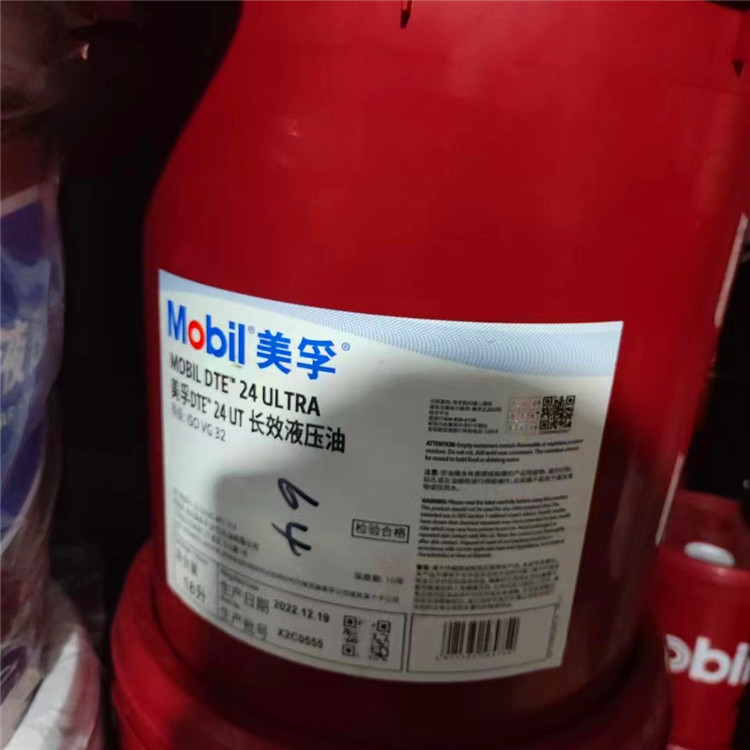

萍乡湘东区荷尧镇美孚液压油-导轨油经销拉

漳州市鑫富润商贸有限公司

中国 漳州

产品属性

图文详情

品牌推荐

品牌

美孚

型号

68

品种代号(L-)

HM

ISO粘度等级

46

特性

抗磨液压油

包装规格

208L

比重

088

运动粘度(40℃)

198mm2/s

粘度指数

1982

闪点(开口)

100号℃

倾点

-23℃

外观

液体

成分

矿物油

用途

液压系统