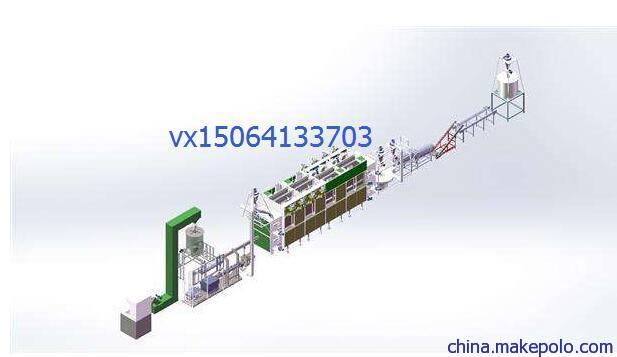

宠物食品生产线是专门为猫、狗等宠物生产日常食品和保健功能食品而研制开发,采用原料预处理调质系统,大幅度提高产量和降低能耗,能够满足客户对产量和品质的不同需求,同时在工艺上注重产品的适口性和科学的营养配比,使产品易于消化吸收。以此生产线为基点,我公司愿与行业内众多客商达成多层次、全方位的合作。

宠物饲料加工设备工艺组成:

1、拌粉机:根据生产线产量的不同选用不同型号的拌粉机,主要三种机型给您选择选用BFJ-I、BFJ-II、BFJ-III。

2、上料机:利用电机为动力螺旋式输送,确保上料方便快捷。

3、膨化机:根据生产线产量的不同选用不同型号的膨化主机,产量可从100kg/h--600kg/h不等,可以玉米粉、谷粉、骨粉、肉粉等为原料,具体产品形状可更换模具。

4、提升机:将饲料输送到烤箱,提升机的高度根据烤箱确定,也可选用风送机。

5、多层烤箱:烤箱多为电烤箱,温度在0-200度之间通过控制柜自行调节,内部为不锈钢双层网袋,烘烤时间可以根据速度调节,有三层、五层、七层不锈钢烤箱;

6、调味线:有八角筒、圆筒、提升单滚筒、双滚筒调味线,根据产量、产品性质配置,

7.振动筛:筛去多余碎料以及多余的外撒料,确保包装

产品特点: #、膨化成型率高,可根据模具做多种异形3D狗粮 #、自动化程度高,各参数均可调节 #、双螺杆均采用高温耐磨杆,机筒采用调质优质钢 #、设备稳定,易于拆卸维修

The process composition of pet feed processing equipment:

1, mixing machine: according to the production line output of different models of different types of mixing machine, the main three types of models for you choose to choose BFJ-I, BFJ-II, BFJ-III.

2, feeding machine: using motor as the power screw conveyor to ensure convenient and quick feeding.

3, extruder production line production: according to different use different types of expanded production host, ranging from 100kg/h--600kg/h, can Gu Fen, corn powder, bone meal, meat meal as raw materials, the specific shape of the product can replace the mold.

4, elevator: feed the feed to the oven, the height of the hoist is determined according to the oven, and the fan can be used.

5, multi oven: oven for electric oven, the temperature at 0-200 degrees between the control cabinet through self-regulation, the internal stainless steel double bag, baking time according to the speed regulation, there are three layers, five layers and seven layers of stainless steel oven;

6, seasoning line: there are octagonal cylinder, cylinder, lifting single drum, double roller seasoning line, according to the production and product nature,

7. vibrating screen: sifting redundant material and superfluous spice to ensure packing

加工样品

产品布局: