Al > 99.997 % Total content of additive elements: 30 wt.-ppm max

Diameter / Type (µm)

Elongation (%)

Breaking Load (g)

Spool Type

Maximum Length/Spool (m / ft) 125 > 1 50 - 90 3.5” / 4” 300 / 300 150 > 1 80 - 120 3.5” / 4” 300 / 300 175 > 1 100 - 160 3.5” / 4” 300 / 300 200 > 1 150 - 230 3.5” / 4” / ConBig 500 / 300 250 > 1 200 - 300 3.5” / 4” / ConBig 500 / 200 300 > 5 280 - 400 3.5” / 4” / ConBig 700 / 200 375 > 5 450 - 650 3.5” / 4” / ConBig 400 / 100 400 > 5 500 - 700 3.5” / 4” / ConBig 400 / 100 450 > 5 650 - 850 3.5” / 4” / ConBig 300 / 100 500 > 5 850 - 1100 3.5” / 4” / ConBig 300 / 100

Testing criteria for breaking load and elongation: Testing velocity: 10 mm / min - Test length of sample: 100 mm

(*) Technical parameters: The above parameters are standard values. Customized specification is possible after clarification with Heraeus technical staff. Further intermediate dimensions possible after clarification with Heraeus technical staff.

Melting point °C 660 Modulus of rigidity kN/mm2 27 Thermal conductivity at 20 °C W/m*K 230 Linear expansion coefficient (20 – 30 °C) 10-6*K-1 25.3 Electrical Resistivity at 20 °C μcm 2.8 Rel. electr. conductivity (IACS, 20 °C, annealed) % 64.0 Resistance at ø 25 μm (20 °C) m 57.1 Temp. coefficient of elec. Resistance (0 – 100 °C) 10-3*K-1 4.14

Wire regularly spooled on polymer spools of type 3.5” PS-DF or on 4” ConBig Spools . Per spool only one single wire length. Start and end of wire get marked by adhesive tapes of different colours: start-green, end-red or per separately to be fixed agreement. Regular length per spool: see table or per separately to be fixed agreement. Mode of spooling: multiple layers. Alternative spool types by discussion with HERAEUS technical representative.

The wire surface is free from pollution, fingerprints and foreign substances. Inclusions, notches, big grooves and bends are not allowed. Slight rolling marks are permissible. Test at 12 x magnification.

Chemical Composition

Technical Parameters (*)

Material Characteristics

Mode of Delivery

Surface

BONDING WIRE

Product Type: Aluminum Wire

Product Name: AL-H11

Technical Data Sheet

Heraeus Electronics Heraeus Deutschland GmbH & Co. KG Heraeusstraße 12 – 14 63450 Hanau, Germany www.heraeus-electronics.com

Asia Pacific Phone +65 6571 7677 electronics.apac@heraeus.com

China Phone +86 21 3357 5457 electronics.china@heraeus.com

Europe, Middle East and Africa Phone +49 6181 35 3069, +49 6181 35 3627 electronics.emea@heraeus.com

The descriptions and engineering data shown here have been compiled by Heraeus using commonly-accepted procedures, in conjunction with modern testing equipment, and have been compiled as according to the latest factual knowledge in our possession. The information was up-to date on the date this document was printed (latest versions can always be supplied upon request). Although the data is considered accurate, we cannot guarantee accuracy, the results obtained from its use, or any patent infringement resulting from its use (unless this is contractually and explicitly agreed in writing, in advance). The data is supplied on the condition that the user shall conduct tests to determine materials suitability for particular application.

Americas Phone +1 610 825 6050 electronics.americas@heraeus.com

Spool description: 3.5”-PS-DF Core diameter: 48 mm Flange diameter: 82.5 mm Internal diameter: 10.2 mm With over windings: 25 mm Overall width: 30.7 mm Material: Polystyrene

Spool description: ConBig Core diameter: 48 mm Flange diameter: 120 mm Internal diameter: 10.3 mm Overall width: 40 mm Material: Polystyrene

Alternative spool types by discussion with HERAEUS technical representative.

Spools are single packed and arrested in a suitable, dust-safe polymer box, preventing ribbon and spool from damages and pollution.

