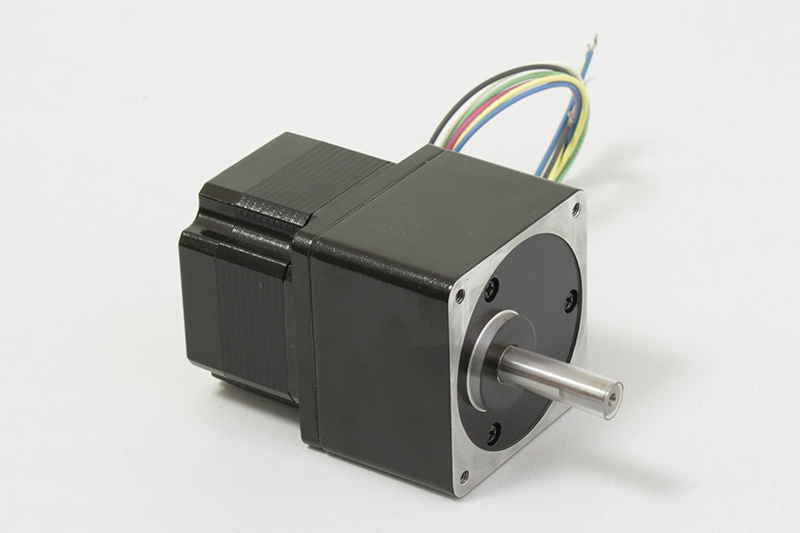

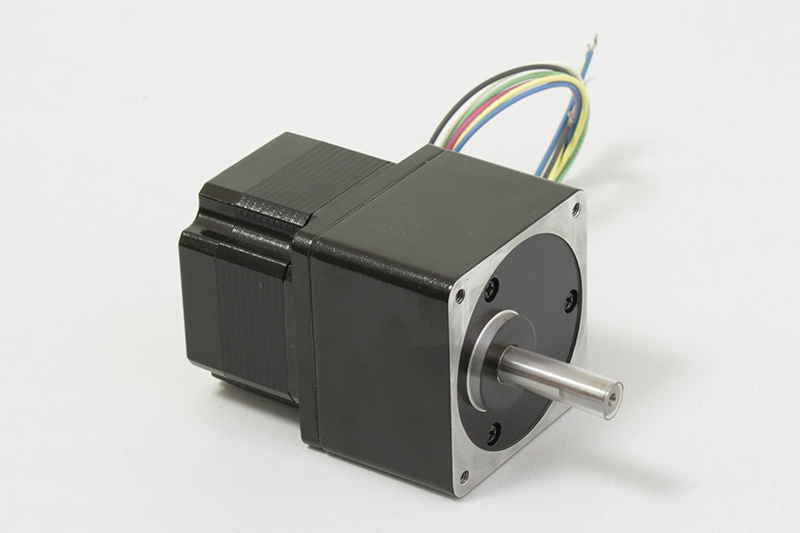

宝莲寺镇EASTOUR单相电机TQG减速电机US-2000-25W-220V

厦门伊诗图电气有限公司

中国 厦门

产品属性

图文详情

品牌推荐

品牌

EASTOUR

型号

STEPPING MOTOR

结构类型

其他

适用范围

工业用

励磁方式

他励式

机壳保护方式

防护式

加工定制

加工定制

额定功率

6-400W

额定电压

24-380V

额定转矩

1.0-15.9Nm

额定转速

90-3000r/minr/min

额定电流

0.4-10.3AA

效率

95%%

绝缘等级

666

防护等级

IP65

产品认证

888

外形尺寸

20*60*80mm

重量

8.5KGKg

直流电压

DC24V

交期电压

AC220-380V

直流功率

20W-400W

交流功率

6W-135W

减速比

1:3-1:360

宝莲寺镇EASTOUR单相电机TQG减速电机US-2000-25W-220V

步进电机失速可以通过以下方法来解决:

调整电流。如果步进电机失速是由于电流不足引起的,可以通过增加电流的方法来解决。要根据驱动器的类型和要求来选择合适的电流大小。调整电流之前,需要确认驱动器和电机的额定电流参数,并根据需要进行设置。

减小负载惯性。如果步进电机失速是由于负载惯性过大引起的,可以通过优化机械结构、减轻负载或重新组装来解决。

采用正确的驱动方式。选择适合步进电机的驱动方式也很重要。如果不确定驱动方式是否正确,可以咨询专业技术人员或参考驱动器的使用手册。

总之,解决步进电机失速需要针对具体原因进行相应的调整和优化,涉及电流调整、机械结构优化、驱动方式选择等多方面。在实际应用中,需要根据具体情况进行排查和解决。

调整驱动电流的方法主要依赖于拨码开关。可以根据实际需求,将拨码开关调整到相应的位置,以改变电流的大小。需要注意的是,调节电流的时候,电流只能比电机额定电流小,不可以比额定电流大,以防止对电机造成损害。

如果需要更地控制电流,可以使用电流表和可调电阻来手动调节。将电流表串入电机电源回路中,通过调节可调电阻来控制电流大小。这种方法需要一定的电子技术知识和设备,如果不确定如何操作,建议咨询专业技术人员。

总之,调整驱动电流需要根据具体情况选择合适的方法,并注意不要超过电机的额定电流,以保护电机和驱动器不受损害。

宝莲寺镇EASTOUR单相电机TQG减速电机US-2000-25W-220V

VS090-S-3-K-Z0

VS090-S-4-K-Z0

VS090-S-5-K-Z0

VS090-S-6-K-Z0

VS090-S-7-K-Z0

VS090-S-8-K-Z0

VS090-S-10-K-Z0

VS090-S-12-K-Z0

VS090-S-15-K-Z0

VS090-S-20-K-Z0

VS090-S-25-K-Z0

VS090-S-30-K-Z0

VS090-S-35-K-Z0

VS090-S-40-K-Z0

VS090-S-50-K-Z0

VS090-S-60-K-Z0

VS090-S-70-K-Z0

VS090-S-80-K-Z0

VS090-S-100-K-Z0

VS115-S-3-K-Z0

VS115-S-4-K-Z0

VS115-S-5-K-Z0

VS115-S-6-K-Z0

VS115-S-7-K-Z0

VS115-S-8-K-Z0

VS115-S-10-K-Z0

VS115-S-12-K-Z0

VS115-S-15-K-Z0

VS115-S-20-K-Z0

VS115-S-25-K-Z0

VS115-S-30-K-Z0

VS115-S-35-K-Z0

VS115-S-40-K-Z0

VS115-S-50-K-Z0

VS115-S-60-K-Z0

VS115-S-70-K-Z0

VS115-S-80-K-Z0

VS115-S-100-K-Z0

宝莲寺镇EASTOUR单相电机TQG减速电机US-2000-25W-220V

宝莲寺镇EASTOUR单相电机TQG减速电机US-2000-25W-220V

若在出力轴上安装链轮或皮带轮,并与链条或皮带配合后,也可当做像间歇性输送的输送带的在线型自动机器。摇摆装置:就是由入力轴做连续等速回转,而出力轴做往复式回转运动的装置。不仅能做单纯的往复式回转运动,而且还可做某一程度回转的中间位置、停止位置或回转角度的任意设置。罗拉装置:即为减速机,为得到无不均匀的回转及良好的回转和高转距,减速机是最加的选择方式。减速机除了可当减速应用之外,亦可当作分度盘最后从动件的任何分割或等。

宝莲寺镇EASTOUR单相电机TQG减速电机US-2000-25W-220V

拧紧时作顺时针转动手柄。方形的套筒上装有一只撑杆。当手柄向反方向扳回时,撑杆在棘轮齿的斜面中滑出,因而螺钉或螺母不会跟随反转。如果需要松开螺钉或螺母,只需翻转棘轮扳手朝逆时针方向转动即可。内六角扳手用于装拆内六角螺钉。常用于某些机电产品的拆装。测力扳手有一根长的弹性杆,其一端装着手柄,另一端装有方头或六角头,在方头或六角头套装一个可换的套筒用卡住。在顶端上还装有一个长指针。刻度板固定在柄座上,每格刻度值为1牛顿(或公斤/米)。

G11H100S-M3;G11H100S-M5;G11H100S-M10;G11H100S-M15;G11H100S-M20;G11H100S-M30;G11H100S-M40;G11H100S-M50; G11H100S-M60; G11H100S-M75;G11H100S-M90;

G12H100S-M75; G12H100S-M90; G12H100S-M100;G12H100S-M120;G12H100S-M150; G12H100S-M165;

G11H200S-M3; G11H200S-M5; G11H200S-M7.5; G11H200S-M10; G11H200S-M15; G11H200S-M20; G11H200S-M25; G11H200S-M30; G11H200S-M40; G11H200S-M50; G11H200S-M60;G11H200S-M75; G11H200S-M90;

G12H200S-M20; G12H200S-M30; G12H200S-M40; G12H200S-M50; G12H200S-M60; G12H200S-M75; G12H200S-M80; G12H200S-M90; G12H200S-M100; G12H200S-M120; G12H200S-M150; G12H200S-M165;

G13H200S-M100; G13H200S-M120; G13H200S-M150; G13H200S-M165; G13H200S-M180;

G12H400S-M3; G12H400S-M5; G12H400S-M7.5; G12H400S-M10; G12H400S-M15; G12H400S-M20; G12H400S-M25; G12H400S-M30; G12H400S-M40; G12H400S-M50; G12H400S-M60; G12H400S-M75; G12H400S-M90;

