南岗街道TUNGLEE微型马达NRM040-020-0.4标签机

厦门伊诗图电气有限公司

中国 厦门

产品属性

图文详情

品牌推荐

品牌

/明椿

型号

NL-NF-CL-CF

结构类型

其他

适用范围

工业用

励磁方式

他励式

机壳保护方式

防护式

加工定制

加工定制

额定功率

6-400W

额定电压

24-380V

额定转矩

1.0-15.9Nm

额定转速

90-3000r/minr/min

额定电流

0.4-10.3AA

效率

95%%

绝缘等级

666

防护等级

IP65

产品认证

888

外形尺寸

20*60*80mm

重量

8.5KGKg

直流电压

DC24V

交期电压

AC220-380V

直流功率

20W-400W

交流功率

6W-135W

减速比

1:3-1:360

南岗街道TUNGLEE微型马达NRM040-020-0.4标签机

2、蜗轮磨损

蜗轮一般采用锡青铜,配对的蜗杆材料一般用45钢淬硬至HR5一55,还常用40C:淬硬HRC50一55,经蜗杆磨床磨削至粗糙度RaO.8fcm,减速机正常运行时,蜗杆就象一把淬硬的“锉刀”,不停地锉削蜗轮,使蜗轮产生磨损。一般来说,这种磨损很慢,象某厂有些减速机可以使用10年以上。如果磨损速度较快,就要考虑减速机的选型是否正确,是否有超负荷运行,蜗轮蜗杆的材质,装配质量或使用环境等原因。

3、传动小斜齿轮磨损

一般发生在立式安装的减速机上,主要跟润滑油的添加量和润滑油的选择有关。立式安装时,很容易造成润滑油油量不足,当减速机停止运转时,电机和减速机间传动齿轮油流失,齿轮得不到应有的润滑保护,启动或运转过程中得不到有效的润滑导致机械磨损甚至损坏。

4、蜗杆轴承损坏

减速机发生故障时,即使减速箱密封良好,该厂还是经常发现减速机内的齿轮油已经被乳化,轴承已生锈、腐蚀、损坏,这是因为减速机在运停过程中,齿轮油由热变冷后产生的水分凝聚造成;当然,也和轴承质量,装配工艺方法密切相关。

南岗街道TUNGLEE微型马达NRM040-020-0.4标签机

YDL080-3-P2

YDL080-4-P2

YDL080-5-P2

YDL080-7-P2

YDL080-10-P2

YDL080-16-P2

YDL080-20-P2

YDL080-25-P2

YDL080-28-P2

YDL080-35-P2

YDL080-40-P2

YDL080-50-P2

YDL080-70-P2

YDL080-100-P2

YDL090-3-P2

YDL090-4-P2

YDL090-5-P2

YDL090-7-P2

YDL090-10-P2

YDL090-16-P2

YDL090-20-P2

YDL090-25-P2

YDL090-28-P2

YDL090-35-P2

YDL090-40-P2

YDL090-50-P2

YDL090-70-P2

YDL090-100-P2

南岗街道TUNGLEE微型马达NRM040-020-0.4标签机

南岗街道TUNGLEE微型马达NRM040-020-0.4标签机

根据模具的变形规律预留加工余量,在淬火后不致于因为模具变形而使模具报废。对形状特别复杂的模具,为使淬火时冷却均匀,可采用组合结构。三.模具制造工序及残余应力的影响在工厂经常发现,一些形状复杂、精度要求高的模具,在热处理后变形较大,经认真调查后发现,模具在机械加工和最后热处理阶段未进行任何预先热处理。变形原因机械加工过程中的残余应力和淬火后的应力叠加,增大了模具热处理后的变形。预防措施粗加工后、半精加工前应进行一次去应力退火,即(63-68)℃(3-4)h炉冷至5℃以下出炉空冷,也可采用4℃(2-3)h去应力处理。

南岗街道TUNGLEE微型马达NRM040-020-0.4标签机

梅花扳手的两端具有带六角孔或十二角孔的工作端,适用于工作空间狭小,不能使用稍大扳手的场合。下面小编为大家介绍梅花扳手使用方法与注意事项是什么?一起来了解下吧。梅花扳手使用方法在使用梅花扳手时,左手推住梅花扳手与螺栓连接处,保持梅花扳手与螺栓完全配合,防止滑脱,右手握住梅花扳手另一端并加力。梅花扳手可将螺栓、螺母的头部全部围住,因此不会损坏螺栓角,可以施加大力矩。注意事项:扳转时,严禁将加长的管子套在扳手上以延伸扳手的长度增加力矩,严禁捶击扳手以增加力矩,否则会造成工具的损坏,严禁使用带有裂纹和内孔已严重磨损的梅花扳手。

