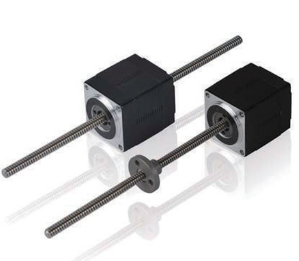

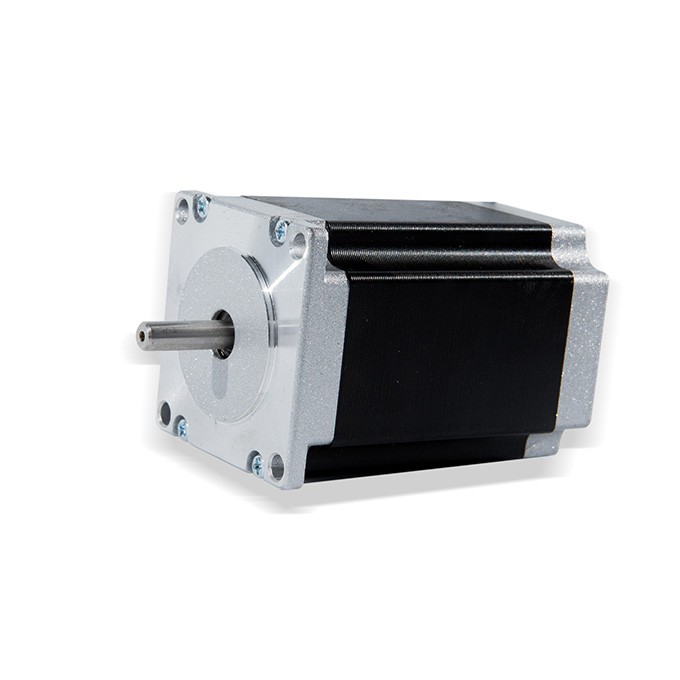

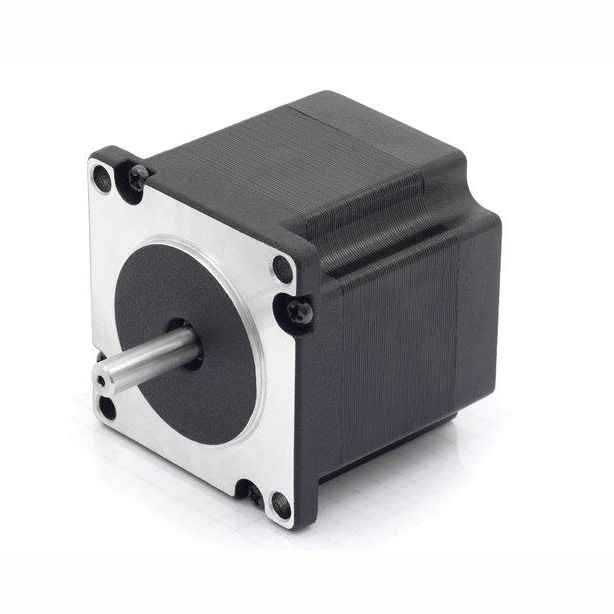

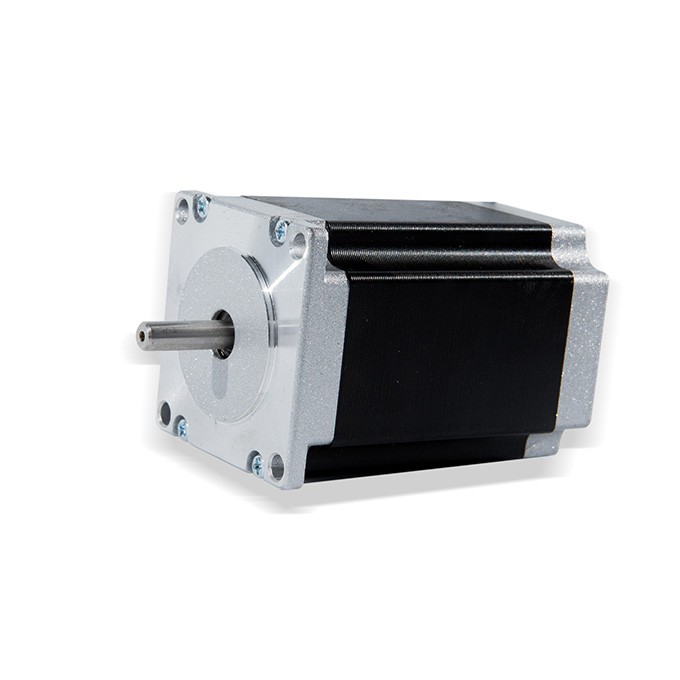

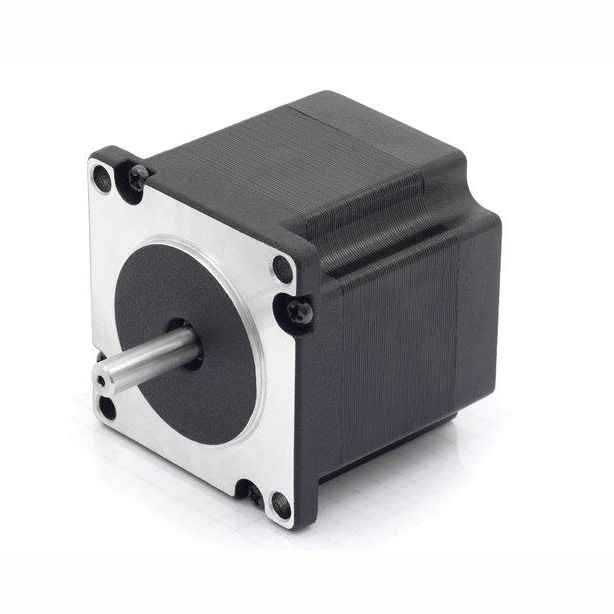

黄羊川镇42BYGH3630 2相直流电动机

厦门伊诗图电气有限公司

中国 厦门

产品属性

图文详情

品牌推荐

品牌

EASTOUR

型号

STEPPING MOTOR

结构类型

其他

适用范围

工业用

励磁方式

他励式

机壳保护方式

防护式

加工定制

加工定制

额定功率

6-400W

额定电压

24-380V

额定转矩

1.0-15.9Nm

额定转速

90-3000r/minr/min

额定电流

0.4-10.3AA

效率

95%%

绝缘等级

666

防护等级

IP65

产品认证

888

外形尺寸

20*60*80mm

重量

8.5KGKg

直流电压

DC24V

交期电压

AC220-380V

直流功率

20W-400W

