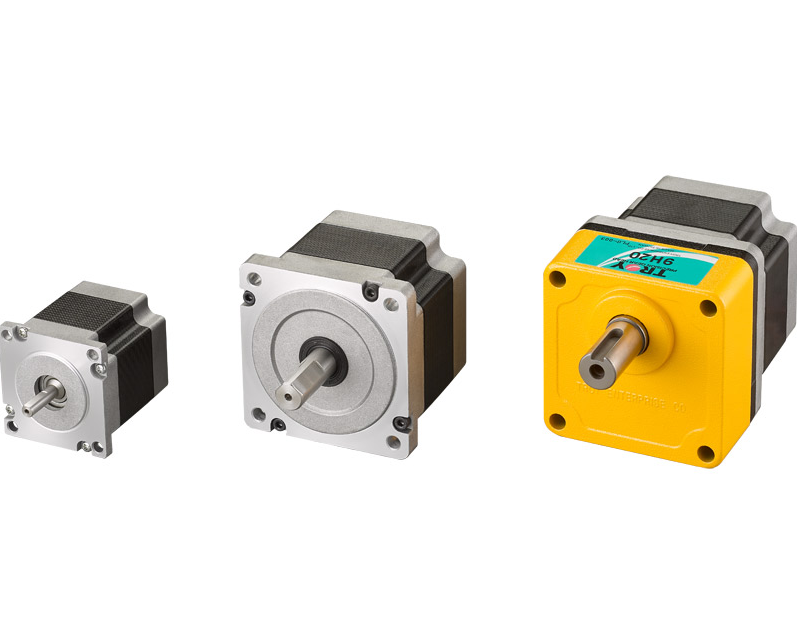

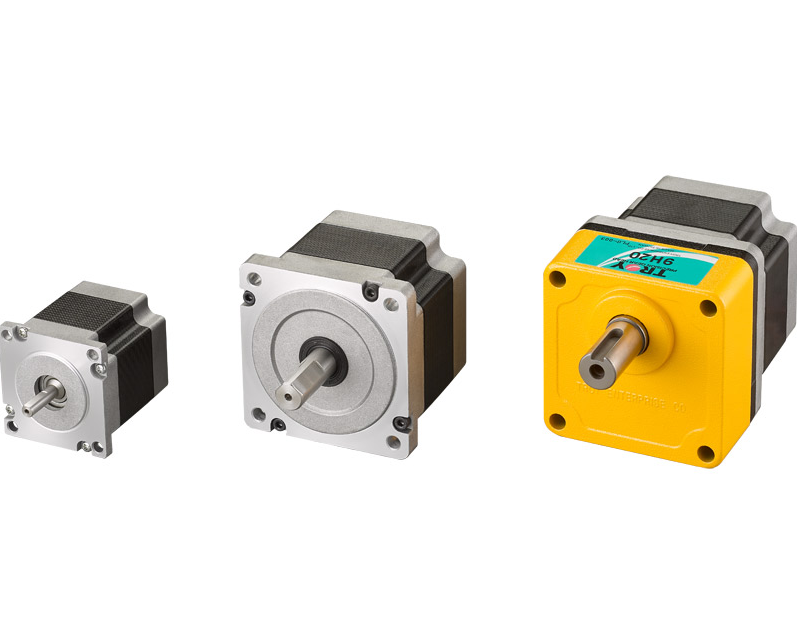

通化乡耐用智能TROY调速电机SBD020-1N斜齿轮

厦门伊诗图电气有限公司

中国 厦门

产品属性

图文详情

品牌推荐

品牌

EASTOUR/伊诗图

型号

2IK-5IK

结构类型

其他

适用范围

工业用

励磁方式

他励式

机壳保护方式

防护式

加工定制

加工定制

额定功率

6-400W

额定电压

24-380V

额定转矩

1.0-15.9Nm

额定转速

90-3000r/minr/min

额定电流

0.4-10.3AA

效率

95%%

绝缘等级

666

防护等级

IP65

产品认证

888

外形尺寸

20*60*80mm

重量

8.5KGKg

直流电压

DC24V

交期电压

AC220-380V

直流功率

20W-400W

交流功率

6W-135W

减速比

1:3-1:360

通化乡耐用智能TROY调速电机SBD020-1N斜齿轮

2.1.2 普通无刷直流电机

将有刷直流电机改为无刷直流电机,所不同的是定子为多相散嵌绕组,而转子为永磁磁极。这类电机转速设计的较低,一般不需减速机构,电机转速500~1000r/min。电机装于自行车的中轴上(习惯称中置电机)。由于采用无刷电机,因此这类电机通过驱动线路控制很容易实现调速。