G13H400S-M50;G13H400S-M60;G13H400S-M75;G13H400S-M90;G13H400S-M100;G13H400S-M120;G13H400S-M150;G13H400S-M165;G13H400S-M180;

G14H400S-M100;G14H400S-M120;G14H400S-M150;G14H400S-M165;G14H400S-M180;

G13H750S-M3;G13H750S-M5;G13H750S-M10;G13H750S-M15;G13H750S-M20;G13H750S-M25;G13H750S-M30H40;G13H750S-M50;G13H750S-M60;G13H750S-M75;G13H750S-M90;

G14H750S-M30;G14H750S-M40;G14H750S-M50;G14H750S-M60;G14H750S-M75;G14H750S-M80;G14H750S-M90;G14H750S-M100; G14H750S-M120;G14H750S-M150;G14H750S-M180;

G15H750S-M80;G15H750S-M100;G15H750S-M120;G15H750S-M150;G15H750S-M200;

G14H1500S-M3;G14H1500S-M5;G14H1500S-M10;G14H1500S-M15;G14H1500S-M20;G14H1500S-M25;G14H1500S-M30;G14H1500S-M40;G14H1500S-M50;G14H1500S-M60;

G15H1500S-M50;G15H1500S-M60;G15H1500S-M75;G15H1500S-M80;G15H1500S-M90;G15H1500S-M100;

G14H2200S-M3;G14H2200S-M5;G14H2200S-M10;G14H2200S-M15;G14H2200S-M20;G14H2200S-M25;G14H2200S-M30;G14H2200S-M40;

G15H2200S-M3;G15H2200S-M5;G15H2200S-M10;G15H2200S-M15;G15H2200S-M20;G15H2200S-M25;G15H2200S-M30;G15H2200S-M40;G15H2200S-M50;G15H2200S-M60;G15H2200S-M75;G15H2200S-M80;G15H2200S-M90;G15H2200S-M100;

步进电机失速可以通过以下方法来解决:

调整电流。如果步进电机失速是由于电流不足引起的,可以通过增加电流的方法来解决。要根据驱动器的类型和要求来选择合适的电流大小。调整电流之前,需要确认驱动器和电机的额定电流参数,并根据需要进行设置。

减小负载惯性。如果步进电机失速是由于负载惯性过大引起的,可以通过优化机械结构、减轻负载或重新组装来解决。

采用正确的驱动方式。选择适合步进电机的驱动方式也很重要。如果不确定驱动方式是否正确,可以咨询专业技术人员或参考驱动器的使用手册。

总之,解决步进电机失速需要针对具体原因进行相应的调整和优化,涉及电流调整、机械结构优化、驱动方式选择等多方面。在实际应用中,需要根据具体情况进行排查和解决。

调整驱动电流的方法主要依赖于拨码开关。可以根据实际需求,将拨码开关调整到相应的位置,以改变电流的大小。需要注意的是,调节电流的时候,电流只能比电机额定电流小,不可以比额定电流大,以防止对电机造成损害。

如果需要更地控制电流,可以使用电流表和可调电阻来手动调节。将电流表串入电机电源回路中,通过调节可调电阻来控制电流大小。这种方法需要一定的电子技术知识和设备,如果不确定如何操作,建议咨询专业技术人员。

