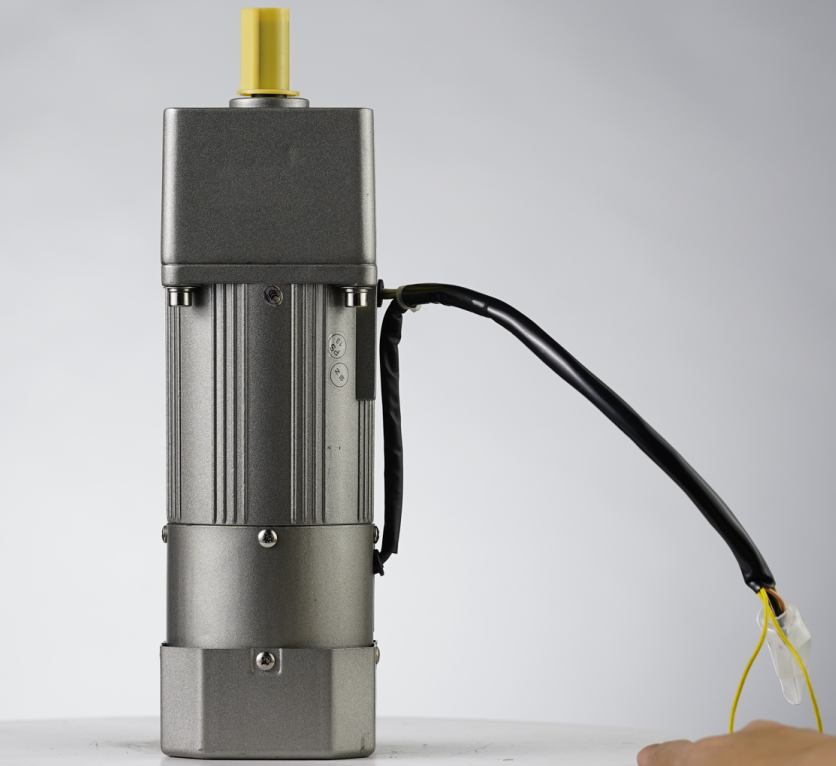

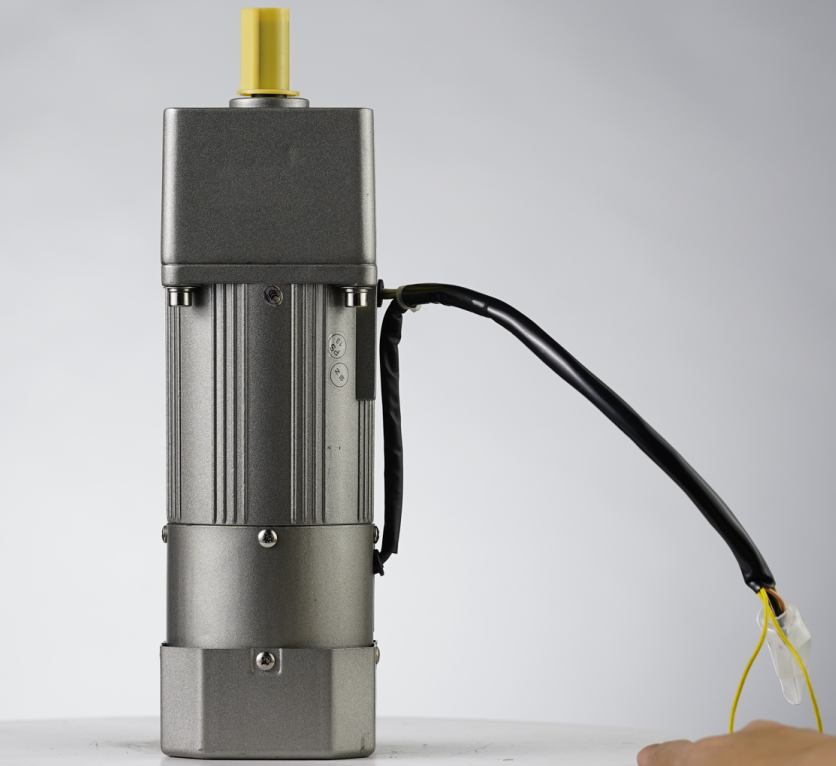

雹水乡厚利步进控制器9A7.5-05胶印机

厦门伊诗图电气有限公司

中国 厦门

产品属性

图文详情

品牌推荐

品牌

EASTOUR/伊诗图

型号

2IK-5IK

结构类型

其他

适用范围

工业用

励磁方式

他励式

机壳保护方式

防护式

加工定制

加工定制

额定功率

6-400W

额定电压

24-380V

额定转矩

1.0-15.9Nm

额定转速

90-3000r/minr/min

额定电流

0.4-10.3AA

效率

95%%

绝缘等级

666

防护等级

IP65

产品认证

888

外形尺寸

20*60*80mm

重量

8.5KGKg

直流电压

DC24V

交期电压

AC220-380V

直流功率

20W-400W

交流功率

6W-135W

减速比

1:3-1:360

雹水乡厚利步进控制器9A7.5-05胶印机

在热态安装时,应严格控制加热温度。加热轴承时,加热温度不得超过12C,一般应在8~1C。带防尘盖或密封圈的轴承不能加热,否则会造成润滑剂流失。加热方式可采用电感应佳人、油浴加热等方法。为选择最为合适的配合,必须考虑以下事项:载荷的方向;载荷的特性;载荷的大小;温度状况;安装与拆卸条件。关于KOYO轴承安装在薄壁轴承座孔中或空心轴上,则必须提供比正常情况要大的过盈配合。不推荐剖分式轴承座用于高精度或紧的座孔配合,否则剖分式轴承座可能引起外圈变形。

雹水乡厚利步进控制器9A7.5-05胶印机

2、定期检查油的份量和质量,保留足够润滑油,及时更换混入杂质或变质的油;

3、注油量须按表要求,不同牌号的油禁止混用、牌号相同而粘度不同的油允许混用;

4、注油量附表一、油品按附表二;

5、减速机工作环境温度为—40°C~+40°C,当环境温度低于0°C时,起动前润滑必须加热到0°C以上或采用低凝固点的润滑油。

五、NMRV蜗轮蜗杆减速机注意事项

1、不得重力锤击减速机外壳,以免损坏;

2、定期检修安装基础、密封件、传动轴等是否正常;

3、如正常使用时,润滑油的温度应小于85°C。油温温升变化异常,产生不正常噪声等现象时,应立即停机检查,排他故障后,主可继续使用;

4、更换新的备件必须经跑合和负载试验后再正式使用。

雹水乡厚利步进控制器9A7.5-05胶印机

雹水乡厚利步进控制器9A7.5-05胶印机

PW170-L1-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-001 -002

PW170-L2-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-003 -004

PW170-L2-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-005 -006

PW170-L2-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-008 -010

PW170-L3-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-009 -012

PW170-L3-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-015 -016

PW170-L3-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-020 -025

PW170-L3-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-030 -032

PW170-L3-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-040 -050

雹水乡厚利步进控制器9A7.5-05胶印机

随着全自动贴标机的大力投入到市场,在各大工厂都能看到它的影子,但是我们都知道一公分机械设备在使用过程中难免会出现故障,那么在平常的工作中如何处理一些常见故障呢?进瓶螺旋错位。出现这种情况的时候我们要用扳手将紧固螺栓松开,旋转螺旋调整到位置,先紧固一条螺栓,点动运行观察效果,位置合适后紧固其他螺栓;贴标标纸歪斜。这个时候我们要根据标纸在标板上的位置,调整标盒左右的高低;顶标撕标。如果出现这个问题我们要调整胶辊胶膜厚度;检查夹标指动作是否一致,予以调整。

