The main sources of zinc in wastewater of electroplating and metal processing industry are towing liquid of electroplating or pickling. Contaminants are transferred to the rinse water through the metal rinse process. The pickling process involves dipping a metal (zinc or copper) in a strong acid to remove the oxide from the surface and then dipping it in a brightening agent containing a strong chromic acid for polishing. The wastewater contains a large amount of hydrochloric acid, zinc, copper and other heavy metal ions and organic brightening agents, etc., which are highly toxic. Some of them also contain carcinogenic, teratogenic and mutagenic toxic substances, which are extremely harmful to human beings. Therefore, the electroplating wastewater must be seriously recycled and treated to eliminate or reduce its pollution to the environment.

电镀和金属加工业废水中锌的主要来源是电镀或酸洗的拖带液。污染物经金属漂洗过程又转移到漂洗水中。酸洗工序包括将金属(锌或铜)先浸在强酸中以去除表面的氧化物,随后再浸入含强铬酸的光亮剂中进行增光处理。该废水中含有大量的盐酸和锌、铜等重金属离子及有机光亮剂等,毒性较大,有些还含致癌、致畸、致突变的剧毒物质,对人类危害极大。因此,对电镀废水必须认真进行回收处理,做到消除或减少其对环境的污染。

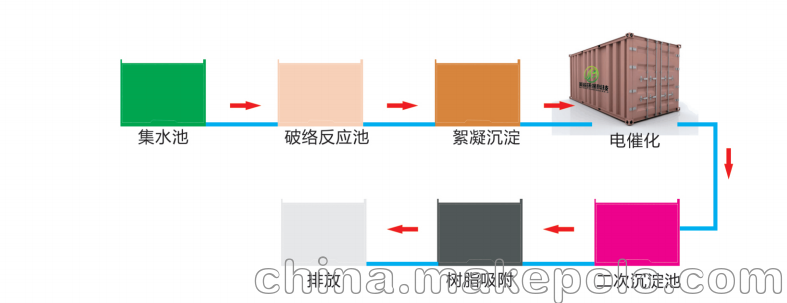

The current process of electroplating wastewater is: flocculation + sodium hypochlorite breaking + pH regulating + capturing agent + pH regulating + resin adsorption

电镀废水目前采用的工艺为:絮凝+次氯酸钠破络+调pH+捕捉剂+调pH+树脂吸附

Electroplating wastewater, electroless plating wastewater, PCB industry wastewater and other heavy metal wastewater treatment projectsThe resin adsorption process can adopt the special chelating resin CH-90 imported from cohays.

电镀废水、化学镀废水、PCB行业废水等含重金属废水处理项目,树脂吸附环节可以采用科海思的专用除重金属螯合树脂CH-90进口树脂。Ch-90 is suitable for selective removal of palent metal ions from monovalent metal ions in process or wastewater. DivalentThe removal applications of the bivalent metal ions, such as electroplating and metal pickling, hydrolytic metallurgy; Battery manufacturingIndustrial applications such as lead removal, electronics, etc. metal ions can be easily separated from univalent metal ions, such as plasma.

CH-90树脂的主要优势有:

1、CH-90树脂吸附饱和周期时间长(具体时间根据具体项目觉得);

2、CH-90树脂对于弱酸型螯合剂产生的络合镍具有良好的吸附效果;

3、CH-90树脂使用条件广泛,可以用于高盐水、PH值0-14的范围内去除重金属;

4、CH-90树脂吸附饱和之后再生时间短(只需一小时左右);

5、CH-90树脂处理精度高,树脂吸附之后出水可以做到0.02ppm以下;

6、CH-90树脂吸附量大,理论吸附值可以达每升树脂吸附65g铜;实际项目最高已经做到每升树脂吸附45g铜;

7、CH-90树脂对于二价金属离子具有选择吸附效果,在不同PH值环境下吸附优先吸附不同离子

9、CH-90树脂在相同项目中树脂使用量少(一般为国产树脂的三分之一左右):

CH-90树脂典型参数:

型式 : 弱酸型阳离子交换树脂

结构 : 巨孔状交叉键结聚苯乙烯

官能基

物理型式: 含水球状

离子型式: 钠

粒径分布 :16to50

粒径大小 :0.3to1.2mm

总交换容量 :1.8meq/ml (H+)

膨胀系数 :H+ → Na+ 20%

含水份: 45-50%

pH 作范围:0to14

溶解率 : 不溶解于任何溶剂

逆洗沉降密度 :0.72to0.79g/ml

1、电镀、化学镀清洗废水

2、PCB行业生产废水

3、有色金属冶炼行业、有色金属加工酸洗废水

4、垃圾渗滤液含重金属废水

5、矿山坑内排水、选矿厂尾矿排水

6、电解、农药、医药、油漆、颜料等工业