交流功率

6W-135W

减速比

1:3-1:360

黄羊川镇42BYGH3630 2相直流电动机

1.安装前:先行确认购买齿轮减速电动机规格与设计规格是否相符?然后确认齿轮减速电动机外观是否破损,是否有漏油现象?再确认减速电机使用电压,电压不稳定时可加装稳压器。

2.着手安装:要确定固定机座,以避免运转传动时松脱。若使用链轮,皮带轮,联轴器等附件,需依照相关规定确实安装。

3.安装好后试运转:减速电机机体内已置入润滑黄油,12000小时免更换润滑油;减速电机传动运转时,额定电流不可超过马达铭牌标示电流值;请留意周边温度,湿度,酸碱度等问题;适应环境为-10度~+40度,湿度为90%以下,室内海拔1000公尺以下。

黄羊川镇42BYGH3630 2相直流电动机

调节阀口径的选择和确定主要依据阀的流通能力即Cv,从调节阀的Cv计算到阀的口径确定,一般需经以下步骤:计算流量的确定。现有的生产能力、设备负荷及介质的状况,决定计算流量的Qmax和Qmin.阀前后压差的确定。根据已选择的阀流量特性及系统特点选定S(阻力系数),再确定计算压差。计算Cv。根据所调节的介质选择合适的计算公式和图表,求得Cmax和Cmin选用Cv。根据Cmax,在所选择的产品标准系列中选取Cmax且与其最接近的一级Cv调节阀开度验算。