2.1.3 印制绕组、线绕盘式直流电机

采用这两种电机的主要目的是利用这类电机薄饼式结构特点,使电机整体便于在自行车上合理安放。这类电机转速较高,3000~4000r/min,电机功率较大。本类电机需要与减速齿轮机构相配才能用于电动自行车上。线绕盘式直流电机由于其绕组参数便于调整,因此设计上可使电机特性有较大的变化,能适应多种负载特性要求。

通化乡耐用智能TROY调速电机SBD020-1N斜齿轮

这种材料的一个p-n脚可在热冷面之间产生约.2mV/K温差。图2:热电堆阵列和简单的TEG电气模型为了升高输出电压并获得更多的功率(参见图2),我们将许多脚电串联和热并联,以形成一个能够产生约25mV/K温差的热电堆。这种热能采集器可以建模为一个同电阻串联的电压源,其开路电压与温度差成比例关系。电阻来自于金属互连和芯块边缘的电阻。由此模型,我们可以很容易地知道,要想提取功能,就需要对阻抗进行控制,以匹配来自发电机的负载。

通化乡耐用智能TROY调速电机SBD020-1N斜齿轮

通化乡耐用智能TROY调速电机SBD020-1N斜齿轮

ZP70-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP70-60-80-100-120-125-150-160-200-256-320-P2

ZP90-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP90-60-80-100-120-125-150-160-200-256-320-P2

ZP115-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP115-60-80-100-120-125-150-160-200-256-320-P2

ZP142-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP142-60-80-100-120-125-150-160-200-256-320-P2

ZP190-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP190-60-80-100-120-125-150-160-200-256-320-P2

ZP240-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP240-60-80-100-120-125-150-160-200-256-320-P2

ZP285-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP285-60-80-100-120-125-150-160-200-256-320-P2

通化乡耐用智能TROY调速电机SBD020-1N斜齿轮

安装桶盖,最初的样子只是一块用橡木板拼接而成的方板。加工的时候,首先要找出桶盖的圆心,设定半径,用机器把多余的部分去掉,留下中间的圆形部分。检验和抛光,在两端的桶盖安装完毕以后,工人会在桶内注入水来测试橡木桶的精密度。万一出现漏水的情况,就要马上返工换橡木板或用特殊材料来把缝隙处理好。合格的橡木桶会被送到打磨机上打磨。外表变的光洁一新。并且安装上崭新的桶箍。这些桶箍将木板牢牢的固定在一起,并将伴随橡木桶的一生。

G12H400S-3; G12H400S-5; G12H400S-7.5; G12H400S-10; G12H400S-15; G12H400S-20; G12H400S-25; G12H400S-30; G12H400S-40; G12H400S-50; G12H400S-60; G12H400S-75; G12H400S-90;

G13H400S-50;G13H400S-60;G13H400S-75;G13H400S-90;G13H400S-100;G13H400S-120;G13H400S-150;G13H400S-165;G13H400S-180;

G14H400S-100;G14H400S-120;G14H400S-150;G14H400S-165;G14H400S-180;

G13H750S-3;G13H750S-5;G13H750S-10;G13H750S-15;G13H750S-20;G13H750S-25;G13H750S-30H40;G13H750S-50;G13H750S-60;G13H750S-75;G13H750S-90;

G14H750S-30;G14H750S-40;G14H750S-50;G14H750S-60;G14H750S-75;G14H750S-80;G14H750S-90;G14H750S-100; G14H750S-120;G14H750S-150;G14H750S-180;

G15H750S-80;G15H750S-100;G15H750S-120;G15H750S-150;G15H750S-200;

G14H1500S-3;G14H1500S-5;G14H1500S-10;G14H1500S-15;G14H1500S-20;G14H1500S-25;G14H1500S-30;G14H1500S-40;G14H1500S-50;G14H1500S-60;

G15H1500S-50;G15H1500S-60;G15H1500S-75;G15H1500S-80;G15H1500S-90;G15H1500S-100;

G14H2200S-3;G14H2200S-5;G14H2200S-10;G14H2200S-15;G14H2200S-20;G14H2200S-25;G14H2200S-30;G14H2200S-40;

G15H2200S-3;G15H2200S-5;G15H2200S-10;G15H2200S-15;G15H2200S-20;G15H2200S-25;G15H2200S-30;G15H2200S-40;G15H2200S-50;G15H2200S-60;G15H2200S-75;G15H2200S-80;G15H2200S-90;G15H2200S-100;

G11V100S-M3;G11V100S-M5;G11V100S-M10;G11V100S-M15;G11V100S-M20;G11V100S-M30;G11V100S-M40;G11V100S-M50; G11V100S-M60; G11V100S-M75;G11V100S-M90;

