used on AC. or DC . It has excellent welding technological properties. It can be used various composition . Its evident trait is composed of Fe power and can reduce welding layer.

Application:

Suitable for welding important structures made of low alloy steel.

Chemical Composition of Wire(%):C Mn Si S P ≤0.12 ≤1.6 ≤0.75 ≤0.035 ≤0.040

Mechanical Properties of Deposited Metal:Test Item σb(MPa) σc(MPa) δs(%) AKV(J) Guarantee Value ≥490 ≥400 ≥22 ≥27(-30℃)

Recommended Welding Current:

Electrode Diameter(mm) 2.0 2.5 3.2 4.0 5.0 Current Range(A) 60-90 90-120 120-150 170-200 210-250