精密内齿轮计量泵 微量输送泵 加注医药泵 电池点滴采样泵-广州埃萌

AM系列内齿轮计量泵的设计,立足于为工业生产工艺提供稳定的流体输送解决方案,特别适用于微量输送系统、自动动力加料(加药)系统、采样设备(包括真空环境采样)、实验室设备、冷却统(冷媒循环泵)、铸造机械、包装机械、设消毒清洗系究、药物填加系统、化工计量系统、小试/中试装置等需要小流量、高压力、流量稳定、计量准确、无输送的场合,相于传的莫计量泵具有天然优势,传统的帥隔膜计量泵有脉冲、体积大、管路系究更复杂。

AM系列内齿轮计量泵采用微电脑闭环位置控制磁力齿轮泵的转动,计量精确,停转时泵处于制动状态,不滴液。可随意设置灌装量和停顿时间。广泛适用于医药、学校、科研单位实验室、动物保健品厂、食品饮料、精细化工、农药、大中型企业小批量生产等。可灌装:眼药水、试剂、食品、蜂蜜、洗发水、化工产品、兽药、农药等。

主要卖点

1、平稳无脉动精确输送正向位移泵,通过齿轮来提供持续的精确的流体输送配合伺服或步进电机使用,输送精度可达+/-0.2%

2、无泄漏磁力马驱动和静态O型圈密封可保证泵内介质与外界隔离

3、高差压还可以实现为低粘度液体高压输送

4、精密电机和精密控制伺服步进电机集成PC微电脑空制,OEM工业产品配套

结构原理

应用范围

Product Description

Micro annular gear pumps are miniaturized rotary positive displacement pumps. They are based on a so? called micro annular gear

principle with an externally toothed internal rotor and an internally toothed external rotor. The internal rotor has one tooth less than the external

rotor with the tooth ratios of 6/7 and 10/11 used. The manufacturing tolerances of the rotors are in the range of few micrometers.

微型环形齿轮泵是小型旋转容积泵,它们基于所谓的微环形齿轮原理,具有外齿内转子和内齿外转子,内部转子比外部转子少一个齿,齿数比为 6/7 和 10/11,转子的制造公差在几微米范围内。

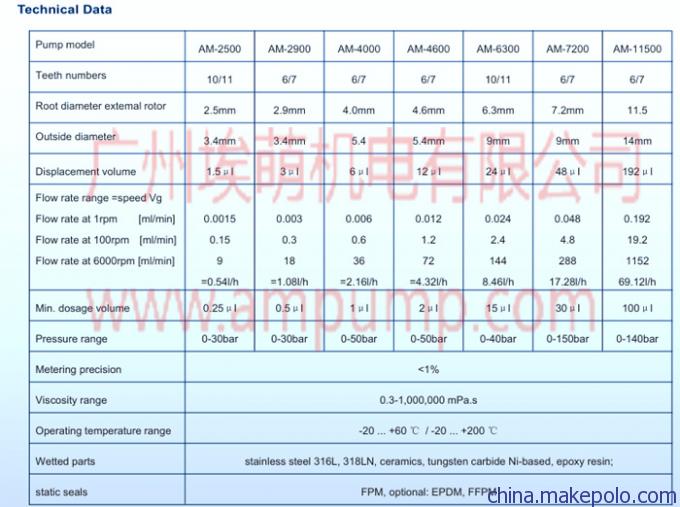

The micro annular gear pump product range consists of five different series of pumps for dosing and metering small amounts of low to

high viscous liquids. With different equipment, dosing volumes starting at 0.25 μl, flow rates ranging from 1 μl/h to 1.1 l/min as well as pressures

from 0 to a maximum of 150 bar are possible. The range of the liquid viscosity extends from 0.3 to 1,000,000 mPas. Operation in an explosion-proof area is also possible. Special features are distinguished by low pulsation, low shear stress, low dead volume, long service life,low weight and a compact structure as well as wear and corrosion resistant materials.

微型环形齿轮泵产品系列由五个不同系列的泵组成,用于计量和计量少量的低粘度到高粘度的液体。 使用不同的设备,计量体积从 0.25 微升开始,流量范围从 1 微升/小时到 1.1 升/分钟,压力范围可从 0 到 150bar。 液体粘度范围从 0.3 到 1,000,000 mPa.s。

可在防爆区域内进行操作使用。 特点是流量连续低脉动,低剪切应力,使用寿命长,重量轻,结构紧凑以及耐磨和耐腐蚀材料。

Highly precise metering volumes in the microliter to milliliter range and the smallest volumetric flows constitute the requirements placed on pumps in the fields of analysis technology, chemistry, medicine, biotechnology and mechanical engineering. Thanks to their high process stability, the micro annular gear pumps developed and produced by us make this new dimension in metering technology available to a wide range of applications.

微升到毫升范围内的高精度计量体积和最小的体积流量,构成了分析技术,化学,医学,生物技术和机械工程领域对泵的要求。 由于其高精度的工艺稳定性,我们开发和生产的微型环形齿轮泵将这一新的尺寸应用于各种计量技术中。

Operation PrincipleBoth rotors, which are eccentrically mounted, are intermeshed with their cycloid gearing. As a result a system of several sealed pumpingchambers ex-lsts at all times. With a tooth ratio of 6/7 a chamber number of six results.

两个偏心安装的转子都与握线齿轮合。因此,一直有多个密封泵腔室的形成。齿数比为67时,泵腔室数目为六个。

小微精加工的齿轮

The shaft of the micro annular gear pump is connected to the intemal rotor and is powered by a precisely controlled electric motor. Theexternal rotor is mounted rotatable and is driven by the internal rotor

微型环形齿轮泵的轴连接到内部转子井由精而控制的电动机驱动,外转子可旋转地安装并由内转子驱动

As the rotors tum around their offset axes, the volume of the pumping chambers increases on the induction side and simultaneouslydecreases on the delivery side of the pump. A homogeneous and low pulsation flow rate is generated between the kidney shaped inlet andoutlet which also combines several pumping chambers at the same time. The pump s con veying direction is reversible. however, arecommended direction of rota tion exists

当转子绕偏置轴转动时,泵腔空的容积在吸入側增加,同时在泵的输出侧减小。在肾形入口和出口之间产生均匀且低脉动的流速,其同时结合了多个泵腔室。泵的输送方向是可逆的,但推荐同一个旋转方向。