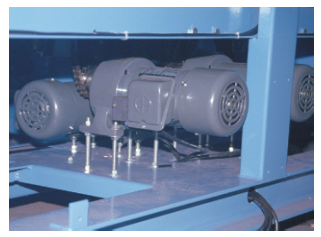

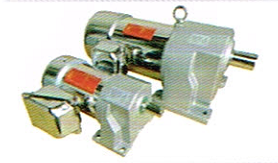

台湾SESAME世协刀库电机 G11V200S-M10 刹车马达G11V200S-M20

台湾SESAME世协刀库电机 G11V200S-M10 刹车马达G11V200S-M20

台湾SESAME刀库电机 G11V200S-M10 刹车马达

G11V100S-3;G11V100S-5;G11V100S-10;G11V100S-15;G11V100S-20;G11V100S-30;G11V100S-40;G11V100S-50; G11V100S-60; G11V100S-75;G11V100S-90;

GE11V100S-60; GE11V100S-75;GE11V100S-90;

G12V100S-75; G12V100S-90; G12V100S-100;G12V100S-120;G12V100S-150; G12V100S-165;

GE12V100S-75;GE12V100S-90;GE12V100S-100;GE12V100S-120;GE12V100S-150;GE12V100S-165;

G11V200S-3; G11V200S-5; G11V200S-7.5; G11V200S-10; G11V200S-15; G11V200S-20; G11V200S-25; G11V200S-30; G11V200S-40; G11V200S-50; G11V200S-60;G11V200S-75; G11V200S-90;

GE11V200S-50; GE11V200S-60;GE11V200S-75; GE11V200S-90;

G12V200S-20; G12V200S-30; G12V200S-40; G12V200S-50; G12V200S-60; G12V200S-75; G12V200S-80; G12V200S-90; G12V200S-100; G12V200S-120; G12V200S-150; G12V200S-165;

GE12V200S-100; GE12V200S-120; GE12V200S-150; GE12V200S-165;

G13V200S-100; G13V200S-120; G13V200S-150; G13V200S-165; G13V200S-180;

G12V400S-3; G12V400S-5; G12V400S-7.5; G12V400S-10; G12V400S-15; G12V400S-20; G12V400S-25; G12V400S-30; G12V400S-40; G12V400S-50; G12V400S-60; G12V400S-75; G12V400S-90;

GE12V400S-50; GE12V400S-60; GE12V400S-75; GE12V400S-90;

G13V400S-50;G13V400S-60;G13V400S-75;G13V400S-90;G13V400S-100;G13V400S-120;G13V400S-150;G13V400S-165;G13V400S-180;

G14V400S-100;G14V400S-120;G14V400S-150;G14V400S-165;G14V400S-180;

G13V750S-3;G13V750S-5;G13V750S-10;G13V750S-15;G13V750S-20;G13V750S-25;G13V750S-30V40;G13V750S-50;G13V750S-60;G13V750S-75;G13V750S-90;

G14V750S-30;G14V750S-40;G14V750S-50;G14V750S-60;G14V750S-75;G14V750S-80;G14V750S-90;G14V750S-100; G14V750S-120;G14V750S-150;G14V750S-180;

G15V750S-80;G15V750S-100;G15V750S-120;G15V750S-150;G15V750S-200;

G14V1500S-3;G14V1500S-5;G14V1500S-10;G14V1500S-15;G14V1500S-20;G14V1500S-25;G14V1500S-30;G14V1500S-40;G14V1500S-50;G14V1500S-60;

G15V1500S-50;G15V1500S-60;G15V1500S-75;G15V1500S-80;G15V1500S-90;G15V1500S-100;

G14V2200S-3;G14V2200S-5;G14V2200S-10;G14V2200S-15;G14V2200S-20;G14V2200S-25;G14V2200S-30;G14V2200S-40;

