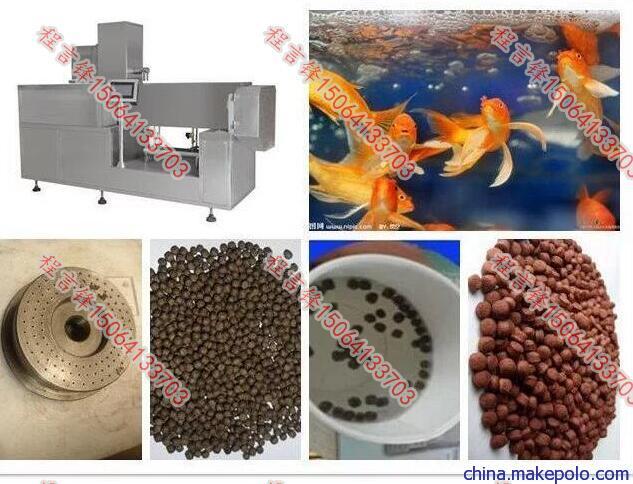

干法小产量FG65饲料膨化机/鱼饲料颗粒机】狗粮生产线

设备工艺咨询15064133703

宠物食品生产线是专门为猫、狗等宠物生产日常食品和保健功能食品而研制开发,采用原料预处理调质系统,大幅度提高产量和降低能耗,能够满足客户对产量和品质的不同需求,同时在工艺上注重产品的适口性和科学的营养配比,使产品易于消化吸收。以此生产线为基点,我公司愿与行业内众多客商达成多层次、全方位的合作。

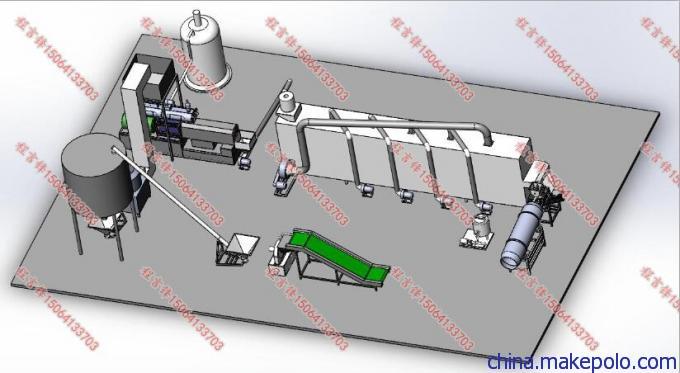

宠物饲料加工设备工艺组成:

1、拌粉机:根据生产线产量的不同选用不同型号的拌粉机,主要三种机型给您选择选用BFJ-I、BFJ-II、BFJ-III。

2、上料机:利用电机为动力螺旋式输送,确保上料方便快捷。

3、膨化机:根据生产线产量的不同选用不同型号的膨化主机,产量可从100kg/h--600kg/h不等,可以玉米粉、谷粉、骨粉、肉粉等为原料,具体产品形状可更换模具。

4、提升机:将饲料输送到烤箱,提升机的高度根据烤箱确定,也可选用风送机。

5、多层烤箱:烤箱多为电烤箱,温度在0-200度之间通过控制柜自行调节,内部为不锈钢双层网袋,烘烤时间可以根据速度调节,有三层、五层、七层不锈钢烤箱;

6、调味线:有八角筒、圆筒、提升单滚筒、双滚筒调味线,根据产量、产品性质配置,

7.振动筛:筛去多余碎料以及多余的外撒料,确保包装

1、双螺杆挤出机简介

双螺杆膨化食品设备是采用国际先进的双螺杆挤压膨化技术,结合我公司多年来膨化食品技术研究的丰富经验研制开发的适合我国国情的膨化食品设备,该设备的特点是:根据市场的需求,可分别以玉米,大米,小米,黑米,绿豆,荞麦,燕麦等无五古杂粮为原料,通过设备的强制挤压,膨化,成型干燥,喷油,调料及相应的辅助工艺加工而成具有多种风味的膨化食品,夹心食品,营养食品,各类膨化休闲食品及宠物食品。该生产线设计合理,自动化程度高,产量高、工艺先进,主机采用先进的变频调速系统,强劲节能。该生产线属于国内先进水平,它的开发生产填补了国内小直径螺杆膨化设备产品单一产量小等空白。

膨化机的保养

1、箱体轴承应及时加注润滑油脂,运行500小时后,要全部更换一次润滑油脂。(新机器运行前应适量加入润滑脂,运行200小时后应当换油。)

2、其他轴承部位要定期加注润滑脂。

3、螺杆、螺套等易损件在拆装过程中严禁用硬物重锤,在膨化腔上严禁放置重物或者站人。进口泵 阀门

4、膨化原料应经过清理,严防金属等异物进入机内损坏机件。

5、随时检查膨化机质量,注意更换易损件。

6、保持设备周围的清洁。

7、长期停机不用或更换膨化物料时,应将膨化腔内的物料清除干净,以免结块、霉变或者物料之间交叉污染。

8、由于接近出料口处的易损件磨损相对较快,靠近进料口一端的易损件磨损较少,所以在更换易损件时,应从出料端开始依次更换,不宜一次更换多种部件。

1. Introduction of twin screw extruder.

Twin-screw puffed food equipment is adopting international advanced twin-screw extrusion technology, combined with my company puffed food technology research for many years rich experience in research and development of puffed food equipment suitable for China's national conditions, the device is characterized by: according to the demand of the market, can be respectively to corn, rice, millet, black rice, mung beans, buckwheat, oats, etc without WuGu grains as raw materials, through the enforcement of extrusion equipment, puffing, forming dry, oil, spices and corresponding auxiliary process has a variety of flavors of puffed food, sandwich food, nutrition food, all kinds of snack food and pet food.The design of the production line is reasonable, the automation degree is high, the output is high, the craft is advanced, the host adopts the advanced frequency conversion speed regulation system, the strong energy saving.This production line belongs to the domestic advanced level, its development and production fills the domestic small diameter screw extruded equipment product single output smal

The process composition of pet feed processing equipment:

1, mixing machine: according to the production line output of different models of different types of mixing machine, the main three types of models for you choose to choose BFJ-I, BFJ-II, BFJ-III.

2, feeding machine: using motor as the power screw conveyor to ensure convenient and quick feeding.

3, extruder production line production: according to different use different types of expanded production host, ranging from 100kg/h--600kg/h, can Gu Fen, corn powder, bone meal, meat meal as raw materials, the specific shape of the product can replace the mold.

4, elevator: feed the feed to the oven, the height of the hoist is determined according to the oven, and the fan can be used.

加工样品

产品布局: