产品介绍

- 产品信息

- 产品名称: 韩国工程塑料 POM F10-02

供货地区 |

| |||

性能特点 |

| |||

用途 |

| |||

RoHS 合规性 |

| |||

形式 |

| |||

加工方法 |

|

| 物理性能 | 额定值 | 单位制 | 测试方法 |

比重 | 1.41 | g/cm³ | ASTM D792,ISO 1183 |

熔流率 | |||

190°C/2.16 kg | 3.0 | g/10 min | ASTM D1238 |

-- | 3.0 | g/10 min | ISO 1133 |

收缩率 | |||

流动 : 3.00 mm | 2.2 | % | ASTM D955 |

3.00 mm | 2.2 | % | No Standard |

吸水率(平衡, 23°C, 60% RH) | 0.22 | % | ASTM D570 |

| 硬度 | 额定值 | 单位制 | 测试方法 |

洛氏硬度(M 计秤) | 78 |

| ASTM D785 |

| 机械性能 | 额定值 | 单位制 | 测试方法 |

抗张强度 | |||

屈服, 23°C | 60.3 | MPa | ASTM D638 |

屈服, 23°C | 63.0 | MPa | ISO 527-2 |

伸长率(断裂, 23°C) | 65 | % | ASTM D638 |

断张率(23°C) | 40 | % | ISO 527-2 |

弯曲模量 | |||

23°C | 2570 | MPa | ASTM D790 |

23°C | 2400 | MPa | ISO 178 |

弯曲强度 | |||

23°C | 88.0 | MPa | ASTM D790 |

23°C | 83.0 | MPa | ISO 178 |

剪切强度(2.00 mm) | 55.0 | MPa | ASTM D732 |

| 冲击性能 | 额定值 | 单位制 | 测试方法 |

简支梁缺口冲击强度 | 7.0 | kJ/m² | ISO 179/1eA |

悬壁梁缺口冲击强度(3.20 mm) | 69 | J/m | ASTM D256 |

| 热性能 | 额定值 | 单位制 | 测试方法 |

热变形温度 | |||

0.45 MPa, 未退火 | 158 | °C | ASTM D648 |

1.8 MPa, 未退火 | 110 | °C | ASTM D648 |

1.8 MPa, 未退火 | 96.0 | °C | ISO 75-2/A |

熔融温度 | 165 | °C | |

线形膨胀系数 - 流动(20 到 80°C) | 0.00013 | cm/cm/°C | ASTM D696 |

| 电气性能 | 额定值 | 单位制 | 测试方法 |

表面电阻率 | 1.0E+16 | ohm | ASTM D257,IEC 60093 |

体积电阻率 | 1.0E+14 | ohm·cm | ASTM D257,IEC 60093 |

介电强度 | 19 | kV/mm | ASTM D149,IEC 60243-1 |

介电常数(1 MHz) | 3.70 |

| ASTM D150 |

耗散因数(1 MHz) | 0.0070 |

| ASTM D150 |

| 可燃性 | 额定值 | 单位制 | 测试方法 |

UL 阻燃等级(0.800 mm) | HB |

| UL 94 |

GradesProcessingCharacteristicsClassificationNameHighviscosityF10-01

F10-02F10-03HMedium high viscosityF15-33Medium viscosityF20-03Medium low viscosityF25-03F25-03HLow viscosityF30-03Ultralow viscosityF40-03

| Extrusion (Rod,Sheet, Tube, Plate, Pipe) | - High toughness - Reduced porosity and white mark |

| Injection molding (Thick part) | - High stiffness |

| General injection molding (Medium meltflow rate between F10 and F20) | - High toughness - Proper for thick parts |

| General injection molding (Standard type) | - Standard and balanced property - Generalinjection molded parts |

| General injection molding (Medium meltflow rate between F20 and F30) | - Generalinjection molded parts |

| General injection molding (Medium meltflow rate between F20 and F30) | - High stiffness |

| General injection molding (Highmelt flow rate) | - Multi-cavities parts - Proper for thin and small shape parts |