G15V2200S-3;G15V2200S-5;G15V2200S-10;G15V2200S-15;G15V2200S-20;G15V2200S-25;G15V2200S-30;G15V2200S-40;G15V2200S-50;G15V2200S-60;G15V2200S-75;G15V2200S-80;G15V2200S-90;G15V2200S-100;

台湾SESAME世协刀库电机 G11V200S-M10 刹车马达G11V200S-M20

台湾SESAME世协刀库电机 G11V200S-M10 刹车马达G11V200S-M20

2、蜗轮磨损

蜗轮一般采用锡青铜,配对的蜗杆材料一般用45钢淬硬至HR5一55,还常用40C:淬硬HRC50一55,经蜗杆磨床磨削至粗糙度RaO.8fcm,减速机正常运行时,蜗杆就象一把淬硬的“锉刀”,不停地锉削蜗轮,使蜗轮产生磨损。一般来说,这种磨损很慢,象某厂有些减速机可以使用10年以上。如果磨损速度较快,就要考虑减速机的选型是否正确,是否有超负荷运行,蜗轮蜗杆的材质,装配质量或使用环境等原因。

3、传动小斜齿轮磨损

一般发生在立式安装的减速机上,主要跟润滑油的添加量和润滑油的选择有关。立式安装时,很容易造成润滑油油量不足,当减速机停止运转时,电机和减速机间传动齿轮油流失,齿轮得不到应有的润滑保护,启动或运转过程中得不到有效的润滑导致机械磨损甚至损坏。

4、蜗杆轴承损坏

减速机发生故障时,即使减速箱密封良好,该厂还是经常发现减速机内的齿轮油已经被乳化,轴承已生锈、腐蚀、损坏,这是因为减速机在运停过程中,齿轮油由热变冷后产生的水分凝聚造成;当然,也和轴承质量,装配工艺方法密切相关。

南岗街道TUNGLEE微型马达NRM040-020-0.4标签机

YDL080-3-P2

YDL080-4-P2

YDL080-5-P2

YDL080-7-P2

YDL080-10-P2

YDL080-16-P2

YDL080-20-P2

YDL080-25-P2

YDL080-28-P2

YDL080-35-P2

YDL080-40-P2

YDL080-50-P2

YDL080-70-P2

YDL080-100-P2

YDL090-3-P2

YDL090-4-P2

YDL090-5-P2

YDL090-7-P2

YDL090-10-P2

YDL090-16-P2

YDL090-20-P2

YDL090-25-P2

YDL090-28-P2

YDL090-35-P2

YDL090-40-P2

YDL090-50-P2

YDL090-70-P2

YDL090-100-P2

南岗街道TUNGLEE微型马达NRM040-020-0.4标签机

南岗街道TUNGLEE微型马达NRM040-020-0.4标签机

根据模具的变形规律预留加工余量,在淬火后不致于因为模具变形而使模具报废。对形状特别复杂的模具,为使淬火时冷却均匀,可采用组合结构。三.模具制造工序及残余应力的影响在工厂经常发现,一些形状复杂、精度要求高的模具,在热处理后变形较大,经认真调查后发现,模具在机械加工和最后热处理阶段未进行任何预先热处理。变形原因机械加工过程中的残余应力和淬火后的应力叠加,增大了模具热处理后的变形。预防措施粗加工后、半精加工前应进行一次去应力退火,即(63-68)℃(3-4)h炉冷至5℃以下出炉空冷,也可采用4℃(2-3)h去应力处理。

南岗街道TUNGLEE微型马达NRM040-020-0.4标签机

梅花扳手的两端具有带六角孔或十二角孔的工作端,适用于工作空间狭小,不能使用稍大扳手的场合。下面小编为大家介绍梅花扳手使用方法与注意事项是什么?一起来了解下吧。梅花扳手使用方法在使用梅花扳手时,左手推住梅花扳手与螺栓连接处,保持梅花扳手与螺栓完全配合,防止滑脱,右手握住梅花扳手另一端并加力。梅花扳手可将螺栓、螺母的头部全部围住,因此不会损坏螺栓角,可以施加大力矩。注意事项:扳转时,严禁将加长的管子套在扳手上以延伸扳手的长度增加力矩,严禁捶击扳手以增加力矩,否则会造成工具的损坏,严禁使用带有裂纹和内孔已严重磨损的梅花扳手。

