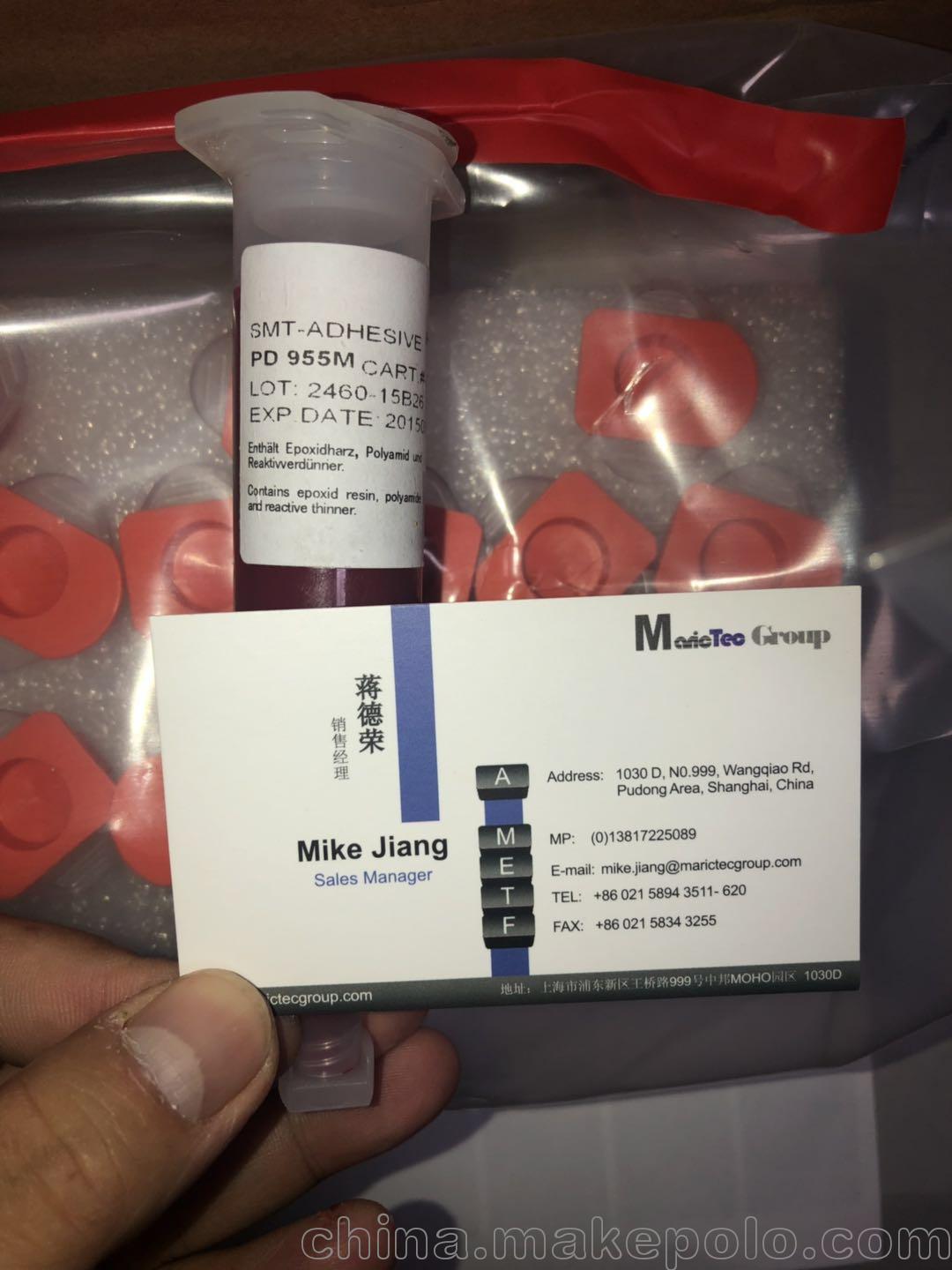

Technical datasheet Thermosetting Polymer SMT-Adhesive

PD 944 and PD 945 are thermosetting single-component, solvent-free polymer adhesive, developed especially for the surface mounting of SMT components on to PCBs and for use on bare substrates. The different between the adhesives is in the viscosity. The Pd 945 has the higher viscosity.

Special Advantages

• Very wide processing window, no tendency for stringing • Suitable for standard and for high-speed dispensing • High green strength, especially PD 945

• Excellent adhesion with standard and also with the difficult to glue components • High surface insulation resistance (SIR) • Consistent batch-to-batch quality

• Very low humidity absorption. Steep temperature increases and very short curing times are possible without danger of formation of air bubbles or worse adhesion

Colour: red Density: 1,2 g/cc Glass transition temperature: Approx.: 80°C Homogeneity: No particle > 50 micron Adhesion: > 25N/mm² at room temperature, after curing in conventional box oven, 4 min / 125 °C, Cu-nail on SO component, with a low-stress incapsulation compound

Viscosity @ (D)= 30 [s–1] PD 944: 15-50 [Pa•s] PD 945: 30-65 [Pa•s] Haake Rotovisco RV 20, PK 100, PK I/2°T, plate-cone, without border Temperature: 23°C Program: Ascending curve 0-40 s-1, 6 min

!

Surface insulation resistance and electrolytic corrosion property : see reverse..

"

The adhesive is suitable for : - machine and manual dispensing : PD 944 and PD 945 - Screen printing : PD 944 - Stencil printing : PD 944 and PD 945 - Pin-transfer technique: PD 944

2 / 3

# $% "

The standard curing conditions are: 125°C / 3 minutes. Max. curing temperature should not higher than 200°C. The min.* curing times are shown in the following table..

°C 100°C 125°C 150°C 180°C Minutes 8´ 3´ 1,5´ 1 * Optimal curing conditions depend on the curving oven.

& $ "

Before curing: • The uncured adhesive can be removed with Zestron HC and other Zestron and Vigon cleaning materials – see separate application recommendations. • The cleaned parts must be completely dry before installing them on the machine.

After curing: • Warm up to the splice to over 100°C with hot air • remove remaining adhesive with one sharp tool.

’ ( "

• The adhesives are available in various machine-specified syringes.

"

• 6 months in a refrigerator, at a storage temperature of 5-12 °C. • Storage in refrigerator is recommended. • Store syringes vertically, with tip down. • Remark : Storage at temperature >30°C should be avoided