产品型号:PKD200,300,400,500,630,700,800(非标可定制)

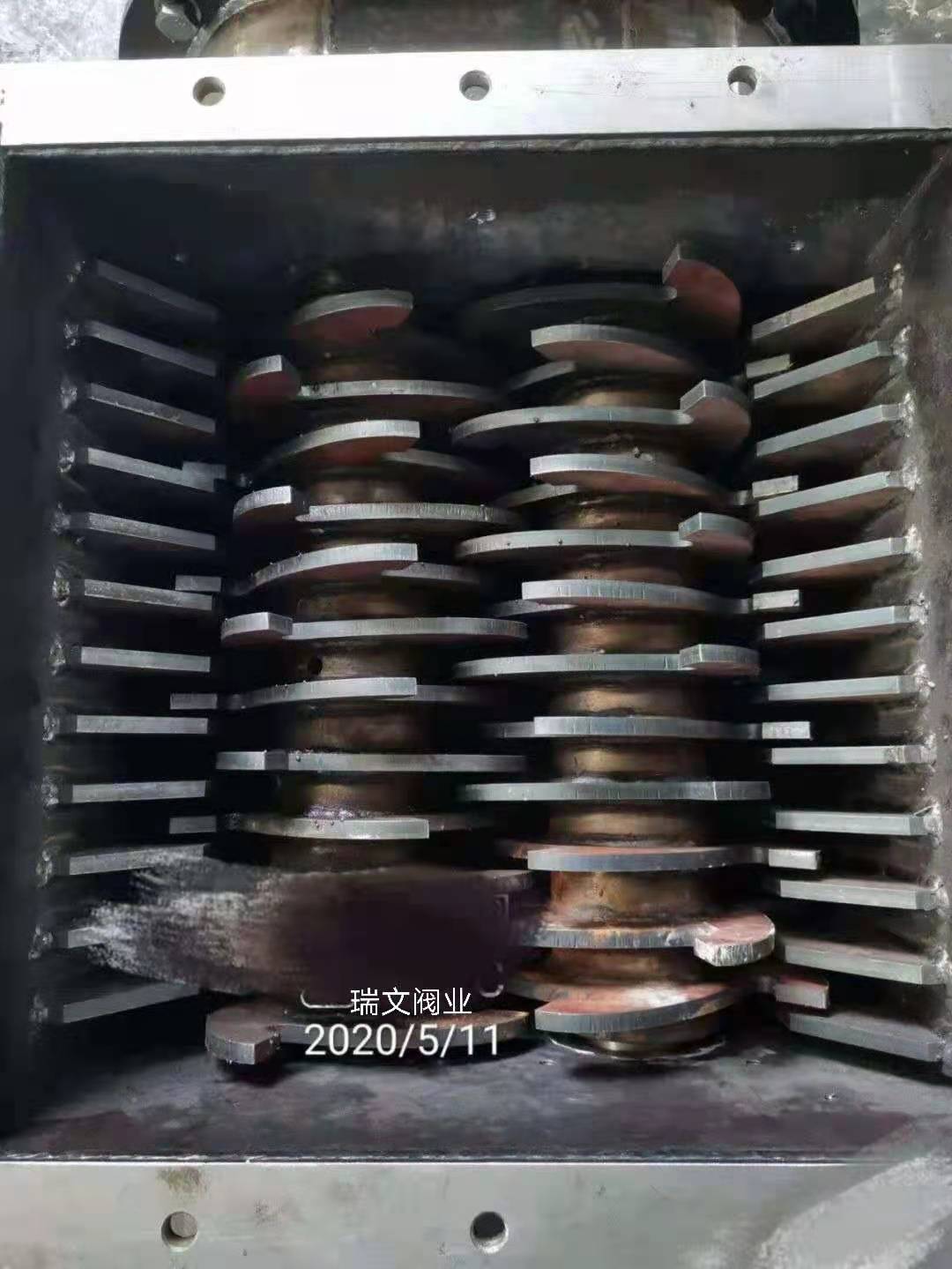

简介:块料破碎阀主要功能是破碎卸料器物料流中的块料,这些块料是物料在库内或仓中因受潮而形成。物料中的块料由于通过不了卸料器的卸料口,因此会造成物料阻塞并引起流量调节阀产生非真实流量的虚假信号,轻者影响工艺系统的正常生产,重者则会因为虚假信号造成原料和燃料之间的比例严重失调,从而造成燃烧设备中的温度过高,导致设备事故。块料破碎阀可水平或垂直安装在卸料出口处卸料设备的入料端,如流量调节阀或气动切断阀的前部。当物料中出现较大块状物时,可立即将其破碎,以防止这些大块物料堵塞卸料阀门的通道,保证通畅卸料。破碎阀的转子上安装有放射状布置的破碎爪,拨动块料物料通过栅格并将其破碎。块料破碎阀的运转安全性是通过在电控箱中集成的电机转速检测装置来保证,当物料中的某些块料物料无法破碎而卡住转子时,转速检测装置将报警并自动反转,将无法破碎块料物料推开后再进行正转。当正转或反转都被卡住时,破碎阀则自动停机,等待排除故障后再运行。转速检测装置为选配装置,有此要求时需要在设备订货时说明。

江苏瑞文阀业设备有限公司是一家专注于电气动执行器和各类阀门产品研究、开发、生产及销售的技术企业,总部及研发基地设立于风景秀丽的扬州西湖镇,公司技术和研发实力雄厚,全国多个重点工程项目的参与者,并被认定为“高新技术企业”。

公司自成立以来,始终坚持以人才为本、诚信立业的经营原则,荟萃业界精英,将先进的信息技术、管理方法及企业经验与国内企业的具体实际相结合,为企业供给全方位的解决方案,帮忙企业提高管理水平和生产本事,使企业在激烈的市场竞争中始终坚持竞争力,实现企业快速、稳定地发展。

优良的产品、优良的服务、优良的信誉,江苏瑞文阀业设备有限公司已在石油,化工,建材,矿山,轻工,电站,冶金,水泥厂消防,污水处理,脱硫脱酸等诸多领域取得优越的成绩,完成众多大型项目的配套服务,也愿意成为您可信赖的长期合作伙伴。

公司配套产品有:变频智能执行器,部分回转及多回转电动执行器,直流电动执行机构,伯纳德机型,罗托克机型,扬州电动头,DKJ系列,IQT系列,ISO 系列及精小型配套阀门使用执行器,除尘设备,物料阀门,空气斜槽,均化库设备,各种卸料阀,块料散装机等欢迎前来交流合作,希望与广大客户和从事相关行业的朋友结为友好的合作关系携手共进,走向辉煌!

The main function of the block is to the blocks in the material flow of the unloader. These blocks are formed by moisture in the warehouse or warehouse.

Because the lump material in the material cannot pass through the discharge port of the discharger, it will cause material blockage and cause the flow control valve to generate false information of untrue flow. In light cases, it will affect the normal production of the process system, and in serious cases, it will cause serious imbalance between raw materials and fuel due to false signals, resulting in temperature rise in the combustion equipment and equipment accidents.