GE11V100S-M60; GE11V100S-M75;GE11V100S-M90;

G12V100S-M75; G12V100S-M90; G12V100S-M100;G12V100S-M120;G12V100S-M150; G12V100S-M165;

GE12V100S-M75;GE12V100S-M90;GE12V100S-M100;GE12V100S-M120;GE12V100S-M150;GE12V100S-M165;

G11V200S-M3; G11V200S-M5; G11V200S-M7.5; G11V200S-M10; G11V200S-M15; G11V200S-M20; G11V200S-M25; G11V200S-M30; G11V200S-M40; G11V200S-M50; G11V200S-M60;G11V200S-M75; G11V200S-M90;

GE11V200S-M50; GE11V200S-M60;GE11V200S-M75; GE11V200S-M90;

G12V200S-M20; G12V200S-M30; G12V200S-M40; G12V200S-M50; G12V200S-M60; G12V200S-M75; G12V200S-M80; G12V200S-M90; G12V200S-M100; G12V200S-M120; G12V200S-M150; G12V200S-M165;

GE12V200S-M100; GE12V200S-M120; GE12V200S-M150; GE12V200S-M165;

G13V200S-M100; G13V200S-M120; G13V200S-M150; G13V200S-M165; G13V200S-M180;

G12V400S-M3; G12V400S-M5; G12V400S-M7.5; G12V400S-M10; G12V400S-M15; G12V400S-M20; G12V400S-M25; G12V400S-M30; G12V400S-M40; G12V400S-M50; G12V400S-M60; G12V400S-M75; G12V400S-M90;

GE12V400S-M50; GE12V400S-M60; GE12V400S-M75; GE12V400S-M90;

G13V400S-M50;G13V400S-M60;G13V400S-M75;G13V400S-M90;G13V400S-M100;G13V400S-M120;G13V400S-M150;G13V400S-M165;G13V400S-M180;

G14V400S-M100;G14V400S-M120;G14V400S-M150;G14V400S-M165;G14V400S-M180;

2.1.2 普通无刷直流电机

将有刷直流电机改为无刷直流电机,所不同的是定子为多相散嵌绕组,而转子为永磁磁极。这类电机转速设计的较低,一般不需减速机构,电机转速500~1000r/min。电机装于自行车的中轴上(习惯称中置电机)。由于采用无刷电机,因此这类电机通过驱动线路控制很容易实现调速。

2.1.3 印制绕组、线绕盘式直流电机

采用这两种电机的主要目的是利用这类电机薄饼式结构特点,使电机整体便于在自行车上合理安放。这类电机转速较高,3000~4000r/min,电机功率较大。本类电机需要与减速齿轮机构相配才能用于电动自行车上。线绕盘式直流电机由于其绕组参数便于调整,因此设计上可使电机特性有较大的变化,能适应多种负载特性要求。

通化乡耐用智能TROY调速电机SBD020-1N斜齿轮

这种材料的一个p-n脚可在热冷面之间产生约.2mV/K温差。图2:热电堆阵列和简单的TEG电气模型为了升高输出电压并获得更多的功率(参见图2),我们将许多脚电串联和热并联,以形成一个能够产生约25mV/K温差的热电堆。这种热能采集器可以建模为一个同电阻串联的电压源,其开路电压与温度差成比例关系。电阻来自于金属互连和芯块边缘的电阻。由此模型,我们可以很容易地知道,要想提取功能,就需要对阻抗进行控制,以匹配来自发电机的负载。

通化乡耐用智能TROY调速电机SBD020-1N斜齿轮

通化乡耐用智能TROY调速电机SBD020-1N斜齿轮

ZP70-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP70-60-80-100-120-125-150-160-200-256-320-P2

ZP90-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP90-60-80-100-120-125-150-160-200-256-320-P2

ZP115-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP115-60-80-100-120-125-150-160-200-256-320-P2

ZP142-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP142-60-80-100-120-125-150-160-200-256-320-P2

ZP190-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP190-60-80-100-120-125-150-160-200-256-320-P2

ZP240-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP240-60-80-100-120-125-150-160-200-256-320-P2

ZP285-3-4-5-6-8-10-16-20-25-30-32-36-40-50-64-P2

ZP285-60-80-100-120-125-150-160-200-256-320-P2

通化乡耐用智能TROY调速电机SBD020-1N斜齿轮

安装桶盖,最初的样子只是一块用橡木板拼接而成的方板。加工的时候,首先要找出桶盖的圆心,设定半径,用机器把多余的部分去掉,留下中间的圆形部分。检验和抛光,在两端的桶盖安装完毕以后,工人会在桶内注入水来测试橡木桶的精密度。万一出现漏水的情况,就要马上返工换橡木板或用特殊材料来把缝隙处理好。合格的橡木桶会被送到打磨机上打磨。外表变的光洁一新。并且安装上崭新的桶箍。这些桶箍将木板牢牢的固定在一起,并将伴随橡木桶的一生。

