古堆乡压力传感器SM57ST51-0426B诚信共赢

厦门伊诗图电气有限公司

中国 厦门

产品属性

图文详情

品牌推荐

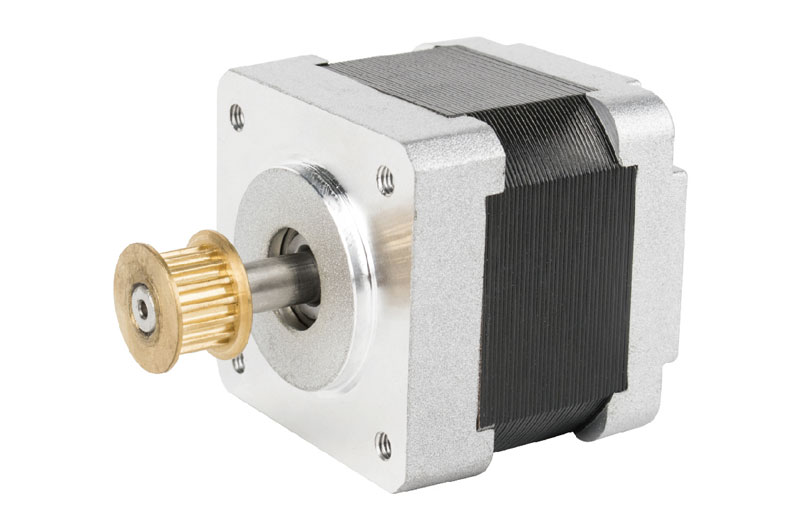

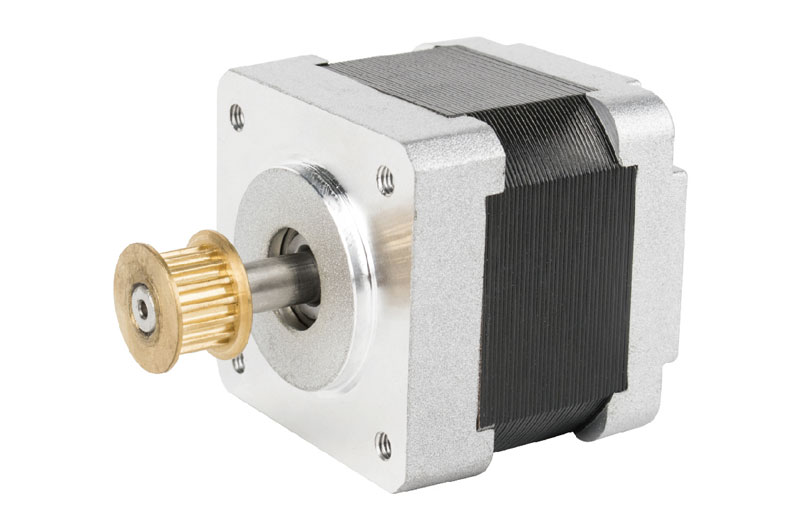

品牌

EASTOUR

型号

STEPPING MOTOR

结构类型

其他

适用范围

工业用

励磁方式

他励式

机壳保护方式

防护式

加工定制

加工定制

额定功率

6-400W

额定电压

24-380V

额定转矩

1.0-15.9Nm

额定转速

90-3000r/minr/min

额定电流

0.4-10.3AA

效率

95%%

绝缘等级

666

防护等级

IP65

产品认证

888

外形尺寸

20*60*80mm

重量

8.5KGKg

直流电压

DC24V

交期电压

AC220-380V

直流功率

20W-400W

交流功率

6W-135W

减速比

1:3-1:360

古堆乡压力传感器SM57ST51-0426B诚信共赢

造成直流伺服电动机转动不稳、振动的原因主要有以下几种: ①脉冲编码器不良。 ②电枢绕组不良,绕组内部短路或对地短路。 ③若在工作台快速移动时产生机床振动,甚至有较大的冲击或伺服单元的熔断器熔断时,故障的主要原因是测速发电机电刷接触不良。 (2)直流伺服电动机的维修 1)直流伺服电动机的基本检查。由于结构决定了直流伺服电动机的维修工作量要比交流伺服电动机大得多,当直流伺服电动机发生故障时,应进行如下检查: ①伺服电动机是否有机械损伤? ②电动机旋转部分是否可以手动正常转动? ③带制动器的伺服电动机,制动器是否可以正常松开? ④电动机是否有松动的螺钉或轴向间隙? ⑤电动机是否安装在潮湿、温度变化剧烈或有灰尘的地方? ⑥电动机是否长时间未开机?若如此,应将电刷从DC电动机上取出,重新清理换向器表面,因电刷长期停留在换向器的同一个位置,将引起换向器的生锈和腐蚀,从而使电动机换向不良和产生噪声。 ⑦电刷是否需要更换?若电刷剩下长度短于10mm,则电刷不能再使用,必须进行更换。若电刷接触面有任何深槽或伤痕,或在电刷弹簧上见到电弧痕迹,亦必须更换新电刷。更换时应用压缩空气吹去刷握中电刷粉尘,使用的压缩空气应不含铁粉和潮气。安装电刷时应拧紧刷帽,注意电刷弹簧不能夹在导电金属和刷握之间,并确认所有刷帽都拧到各自刷握同样的位置。电刷装入刷握时,应保证能平滑地移动,并使电刷表面与换向器表面良好吻合。 2)安装伺服电动机的注意点。

古堆乡压力传感器SM57ST51-0426B诚信共赢

日本轴承企业注重制造技术和工艺的开发。在代表团所访问的厂家中,企业均是高度自动化的生产和在线自动检测。但在生产线上,并非所有的设备都是进的,有的还是2世纪6或7年代的设备,但能和生产线结合在一起,并且能够保证产品质量,这得益于日本企业普遍重视生产技术的开发。代表团考察的企业大部分是生产厂,但技术开发部门都有较强的开发能力,在重视新产品开发的同时,同样注重生产技术和工艺的开发和创新,从而确保产品的质量。

ZH060-L1-2-P1-14-50-M4

ZH060-L1-3-P1-14-50-M4

ZH060-L1-5-P1-14-50-M4

ZH060-L2-10-P1-14-50-M4

ZH060-L2-12-P1-14-50-M4

ZH060-L2-15-P1-14-50-M4

ZH060-L2-20-P1-14-50-M4

ZH060-L2-25-P1-14-50-M4

ZH060-L2-30-P1-14-50-M4

ZH060-L2-35-P1-14-50-M4

ZH060-L2-50-P1-14-50-M4

ZH090-L1-2-P1-14-50-M4

ZH090-L1-3-P1-14-50-M4

ZH090-L1-5-P1-14-50-M4

ZH090-L2-10-P1-14-50-M4

ZH090-L2-12-P1-14-50-M4

ZH090-L2-15-P1-14-50-M4

ZH090-L2-20-P1-14-50-M4

ZH090-L2-25-P1-14-50-M4

ZH090-L2-30-P1-14-50-M4

ZH090-L2-35-P1-14-50-M4

ZH090-L2-50-P1-14-50-M4

古堆乡压力传感器SM57ST51-0426B诚信共赢

古堆乡压力传感器SM57ST51-0426B诚信共赢

转速过高会导致生产率下降及破碎机堵塞,特别是中、细碎圆锥破碎机,转速过高还会使物料因离心力增加而弹起,堵塞破碎腔。所以,一般不用增加转速的办法来增加生产率。规格大的破碎机,其动颚或动锥的调节行程也大,处理硬而脆的矿石要选取小的行程,软而粘的矿石应取大的行程。排矿口大寸固然生产率大,但破碎比下降,破碎作用减弱。排矿口很大时,大部分物料几乎未经破碎便排出来。排矿口很小时,虽然破碎比高,但生产率太低。故破碎机工作时,既要考虑破碎比,又要考虑生产率,二者兼顾,不能片面追求一个方面。

古堆乡压力传感器SM57ST51-0426B诚信共赢

G11H100S-3;G11H100S-5;G11H100S-10;G11H100S-15;G11H100S-20;G11H100S-30;G11H100S-40;G11H100S-50; G11H100S-60; G11H100S-75;G11H100S-90;

G12H100S-75; G12H100S-90; G12H100S-100;G12H100S-120;G12H100S-150; G12H100S-165;

G11H200S-3; G11H200S-5; G11H200S-7.5; G11H200S-10; G11H200S-15; G11H200S-20; G11H200S-25; G11H200S-30; G11H200S-40; G11H200S-50; G11H200S-60;G11H200S-75; G11H200S-90;

G12H200S-20; G12H200S-30; G12H200S-40; G12H200S-50; G12H200S-60; G12H200S-75; G12H200S-80; G12H200S-90; G12H200S-100; G12H200S-120; G12H200S-150; G12H200S-165;

G13H200S-100; G13H200S-120; G13H200S-150; G13H200S-165; G13H200S-180;

G12H400S-3; G12H400S-5; G12H400S-7.5; G12H400S-10; G12H400S-15; G12H400S-20; G12H400S-25; G12H400S-30; G12H400S-40; G12H400S-50; G12H400S-60; G12H400S-75; G12H400S-90;

G13H400S-50;G13H400S-60;G13H400S-75;G13H400S-90;G13H400S-100;G13H400S-120;G13H400S-150;G13H400S-165;G13H400S-180;

G14H400S-100;G14H400S-120;G14H400S-150;G14H400S-165;G14H400S-180;

G13H750S-3;G13H750S-5;G13H750S-10;G13H750S-15;G13H750S-20;G13H750S-25;G13H750S-30H40;G13H750S-50;G13H750S-60;G13H750S-75;G13H750S-90;

G14H750S-30;G14H750S-40;G14H750S-50;G14H750S-60;G14H750S-75;G14H750S-80;G14H750S-90;G14H750S-100; G14H750S-120;G14H750S-150;G14H750S-180;

G15H750S-80;G15H750S-100;G15H750S-120;G15H750S-150;G15H750S-200;

G14H1500S-3;G14H1500S-5;G14H1500S-10;G14H1500S-15;G14H1500S-20;G14H1500S-25;G14H1500S-30;G14H1500S-40;G14H1500S-50;G14H1500S-60;

G15H1500S-50;G15H1500S-60;G15H1500S-75;G15H1500S-80;G15H1500S-90;G15H1500S-100;

G14H2200S-3;G14H2200S-5;G14H2200S-10;G14H2200S-15;G14H2200S-20;G14H2200S-25;G14H2200S-30;G14H2200S-40;

G15H2200S-3;G15H2200S-5;G15H2200S-10;G15H2200S-15;G15H2200S-20;G15H2200S-25;G15H2200S-30;G15H2200S-40;G15H2200S-50;G15H2200S-60;G15H2200S-75;G15H2200S-80;G15H2200S-90;G15H2200S-100;

造成直流伺服电动机转动不稳、振动的原因主要有以下几种: ①脉冲编码器不良。 ②电枢绕组不良,绕组内部短路或对地短路。 ③若在工作台快速移动时产生机床振动,甚至有较大的冲击或伺服单元的熔断器熔断时,故障的主要原因是测速发电机电刷接触不良。 (2)直流伺服电动机的维修 1)直流伺服电动机的基本检查。由于结构决定了直流伺服电动机的维修工作量要比交流伺服电动机大得多,当直流伺服电动机发生故障时,应进行如下检查: ①伺服电动机是否有机械损伤? ②电动机旋转部分是否可以手动正常转动? ③带制动器的伺服电动机,制动器是否可以正常松开? ④电动机是否有松动的螺钉或轴向间隙? ⑤电动机是否安装在潮湿、温度变化剧烈或有灰尘的地方? ⑥电动机是否长时间未开机?若如此,应将电刷从DC电动机上取出,重新清理换向器表面,因电刷长期停留在换向器的同一个位置,将引起换向器的生锈和腐蚀,从而使电动机换向不良和产生噪声。 ⑦电刷是否需要更换?若电刷剩下长度短于10mm,则电刷不能再使用,必须进行更换。若电刷接触面有任何深槽或伤痕,或在电刷弹簧上见到电弧痕迹,亦必须更换新电刷。更换时应用压缩空气吹去刷握中电刷粉尘,使用的压缩空气应不含铁粉和潮气。安装电刷时应拧紧刷帽,注意电刷弹簧不能夹在导电金属和刷握之间,并确认所有刷帽都拧到各自刷握同样的位置。电刷装入刷握时,应保证能平滑地移动,并使电刷表面与换向器表面良好吻合。 2)安装伺服电动机的注意点。

古堆乡压力传感器SM57ST51-0426B诚信共赢

日本轴承企业注重制造技术和工艺的开发。在代表团所访问的厂家中,企业均是高度自动化的生产和在线自动检测。但在生产线上,并非所有的设备都是进的,有的还是2世纪6或7年代的设备,但能和生产线结合在一起,并且能够保证产品质量,这得益于日本企业普遍重视生产技术的开发。代表团考察的企业大部分是生产厂,但技术开发部门都有较强的开发能力,在重视新产品开发的同时,同样注重生产技术和工艺的开发和创新,从而确保产品的质量。

