特点:

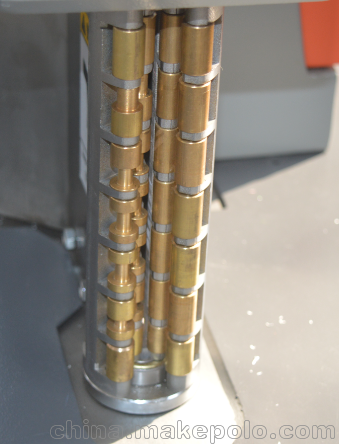

1.弯弧采用伺服电机,拍弧式,小弧成型度高

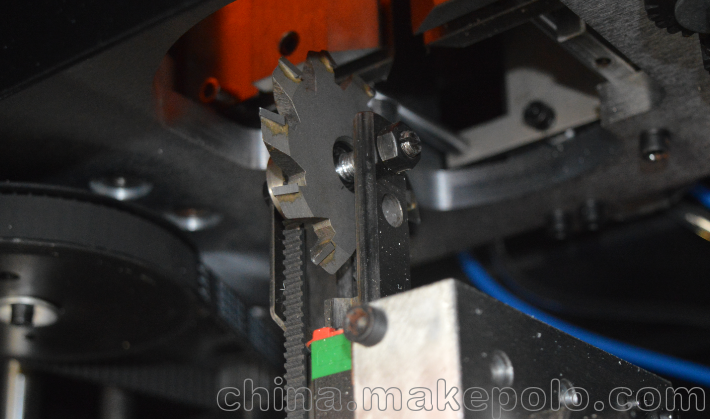

2. 方轨定位切割,切割采用直流无刷调速电机,可调速,切割圆滑、细腻,噪音小,性能稳定,更好的适用各种材料。

3. 材料加工高度可到130mm,弯弧力度轻松完成1.2mm厚130mm宽的材料

4.方轨定位切割,保证切割稳定

5.闭环式检测系统,走料长度的长远精确保证,确保加工后的成品与源文件误差<0.1

6.弯弧器回弹系数智能补偿,确保各种材料的成型精度

7.设备操作调试简单,高度符合机械原理,配件标准化设计,性能稳定。性价比高,是高档LED字,精品金属发光字的首选经济实用型设备。

1.Use servo motor for bending ,in pat bending way ,easy form a small arc

2.With brushless Dc cutting motor, adjustabie speed application of various materials.

3.Material width maximum 130mmeasily bend 130mmwidth 1.2mmaiuminum material

4.lmported side rails positioning ,to ensure the cutting stability 5.With the closed loop self-tese system, the device features high measuring precision in the long yun The whole error is less than 0.1mm comparing with the acrylic panel.

6.Curved arc is rebound coefficient intelligent compensation to ensure the acc uracy of various materials forming .

7.Simpel operation , highly consistent with mechanical principles standard parts ,stable quality

详细参数

工作原理 | 高精度自测自动进料、自动整料、自动开槽、自动弯弧 |

型号 | RY-130 |

加工型材 | 铝型材,超级字材料,平板铝边条等金属类 |

开槽弧度 | 45度~135度(平板型材无角度限制) |

弯弧半径 | ≥5mm |

型材宽度 | ≤130mm |

型材厚度 | 0.3-1.5mm |

设备功率 | 1000W |

文件格式 | dxf, ai,plt |

设备尺寸 | 1400*1350*700mm |

设备重量 | 230KG |

额定电压 | 220V |

工作气压 | 0.6-0.8Mpa |

Detailed parameters

Working principle

| POST-precision automatic feed, automatic monolith automatic slot, automatic curvedarc |

Model | RY-130 |

Processing profile | Aluminum, iron, galvanized sheet metal |

Slotted radian | 45 degrees to 135 degrees (flat profile no angle limit) |

Arc bending radius | ≥5mm |

Profile width | ≤130mm |

Profile thickness | 0.3-1.5mm aluminum |

Power Equipment | 1000W |

File Format | dxf, ai, plt |

Equipment size | 1400 * 1350*700mm |

Weight | 230KG |

Rated voltage | 220V |

Working pressure | 0.6-0.8Mpa |

、