G12H400S-3; G12H400S-5; G12H400S-7.5; G12H400S-10; G12H400S-15; G12H400S-20; G12H400S-25; G12H400S-30; G12H400S-40; G12H400S-50; G12H400S-60; G12H400S-75; G12H400S-90;

G13H400S-50;G13H400S-60;G13H400S-75;G13H400S-90;G13H400S-100;G13H400S-120;G13H400S-150;G13H400S-165;G13H400S-180;

G14H400S-100;G14H400S-120;G14H400S-150;G14H400S-165;G14H400S-180;

G13H750S-3;G13H750S-5;G13H750S-10;G13H750S-15;G13H750S-20;G13H750S-25;G13H750S-30H40;G13H750S-50;G13H750S-60;G13H750S-75;G13H750S-90;

G14H750S-30;G14H750S-40;G14H750S-50;G14H750S-60;G14H750S-75;G14H750S-80;G14H750S-90;G14H750S-100; G14H750S-120;G14H750S-150;G14H750S-180;

G15H750S-80;G15H750S-100;G15H750S-120;G15H750S-150;G15H750S-200;

G14H1500S-3;G14H1500S-5;G14H1500S-10;G14H1500S-15;G14H1500S-20;G14H1500S-25;G14H1500S-30;G14H1500S-40;G14H1500S-50;G14H1500S-60;

G15H1500S-50;G15H1500S-60;G15H1500S-75;G15H1500S-80;G15H1500S-90;G15H1500S-100;

G14H2200S-3;G14H2200S-5;G14H2200S-10;G14H2200S-15;G14H2200S-20;G14H2200S-25;G14H2200S-30;G14H2200S-40;

G15H2200S-3;G15H2200S-5;G15H2200S-10;G15H2200S-15;G15H2200S-20;G15H2200S-25;G15H2200S-30;G15H2200S-40;G15H2200S-50;G15H2200S-60;G15H2200S-75;G15H2200S-80;G15H2200S-90;G15H2200S-100;

G11V100S-M3;G11V100S-M5;G11V100S-M10;G11V100S-M15;G11V100S-M20;G11V100S-M30;G11V100S-M40;G11V100S-M50; G11V100S-M60; G11V100S-M75;G11V100S-M90;

GE11V100S-M60; GE11V100S-M75;GE11V100S-M90;

G12V100S-M75; G12V100S-M90; G12V100S-M100;G12V100S-M120;G12V100S-M150; G12V100S-M165;

GE12V100S-M75;GE12V100S-M90;GE12V100S-M100;GE12V100S-M120;GE12V100S-M150;GE12V100S-M165;

G11V200S-M3; G11V200S-M5; G11V200S-M7.5; G11V200S-M10; G11V200S-M15; G11V200S-M20; G11V200S-M25; G11V200S-M30; G11V200S-M40; G11V200S-M50; G11V200S-M60;G11V200S-M75; G11V200S-M90;

GE11V200S-M50; GE11V200S-M60;GE11V200S-M75; GE11V200S-M90;

G12V200S-M20; G12V200S-M30; G12V200S-M40; G12V200S-M50; G12V200S-M60; G12V200S-M75; G12V200S-M80; G12V200S-M90; G12V200S-M100; G12V200S-M120; G12V200S-M150; G12V200S-M165;

GE12V200S-M100; GE12V200S-M120; GE12V200S-M150; GE12V200S-M165;

G13V200S-M100; G13V200S-M120; G13V200S-M150; G13V200S-M165; G13V200S-M180;

G12V400S-M3; G12V400S-M5; G12V400S-M7.5; G12V400S-M10; G12V400S-M15; G12V400S-M20; G12V400S-M25; G12V400S-M30; G12V400S-M40; G12V400S-M50; G12V400S-M60; G12V400S-M75; G12V400S-M90;

GE12V400S-M50; GE12V400S-M60; GE12V400S-M75; GE12V400S-M90;

G13V400S-M50;G13V400S-M60;G13V400S-M75;G13V400S-M90;G13V400S-M100;G13V400S-M120;G13V400S-M150;G13V400S-M165;G13V400S-M180;

G14V400S-M100;G14V400S-M120;G14V400S-M150;G14V400S-M165;G14V400S-M180;