| General injection molding (Ultra highmelt flow rate) | - Short cycle time - Proper for thin and small shape parts |

fiberfilledMF3025Glass bead filledFB2030Talcum filledTC3020WhiskerfilledFT2020

| General injection molding (Low content of glassfiber) | - High rigidity andhardness |

| General injection molding (Medium content of glassfiber) | - High stiffness and hardness |

| General injection molding (Highcontent of glassfiber) | - Highest stiffness,hardness and HDT - Reducedthermal expansion and shrinkage |

| General injection molding | - Minimizedsink mark andwarp - Reducedanisotropy |

| General injection molding | - Dimensional accuracy - Minimizedsink mark andwarp |

| General injection molding | - Dimensional stability |

| General injection molding | - Improvedstiffness - Dimensional stability |

(FU2015)TE-24

(FU2020)TE-25

(FU2025)TE-24S

| General injection molding ( Low wt% impact modifier) | - Improvedimpact strength and toughness - Reduced noiseand improved surface property |

| General injection molding (Mediumwt% impact modifier) | - High impact strength - Standardimpact modified grade |

| General injection molding (Highwt% impact modifier) | - Ultra high impactstrength - Flexibility |

| General injection molding (Conductivecarbon black filled) | - Conductive - GeneralType |

| General injection molding (Conductivecarbon black filled) | - Conductive - Improved fuel resistance and toughness |

| General injection molding (Carbonblack andcarbon fiber reinforced) | - Conductive - High stiffness and high creep strength |

| General injection molding (Ultra-low viscosityGrade) | - Anti-staticand reduction of noise - Preventionof dust adhesion |

| General injection molding and extrusion (High viscosityGrade) | - Static dissipative-Improvedimpact strength |

| General injection molding (Mediumviscosity) | - UV / light resistance(variouscolor) - Forinterior parts |

| General injection molding (Lowviscosity) | |

| General injection molding (Mediumviscosity) | - UV / light resistance(variousColor) - For lowgloss interior parts |

| General injection molding (Lowviscosity) | |

| General injection molding (Medium viscosity) | - Weatherand UV / light resistance(filledwith Carbon Black) - For interior and exterior parts |

| General injection molding (Lowviscosity) | |

| General injection molding (Mediumviscosity | - Weatherand UV / light resistance (filledwith Carbon Black) - For interior and exterior parts with improved impact strength |

FM2520SSpeciallubricantNX-20LO-21TX-21TX-31GR-30

| General injection molding (PTFEcontents: 20 %) | - High friction & wear resistance - Low specific wear rate |

| General injection molding (Lowcontents) | - High friction & wear resistance - HighPV limit value |

| General injection molding (Lowcontents) | - Highest friction & wear resistance - Highest PV limit value |

| General injection molding (High contents) | - Highest friction & wear resistance - For delaminationfreeand complicated part |

| General injection molding (MediumviscosityGrade) | - Low specific wearrate in condition of high load, low speed and against metal - For Bearing, bush parts |

| General injection molding (MediumviscosityGrade) | - High friction and wear resistance and reduced noise - Silicon free |

| General injection molding (MediumviscosityGrade) | - Highfrictionand wear resistance of plastics vs. metal |

| General injection molding (MediumviscosityGrade) | - High friction and wear resistance and reduced noise |

| General injection molding (LowviscosityGrade) | |

| General injection molding (LowviscosityGrade) | - Dimensionalstability and cutting process-ability - High frictionand wear resistance of plastics vs. metal |

