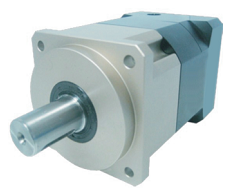

合肥行星齿轮减速机VRB-140-80-K3-38小间隙

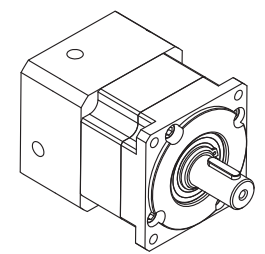

EAMON/伊明牌TVB/TVBR系列特點 TVB/TVBR Series Features

1.採用直齒齒輪傳動,經過滲碳淬火處理,齒向齒闊修行處理,表面噴砂鍍鎳,設備運行平穩,噪音小。

2.結構簡單,交貨期快,可大批量生產。

3.減速機種類齊全,滿足市場上大部分的應用工況。

1.Adopt spur gear transmission,after carburizing and quenching treatment,tooth to tooth wide practice treatment,surface sandblasting and nickel plating,stable operation of equipment,low noise.

2.Simple structure,fast delivery time,mass production.

3.There are a variety of reducer,which can meet most of the working conditions in the market.

合肥行星齿轮减速机VRB-140-80-K3-38小间隙

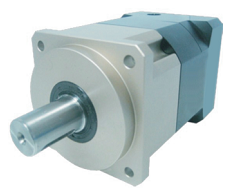

减速机安装时的八大注意有以下内容:1底座式安装,应校准中心线高度,联轴器连接时应校准两轴的同轴度;柔性联轴器时浮动量不超过联轴器的允许范围,刚性联接时必须保证各安装联接的形位公差;长轴联接还需轴的足够刚度。

2法兰式安装,凸肩(或凹肩)应配合良好,以免错位。法兰式安装并配空心轴联接时,特别应保证联接的形位公差。

3扭力臂安装,主动的空心轴与被动轴应配合良好,被动轴的浮动或设备振动应小于弹性块允许的范围,力臂应固定并锁紧。

4输出轴加状联轴器,皮带轮,齿轮,链轮等时,请勿重击,应用输出轴外端螺孔,联接件皮带轮,齿轮,链轮,搅拌式还需要考虑径向力。

合肥行星齿轮减速机VRB-140-80-K3-38小间隙

ABR60-H-003-004-005-006-007-008-010-015-020-P1

ABR60-H-025-030-035-040-050-060-070-080-100-P1

ABR60-H-003-004-005-006-007-008-010-015-020-P2

ABR60-H-025-030-035-040-050-060-070-080-100-P2

ABR90-H-003-004-005-006-007-008-010-015-020-P1

ABR90-H-025-030-035-040-050-060-070-080-100-P1

ABR90-H-003-004-005-006-007-008-010-015-020-P2

ABR90-H-025-030-035-040-050-060-070-080-100-P2

ABR060-H-003-004-005-006-007-008-010-015-020-P1

ABR060-H-025-030-035-040-050-060-070-080-100-P1

ABR060-H-003-004-005-006-007-008-010-015-020-P2

ABR060-H-025-030-035-040-050-060-070-080-100-P2

ABR090-H-003-004-005-006-007-008-010-015-020-P1

ABR090-H-025-030-035-040-050-060-070-080-100-P1

ABR090-H-003-004-005-006-007-008-010-015-020-P2

ABR090-H-025-030-035-040-050-060-070-080-100-P2

ABR115-H-003-004-005-006-007-008-010-015-020-P1

ABR115-H-025-030-035-040-050-060-070-080-100-P1

ABR115-H-003-004-005-006-007-008-010-015-020-P2

ABR115-H-025-030-035-040-050-060-070-080-100-P2

ABR142-H-003-004-005-006-007-008-010-015-020-P1

ABR142-H-025-030-035-040-050-060-070-080-100-P1

ABR142-H-003-004-005-006-007-008-010-015-020-P2

ABR142-H-025-030-035-040-050-060-070-080-100-P2

ABR180-H-003-004-005-006-007-008-010-015-020-P1

ABR180-H-025-030-035-040-050-060-070-080-100-P1

ABR180-H-003-004-005-006-007-008-010-015-020-P2

ABR180-H-025-030-035-040-050-060-070-080-100-P2

ABR220-H-003-004-005-006-007-008-010-015-020-P1

ABR220-H-025-030-035-040-050-060-070-080-100-P1

ABR220-H-003-004-005-006-007-008-010-015-020-P2

ABR220-H-025-030-035-040-050-060-070-080-100-P2

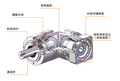

轴承的正确维护和保养方法:首先,锭子中的纺锭轴承在运转时,要充分保证润滑,并根据实际使用状况定期加润滑油,不可长时间断油。所以,对于用户企业来讲,应选用更好、更合适的锭子润滑油。新型专用锭子油可以显著地提高润滑性能,延长换油周期,延长锭子和轴承的使用寿命,还具有较好的防锈、防腐性能等。其次,采用增强尼龙材料保持架的轴承,使用温度应低于12℃,严禁油煮清洗。另外,锭子保养清洗时应注意方法,防止损坏、划伤滚柱表面。

合肥行星齿轮减速机VRB-140-80-K3-38小间隙