CH400-3-S-B-G1-LD-H3

CH400-5-S-B-G1-LD-H3

CH400-10-S-B-G1-LD-H3

CH400-15-S-B-G1-LD-H3

CH400-20-S-B-G1-LD-H3

CH400-25-S-B-G1-LD-H3

CH400-30-S-B-G1-LD-H3

CH400-40-S-B-G1-LD-H3

CH400-45-S-B-G1-LD-H3

CH400-50-S-B-G1-LD-H3

CH400-60-S-B-G1-LD-H3

CH400-70-S-B-G1-LD-H3

CH400-80-S-B-G1-LD-H3

CH400-90-S-B-G1-LD-H3

CH400-100-S-B-G1-LD-H3

CH400-120-S-B-G1-LD-H3

CH400-140-S-B-G1-LD-H3

CH400-160-S-B-G1-LD-H3

CH400-180-S-B-G1-LD-H3

CH400-200-S-B-G1-LD-H3

CH750-3-S-B-G1-LD-H3

CH750-5-S-B-G1-LD-H3

CH750-10-S-B-G1-LD-H3

CH750-15-S-B-G1-LD-H3

CH750-20-S-B-G1-LD-H3

CH750-25-S-B-G1-LD-H3

CH750-30-S-B-G1-LD-H3

CH750-40-S-B-G1-LD-H3

CH750-45-S-B-G1-LD-H3

CH750-50-S-B-G1-LD-H3

CH750-60-S-B-G1-LD-H3

CH750-70-S-B-G1-LD-H3

CH750-80-S-B-G1-LD-H3

CH750-90-S-B-G1-LD-H3

CH750-100-S-B-G1-LD-H3

CH750-120-S-B-G1-LD-H3

CH750-140-S-B-G1-LD-H3

CH750-160-S-B-G1-LD-H3

CH750-180-S-B-G1-LD-H3

CH750-200-S-B-G1-LD-H3

CH1500-3-S-B-G1-LD-H3

CH1500-5-S-B-G1-LD-H3

CH1500-10-S-B-G1-LD-H3

CH1500-15-S-B-G1-LD-H3

CH1500-20-S-B-G1-LD-H3

CH1500-25-S-B-G1-LD-H3

CH1500-30-S-B-G1-LD-H3

CH1500-40-S-B-G1-LD-H3

CH1500-45-S-B-G1-LD-H3

CH1500-50-S-B-G1-LD-H3

CH1500-60-S-B-G1-LD-H3

CH1500-70-S-B-G1-LD-H3

CH1500-80-S-B-G1-LD-H3

CH1500-90-S-B-G1-LD-H3

CH1500-100-S-B-G1-LD-H3

CH1500-120-S-B-G1-LD-H3

CH1500-140-S-B-G1-LD-H3

CH1500-160-S-B-G1-LD-H3

CH1500-180-S-B-G1-LD-H3

CH1500-200-S-B-G1-LD-H3

CH2200-3-S-B-G1-LD-H3

CH2200-5-S-B-G1-LD-H3

CH2200-10-S-B-G1-LD-H3

CH2200-15-S-B-G1-LD-H3

CH2200-20-S-B-G1-LD-H3

CH2200-25-S-B-G1-LD-H3

CH2200-30-S-B-G1-LD-H3

CH2200-40-S-B-G1-LD-H3

CH2200-45-S-B-G1-LD-H3

CH2200-50-S-B-G1-LD-H3

CH2200-60-S-B-G1-LD-H3

CH2200-70-S-B-G1-LD-H3

CH2200-80-S-B-G1-LD-H3

CH2200-90-S-B-G1-LD-H3

CH2200-100-S-B-G1-LD-H3

CH2200-120-S-B-G1-LD-H3

CH2200-140-S-B-G1-LD-H3

CH2200-160-S-B-G1-LD-H3

CH2200-180-S-B-G1-LD-H3

CH2200-200-S-B-G1-LD-H3

在热态安装时,应严格控制加热温度。加热轴承时,加热温度不得超过12C,一般应在8~1C。带防尘盖或密封圈的轴承不能加热,否则会造成润滑剂流失。加热方式可采用电感应佳人、油浴加热等方法。为选择最为合适的配合,必须考虑以下事项:载荷的方向;载荷的特性;载荷的大小;温度状况;安装与拆卸条件。关于KOYO轴承安装在薄壁轴承座孔中或空心轴上,则必须提供比正常情况要大的过盈配合。不推荐剖分式轴承座用于高精度或紧的座孔配合,否则剖分式轴承座可能引起外圈变形。

雹水乡厚利步进控制器9A7.5-05胶印机

2、定期检查油的份量和质量,保留足够润滑油,及时更换混入杂质或变质的油;

3、注油量须按表要求,不同牌号的油禁止混用、牌号相同而粘度不同的油允许混用;

4、注油量附表一、油品按附表二;

5、减速机工作环境温度为—40°C~+40°C,当环境温度低于0°C时,起动前润滑必须加热到0°C以上或采用低凝固点的润滑油。

五、NMRV蜗轮蜗杆减速机注意事项

1、不得重力锤击减速机外壳,以免损坏;

2、定期检修安装基础、密封件、传动轴等是否正常;

3、如正常使用时,润滑油的温度应小于85°C。油温温升变化异常,产生不正常噪声等现象时,应立即停机检查,排他故障后,主可继续使用;