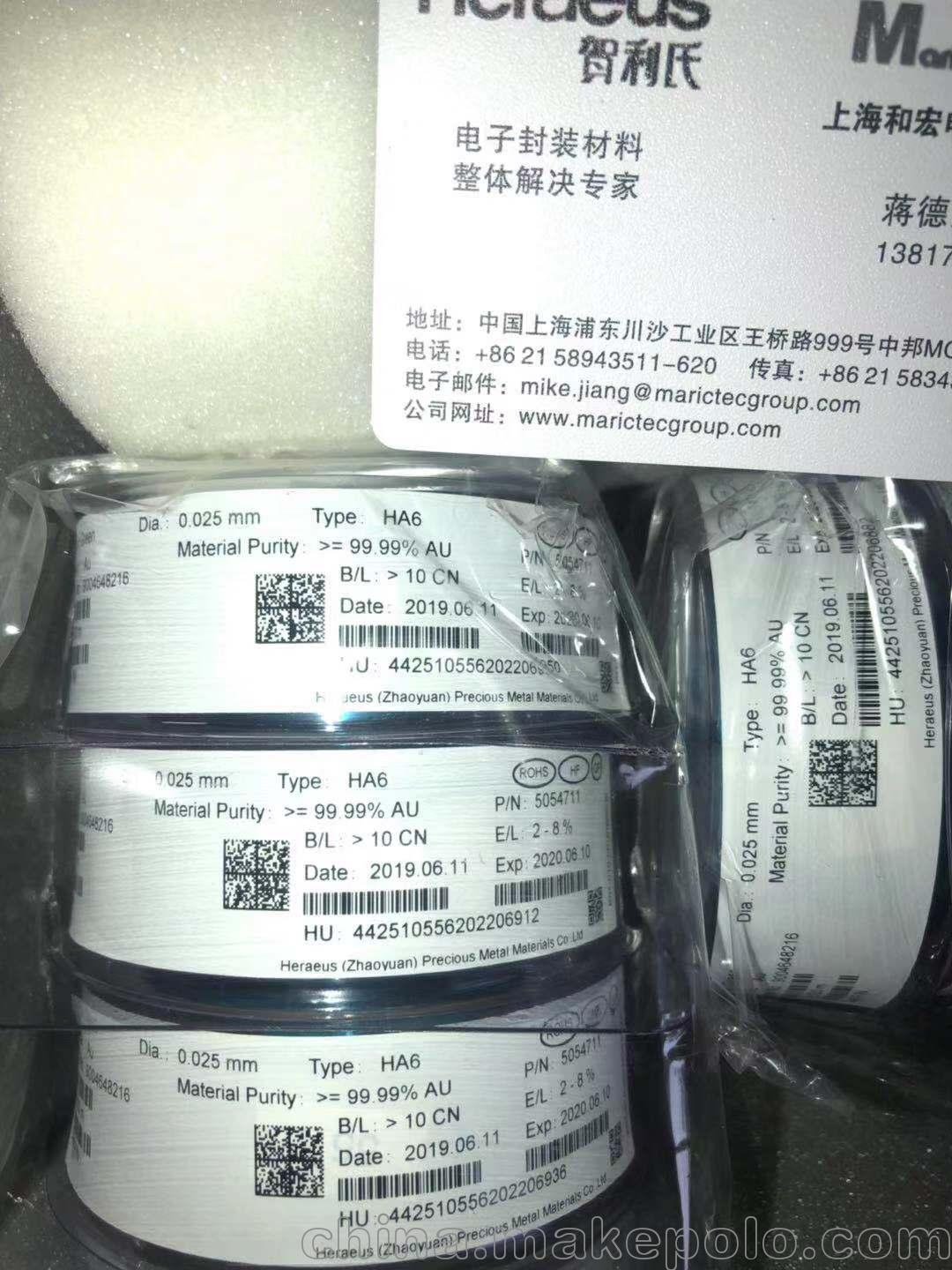

Each single packed unit gets marked with a label carrying the following information: a) Wire type b) Specified diameter c) Length per spool d) Specified elongation e) Specified breaking load f) Lot no. g) Exp. date (6 month from time of mfg. date or as defined on the product label) h) Supplier name i) Description of wire start (tape colour) j) Barcode (code 39) for adequate parameters

A Certificate of Quality gets supplied enclosed to each lot, providing the following information at minimum:

- Product identification (name, material, lot no., order no., customer name, mfg. & exp. date) - Specification / tolerances / spool data - Quality inspection test data / results

Customer specifications can become valid in addition to this technical data sheet in case they have been set in place by mutual agreement.

Spool