The block crer can be installed horizontally or vertically at the discharge outlet, such as the front of the flow regulating valve or pneumatic shut-off valve. When a large piece of material appears, it can be broken immediately to prevent the large piece of material from blocking the channel of the discharge valve.

A radially arranged crhing claw is installed on the rotor of the csher to move the block material through the grid and cru it.

The operation safety of the block cruing valve is guaranteed by the motor speed detection device integrated in the electric control box. When some block materials in the materials cannot be broken and jam the rotor, the speed detection device will alarm and automatically reverse, and push away the block materials that cannot be broken before forward rotation.

When the block material is too hard to be broken, the cruher will repeat forward and reverse rotation and alarm continuously. After the alarm, the operator shall remove these unbreakable blocks as soon as possible to avoid long-term forward and reverse rotation, resulting in equipment damage.

When the forward or reverse rotation is stuck, the cruser will stop automatically and wait for troubleshooting before operation.

The speed detection device is an optional device, which needs to be emphasized when ordering.

Characteristics of block cruher

• the flow of large models can reach 1000m3 / h

• suitable for all kinds of gasification chute and storage unloading outlet

• designed for material temperatures up to 120 degrees

• low energy consumption, only the driving motor power is 1.1KW (specifications below B400) and 1.5KW (specifications above B500) at 25 revolutions

• crusing claws and grid plates are made of high wear-resistant materials

• simple operation and maintenance