ZH060-L1-2-P1-14-50-M4

ZH060-L1-3-P1-14-50-M4

ZH060-L1-5-P1-14-50-M4

ZH060-L2-10-P1-14-50-M4

ZH060-L2-12-P1-14-50-M4

ZH060-L2-15-P1-14-50-M4

ZH060-L2-20-P1-14-50-M4

ZH060-L2-25-P1-14-50-M4

ZH060-L2-30-P1-14-50-M4

ZH060-L2-35-P1-14-50-M4

ZH060-L2-50-P1-14-50-M4

ZH090-L1-2-P1-14-50-M4

ZH090-L1-3-P1-14-50-M4

ZH090-L1-5-P1-14-50-M4

ZH090-L2-10-P1-14-50-M4

ZH090-L2-12-P1-14-50-M4

ZH090-L2-15-P1-14-50-M4

ZH090-L2-20-P1-14-50-M4

ZH090-L2-25-P1-14-50-M4

ZH090-L2-30-P1-14-50-M4

ZH090-L2-35-P1-14-50-M4

ZH090-L2-50-P1-14-50-M4

古堆乡压力传感器SM57ST51-0426B诚信共赢

古堆乡压力传感器SM57ST51-0426B诚信共赢

转速过高会导致生产率下降及破碎机堵塞,特别是中、细碎圆锥破碎机,转速过高还会使物料因离心力增加而弹起,堵塞破碎腔。所以,一般不用增加转速的办法来增加生产率。规格大的破碎机,其动颚或动锥的调节行程也大,处理硬而脆的矿石要选取小的行程,软而粘的矿石应取大的行程。排矿口大寸固然生产率大,但破碎比下降,破碎作用减弱。排矿口很大时,大部分物料几乎未经破碎便排出来。排矿口很小时,虽然破碎比高,但生产率太低。故破碎机工作时,既要考虑破碎比,又要考虑生产率,二者兼顾,不能片面追求一个方面。

古堆乡压力传感器SM57ST51-0426B诚信共赢

G11H100S-3;G11H100S-5;G11H100S-10;G11H100S-15;G11H100S-20;G11H100S-30;G11H100S-40;G11H100S-50; G11H100S-60; G11H100S-75;G11H100S-90;

G12H100S-75; G12H100S-90; G12H100S-100;G12H100S-120;G12H100S-150; G12H100S-165;

G11H200S-3; G11H200S-5; G11H200S-7.5; G11H200S-10; G11H200S-15; G11H200S-20; G11H200S-25; G11H200S-30; G11H200S-40; G11H200S-50; G11H200S-60;G11H200S-75; G11H200S-90;

G12H200S-20; G12H200S-30; G12H200S-40; G12H200S-50; G12H200S-60; G12H200S-75; G12H200S-80; G12H200S-90; G12H200S-100; G12H200S-120; G12H200S-150; G12H200S-165;

G13H200S-100; G13H200S-120; G13H200S-150; G13H200S-165; G13H200S-180;

G12H400S-3; G12H400S-5; G12H400S-7.5; G12H400S-10; G12H400S-15; G12H400S-20; G12H400S-25; G12H400S-30; G12H400S-40; G12H400S-50; G12H400S-60; G12H400S-75; G12H400S-90;

G13H400S-50;G13H400S-60;G13H400S-75;G13H400S-90;G13H400S-100;G13H400S-120;G13H400S-150;G13H400S-165;G13H400S-180;

G14H400S-100;G14H400S-120;G14H400S-150;G14H400S-165;G14H400S-180;

G13H750S-3;G13H750S-5;G13H750S-10;G13H750S-15;G13H750S-20;G13H750S-25;G13H750S-30H40;G13H750S-50;G13H750S-60;G13H750S-75;G13H750S-90;

G14H750S-30;G14H750S-40;G14H750S-50;G14H750S-60;G14H750S-75;G14H750S-80;G14H750S-90;G14H750S-100; G14H750S-120;G14H750S-150;G14H750S-180;

G15H750S-80;G15H750S-100;G15H750S-120;G15H750S-150;G15H750S-200;

G14H1500S-3;G14H1500S-5;G14H1500S-10;G14H1500S-15;G14H1500S-20;G14H1500S-25;G14H1500S-30;G14H1500S-40;G14H1500S-50;G14H1500S-60;

G15H1500S-50;G15H1500S-60;G15H1500S-75;G15H1500S-80;G15H1500S-90;G15H1500S-100;

G14H2200S-3;G14H2200S-5;G14H2200S-10;G14H2200S-15;G14H2200S-20;G14H2200S-25;G14H2200S-30;G14H2200S-40;

G15H2200S-3;G15H2200S-5;G15H2200S-10;G15H2200S-15;G15H2200S-20;G15H2200S-25;G15H2200S-30;G15H2200S-40;G15H2200S-50;G15H2200S-60;G15H2200S-75;G15H2200S-80;G15H2200S-90;G15H2200S-100;