4、更换新的备件必须经跑合和负载试验后再正式使用。

雹水乡厚利步进控制器9A7.5-05胶印机

雹水乡厚利步进控制器9A7.5-05胶印机

PW170-L1-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-001 -002

PW170-L2-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-003 -004

PW170-L2-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-005 -006

PW170-L2-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-008 -010

PW170-L3-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-009 -012

PW170-L3-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-015 -016

PW170-L3-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-020 -025

PW170-L3-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-030 -032

PW170-L3-FL-FLM1-FML2-FL1-FL1M1 2-FH-FHM1 2-FC-FCM1 2-040 -050

雹水乡厚利步进控制器9A7.5-05胶印机

随着全自动贴标机的大力投入到市场,在各大工厂都能看到它的影子,但是我们都知道一公分机械设备在使用过程中难免会出现故障,那么在平常的工作中如何处理一些常见故障呢?进瓶螺旋错位。出现这种情况的时候我们要用扳手将紧固螺栓松开,旋转螺旋调整到位置,先紧固一条螺栓,点动运行观察效果,位置合适后紧固其他螺栓;贴标标纸歪斜。这个时候我们要根据标纸在标板上的位置,调整标盒左右的高低;顶标撕标。如果出现这个问题我们要调整胶辊胶膜厚度;检查夹标指动作是否一致,予以调整。

CH400-3-S-B-G1-LD-H3

CH400-5-S-B-G1-LD-H3

CH400-10-S-B-G1-LD-H3

CH400-15-S-B-G1-LD-H3

CH400-20-S-B-G1-LD-H3

CH400-25-S-B-G1-LD-H3

CH400-30-S-B-G1-LD-H3

CH400-40-S-B-G1-LD-H3

CH400-45-S-B-G1-LD-H3

CH400-50-S-B-G1-LD-H3

CH400-60-S-B-G1-LD-H3

CH400-70-S-B-G1-LD-H3

CH400-80-S-B-G1-LD-H3

CH400-90-S-B-G1-LD-H3

CH400-100-S-B-G1-LD-H3

CH400-120-S-B-G1-LD-H3

CH400-140-S-B-G1-LD-H3

CH400-160-S-B-G1-LD-H3

CH400-180-S-B-G1-LD-H3

CH400-200-S-B-G1-LD-H3

CH750-3-S-B-G1-LD-H3

CH750-5-S-B-G1-LD-H3

CH750-10-S-B-G1-LD-H3

CH750-15-S-B-G1-LD-H3

CH750-20-S-B-G1-LD-H3

CH750-25-S-B-G1-LD-H3

CH750-30-S-B-G1-LD-H3

CH750-40-S-B-G1-LD-H3

CH750-45-S-B-G1-LD-H3

CH750-50-S-B-G1-LD-H3

CH750-60-S-B-G1-LD-H3

CH750-70-S-B-G1-LD-H3

CH750-80-S-B-G1-LD-H3

CH750-90-S-B-G1-LD-H3

CH750-100-S-B-G1-LD-H3

CH750-120-S-B-G1-LD-H3

CH750-140-S-B-G1-LD-H3

CH750-160-S-B-G1-LD-H3

CH750-180-S-B-G1-LD-H3

CH750-200-S-B-G1-LD-H3

CH1500-3-S-B-G1-LD-H3

CH1500-5-S-B-G1-LD-H3

CH1500-10-S-B-G1-LD-H3

CH1500-15-S-B-G1-LD-H3

CH1500-20-S-B-G1-LD-H3

CH1500-25-S-B-G1-LD-H3

CH1500-30-S-B-G1-LD-H3

CH1500-40-S-B-G1-LD-H3

CH1500-45-S-B-G1-LD-H3

CH1500-50-S-B-G1-LD-H3

CH1500-60-S-B-G1-LD-H3

CH1500-70-S-B-G1-LD-H3

CH1500-80-S-B-G1-LD-H3

CH1500-90-S-B-G1-LD-H3

CH1500-100-S-B-G1-LD-H3

CH1500-120-S-B-G1-LD-H3

CH1500-140-S-B-G1-LD-H3

CH1500-160-S-B-G1-LD-H3

CH1500-180-S-B-G1-LD-H3

CH1500-200-S-B-G1-LD-H3

CH2200-3-S-B-G1-LD-H3

CH2200-5-S-B-G1-LD-H3

CH2200-10-S-B-G1-LD-H3

CH2200-15-S-B-G1-LD-H3

CH2200-20-S-B-G1-LD-H3

CH2200-25-S-B-G1-LD-H3

CH2200-30-S-B-G1-LD-H3

CH2200-40-S-B-G1-LD-H3

CH2200-45-S-B-G1-LD-H3

CH2200-50-S-B-G1-LD-H3

CH2200-60-S-B-G1-LD-H3

CH2200-70-S-B-G1-LD-H3

CH2200-80-S-B-G1-LD-H3

CH2200-90-S-B-G1-LD-H3

CH2200-100-S-B-G1-LD-H3

CH2200-120-S-B-G1-LD-H3

CH2200-140-S-B-G1-LD-H3

CH2200-160-S-B-G1-LD-H3

CH2200-180-S-B-G1-LD-H3

CH2200-200-S-B-G1-LD-H3