总之,调整驱动电流需要根据具体情况选择合适的方法,并注意不要超过电机的额定电流,以保护电机和驱动器不受损害。

宝莲寺镇EASTOUR单相电机TQG减速电机US-2000-25W-220V

VS090-S-3-K-Z0

VS090-S-4-K-Z0

VS090-S-5-K-Z0

VS090-S-6-K-Z0

VS090-S-7-K-Z0

VS090-S-8-K-Z0

VS090-S-10-K-Z0

VS090-S-12-K-Z0

VS090-S-15-K-Z0

VS090-S-20-K-Z0

VS090-S-25-K-Z0

VS090-S-30-K-Z0

VS090-S-35-K-Z0

VS090-S-40-K-Z0

VS090-S-50-K-Z0

VS090-S-60-K-Z0

VS090-S-70-K-Z0

VS090-S-80-K-Z0

VS090-S-100-K-Z0

VS115-S-3-K-Z0

VS115-S-4-K-Z0

VS115-S-5-K-Z0

VS115-S-6-K-Z0

VS115-S-7-K-Z0

VS115-S-8-K-Z0

VS115-S-10-K-Z0

VS115-S-12-K-Z0

VS115-S-15-K-Z0

VS115-S-20-K-Z0

VS115-S-25-K-Z0

VS115-S-30-K-Z0

VS115-S-35-K-Z0

VS115-S-40-K-Z0

VS115-S-50-K-Z0

VS115-S-60-K-Z0

VS115-S-70-K-Z0

VS115-S-80-K-Z0

VS115-S-100-K-Z0

宝莲寺镇EASTOUR单相电机TQG减速电机US-2000-25W-220V

宝莲寺镇EASTOUR单相电机TQG减速电机US-2000-25W-220V

若在出力轴上安装链轮或皮带轮,并与链条或皮带配合后,也可当做像间歇性输送的输送带的在线型自动机器。摇摆装置:就是由入力轴做连续等速回转,而出力轴做往复式回转运动的装置。不仅能做单纯的往复式回转运动,而且还可做某一程度回转的中间位置、停止位置或回转角度的任意设置。罗拉装置:即为减速机,为得到无不均匀的回转及良好的回转和高转距,减速机是最加的选择方式。减速机除了可当减速应用之外,亦可当作分度盘最后从动件的任何分割或等。

宝莲寺镇EASTOUR单相电机TQG减速电机US-2000-25W-220V

拧紧时作顺时针转动手柄。方形的套筒上装有一只撑杆。当手柄向反方向扳回时,撑杆在棘轮齿的斜面中滑出,因而螺钉或螺母不会跟随反转。如果需要松开螺钉或螺母,只需翻转棘轮扳手朝逆时针方向转动即可。内六角扳手用于装拆内六角螺钉。常用于某些机电产品的拆装。测力扳手有一根长的弹性杆,其一端装着手柄,另一端装有方头或六角头,在方头或六角头套装一个可换的套筒用卡住。在顶端上还装有一个长指针。刻度板固定在柄座上,每格刻度值为1牛顿(或公斤/米)。

G11H100S-M3;G11H100S-M5;G11H100S-M10;G11H100S-M15;G11H100S-M20;G11H100S-M30;G11H100S-M40;G11H100S-M50; G11H100S-M60; G11H100S-M75;G11H100S-M90;

G12H100S-M75; G12H100S-M90; G12H100S-M100;G12H100S-M120;G12H100S-M150; G12H100S-M165;

G11H200S-M3; G11H200S-M5; G11H200S-M7.5; G11H200S-M10; G11H200S-M15; G11H200S-M20; G11H200S-M25; G11H200S-M30; G11H200S-M40; G11H200S-M50; G11H200S-M60;G11H200S-M75; G11H200S-M90;

G12H200S-M20; G12H200S-M30; G12H200S-M40; G12H200S-M50; G12H200S-M60; G12H200S-M75; G12H200S-M80; G12H200S-M90; G12H200S-M100; G12H200S-M120; G12H200S-M150; G12H200S-M165;

G13H200S-M100; G13H200S-M120; G13H200S-M150; G13H200S-M165; G13H200S-M180;

G12H400S-M3; G12H400S-M5; G12H400S-M7.5; G12H400S-M10; G12H400S-M15; G12H400S-M20; G12H400S-M25; G12H400S-M30; G12H400S-M40; G12H400S-M50; G12H400S-M60; G12H400S-M75; G12H400S-M90;

G13H400S-M50;G13H400S-M60;G13H400S-M75;G13H400S-M90;G13H400S-M100;G13H400S-M120;G13H400S-M150;G13H400S-M165;G13H400S-M180;

G14H400S-M100;G14H400S-M120;G14H400S-M150;G14H400S-M165;G14H400S-M180;

G13H750S-M3;G13H750S-M5;G13H750S-M10;G13H750S-M15;G13H750S-M20;G13H750S-M25;G13H750S-M30H40;G13H750S-M50;G13H750S-M60;G13H750S-M75;G13H750S-M90;

G14H750S-M30;G14H750S-M40;G14H750S-M50;G14H750S-M60;G14H750S-M75;G14H750S-M80;G14H750S-M90;G14H750S-M100; G14H750S-M120;G14H750S-M150;G14H750S-M180;

G15H750S-M80;G15H750S-M100;G15H750S-M120;G15H750S-M150;G15H750S-M200;

G14H1500S-M3;G14H1500S-M5;G14H1500S-M10;G14H1500S-M15;G14H1500S-M20;G14H1500S-M25;G14H1500S-M30;G14H1500S-M40;G14H1500S-M50;G14H1500S-M60;

G15H1500S-M50;G15H1500S-M60;G15H1500S-M75;G15H1500S-M80;G15H1500S-M90;G15H1500S-M100;

G14H2200S-M3;G14H2200S-M5;G14H2200S-M10;G14H2200S-M15;G14H2200S-M20;G14H2200S-M25;G14H2200S-M30;G14H2200S-M40;

G15H2200S-M3;G15H2200S-M5;G15H2200S-M10;G15H2200S-M15;G15H2200S-M20;G15H2200S-M25;G15H2200S-M30;G15H2200S-M40;G15H2200S-M50;G15H2200S-M60;G15H2200S-M75;G15H2200S-M80;G15H2200S-M90;G15H2200S-M100;