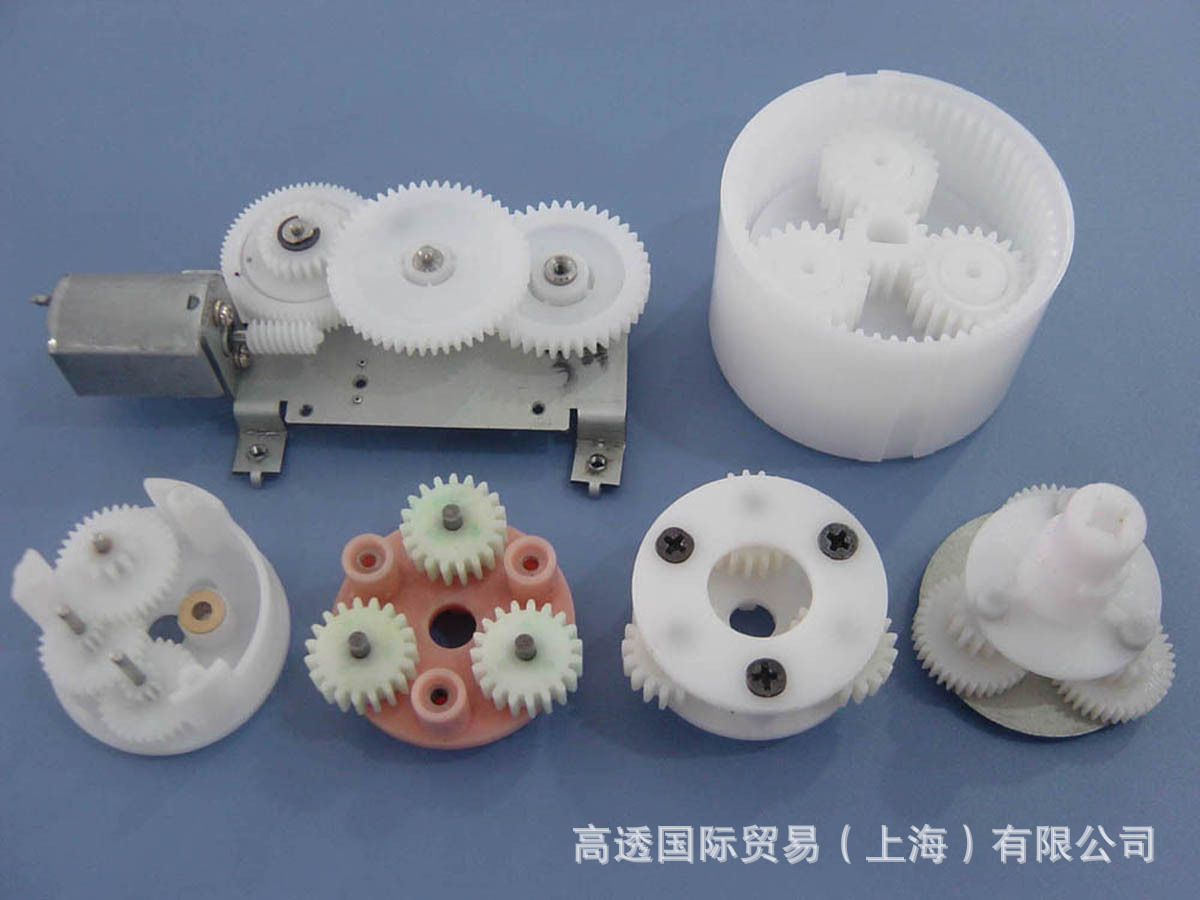

粒子图片

用途说明

库存图片

售后说明

1、物流运费说明

店铺报价不含运费,运费由买家承担,拍下付款后,买家可自行安排自己熟悉的物流上门提货,也可由卖家安排物流,运费提付(货送到后运费直接付给物流即可)。根据到货地址远近,及数量的多少,则运费不同。要货数量越多,运费越便宜。

2、在线下单

因塑胶行情价格波动较大,请用旺旺客服或电话直接询价确认后再拍。

- 3、在线支付

因塑胶行情价格波动较大,请拍下后当天内付款,不然不得不关闭交易喽~请体谅~ 4、退换货政策

到货后请买家仔细确认货物完好后再签收,否则如无质量问题,不退不换哦~

5、发票制度说明

本店既可以线下交易也可线上支付交易,已设置默认绑定的是公司账户支付宝,也可换绑私人卡支付宝,请拍前联系旺旺确认账户后再拍,谢谢啦~