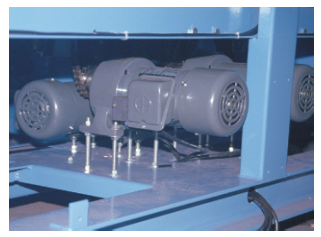

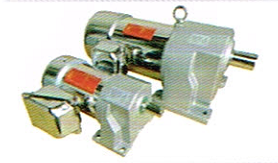

台湾SESAME世协刀库电机 G11V200S-M10 刹车马达G11V200S-M20

台湾SESAME世协刀库电机 G11V200S-M10 刹车马达G11V200S-M20

台湾SESAME刀库电机 G11V200S-M10 刹车马达

G11V100S-3;G11V100S-5;G11V100S-10;G11V100S-15;G11V100S-20;G11V100S-30;G11V100S-40;G11V100S-50; G11V100S-60; G11V100S-75;G11V100S-90;

GE11V100S-60; GE11V100S-75;GE11V100S-90;

G12V100S-75; G12V100S-90; G12V100S-100;G12V100S-120;G12V100S-150; G12V100S-165;

GE12V100S-75;GE12V100S-90;GE12V100S-100;GE12V100S-120;GE12V100S-150;GE12V100S-165;

G11V200S-3; G11V200S-5; G11V200S-7.5; G11V200S-10; G11V200S-15; G11V200S-20; G11V200S-25; G11V200S-30; G11V200S-40; G11V200S-50; G11V200S-60;G11V200S-75; G11V200S-90;

GE11V200S-50; GE11V200S-60;GE11V200S-75; GE11V200S-90;

G12V200S-20; G12V200S-30; G12V200S-40; G12V200S-50; G12V200S-60; G12V200S-75; G12V200S-80; G12V200S-90; G12V200S-100; G12V200S-120; G12V200S-150; G12V200S-165;

GE12V200S-100; GE12V200S-120; GE12V200S-150; GE12V200S-165;

G13V200S-100; G13V200S-120; G13V200S-150; G13V200S-165; G13V200S-180;

G12V400S-3; G12V400S-5; G12V400S-7.5; G12V400S-10; G12V400S-15; G12V400S-20; G12V400S-25; G12V400S-30; G12V400S-40; G12V400S-50; G12V400S-60; G12V400S-75; G12V400S-90;

GE12V400S-50; GE12V400S-60; GE12V400S-75; GE12V400S-90;

G13V400S-50;G13V400S-60;G13V400S-75;G13V400S-90;G13V400S-100;G13V400S-120;G13V400S-150;G13V400S-165;G13V400S-180;

G14V400S-100;G14V400S-120;G14V400S-150;G14V400S-165;G14V400S-180;

G13V750S-3;G13V750S-5;G13V750S-10;G13V750S-15;G13V750S-20;G13V750S-25;G13V750S-30V40;G13V750S-50;G13V750S-60;G13V750S-75;G13V750S-90;

G14V750S-30;G14V750S-40;G14V750S-50;G14V750S-60;G14V750S-75;G14V750S-80;G14V750S-90;G14V750S-100; G14V750S-120;G14V750S-150;G14V750S-180;

G15V750S-80;G15V750S-100;G15V750S-120;G15V750S-150;G15V750S-200;

G14V1500S-3;G14V1500S-5;G14V1500S-10;G14V1500S-15;G14V1500S-20;G14V1500S-25;G14V1500S-30;G14V1500S-40;G14V1500S-50;G14V1500S-60;

G15V1500S-50;G15V1500S-60;G15V1500S-75;G15V1500S-80;G15V1500S-90;G15V1500S-100;

G14V2200S-3;G14V2200S-5;G14V2200S-10;G14V2200S-15;G14V2200S-20;G14V2200S-25;G14V2200S-30;G14V2200S-40;

G15V2200S-3;G15V2200S-5;G15V2200S-10;G15V2200S-15;G15V2200S-20;G15V2200S-25;G15V2200S-30;G15V2200S-40;G15V2200S-50;G15V2200S-60;G15V2200S-75;G15V2200S-80;G15V2200S-90;G15V2200S-100;

台湾SESAME世协刀库电机 G11V200S-M10 刹车马达G11V200S-M20

台湾SESAME世协刀库电机 G11V200S-M10 刹车马达G11V200S-M20