ZT065H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT065H-30-40-50-64-70-75-73.5-80-128-126

ZT075H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT075H-30-40-50-64-70-75-73.5-80-128-126

ZT090H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT090H-30-40-50-64-70-75-73.5-80-128-126

ZT110H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT110H-30-40-50-64-70-75-73.5-80-128-126

ZT140H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT140H-30-40-50-64-70-75-73.5-80-128-126

ZT170H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT170H-30-40-50-64-70-75-73.5-80-128-126

ZT210H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT210H-30-40-50-64-70-75-73.5-80-128-126

ZT240H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT240H-30-40-50-64-70-75-73.5-80-128-126

ZT65H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT65H-30-40-50-64-70-75-73.5-80-128-126

ZT75H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT75H-30-40-50-64-70-75-73.5-80-128-126

ZT90H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT90H-30-40-50-64-70-75-73.5-80-128-126

黄羊川镇42BYGH3630 2相直流电动机

黄羊川镇42BYGH3630 2相直流电动机

养护:丙乳砂浆抹压后约4h便产生终凝,此时用农用喷雾器进行喷雾养护。养护一天后在用毛刷在丙乳砂浆面层上一道丙乳净浆。要求涂匀、密封,待净浆产生终凝结硬后在继续喷雾养护。养护标准:砂浆面层始终保持潮湿状态,养护时间为7天。参考丙乳砂浆配合比。丙乳砂浆为灰砂比1∶1~1∶1.5灰乳比1∶.45~1∶.725丙乳净浆(涂层)为灰乳比2∶1丙乳砂浆的配制。按照配合比称料,分别堆放。先将水和丙乳混合均匀,水泥和砂混合均匀或倒入拌合盘中,然后将混合液慢慢倒入水泥和砂的混合物中人工拌合均匀,一次拌合量以水泥控制在1kg为宜。2ST-968防碳化涂料施工涂料的配制:防碳化涂料分为底层涂料和面层涂料两部分。底层涂料配制:底涂层材料为双组分,A组分为乳白色乳状液,B组分为灰色或微红色粉料,其配比为:A:B=1:1.8~2.2。面层涂料:面层涂料直接使用,使用前将涂料充分搅拌均匀。基层处理:由于在ST-968涂料施工前已经进行了丙乳砂浆的施工,所以ST-968的基层处理只需对潮湿带有露水的表面,先用抹布之类织物将表面露水擦干,然后再施工;对过干燥的表面,施工前在表面用喷雾器洒水,以保持混凝土表面适度湿润,保证涂层施工质量。

黄羊川镇42BYGH3630 2相直流电动机

CH3700-3-S-G4-DL-H0

CH3700-5-S-G4-DL-H0

CH3700-10-S-G4-DL-H0

CH3700-15-S-G4-DL-H0

CH3700-20-S-G4-DL-H0

CH3700-25-S-G4-DL-H0

CH3700-30-S-G4-DL-H0

CH3700-40-S-G4-DL-H0

CH3700-45-S-G4-DL-H0

CH3700-50-S-G4-DL-H0

CH3700-60-S-G4-DL-H0

CH3700-70-S-G4-DL-H0

CH3700-80-S-G4-DL-H0

CH3700-90-S-G4-DL-H0

CH3700-100-S-G4-DL-H0

CH3700-120-S-G4-DL-H0

CH3700-140-S-G4-DL-H0

CH3700-160-S-G4-DL-H0

CH3700-180-S-G4-DL-H0

CH3700-200-S-G4-DL-H0

CH100-3-S-B-G4-DL-H0

CH100-5-S-B-G4-DL-H0

CH100-10-S-B-G4-DL-H0

CH100-15-S-B-G4-DL-H0

CH100-20-S-B-G4-DL-H0

CH100-25-S-B-G4-DL-H0

CH100-30-S-B-G4-DL-H0

CH100-40-S-B-G4-DL-H0

CH100-45-S-B-G4-DL-H0

CH100-50-S-B-G4-DL-H0

CH100-60-S-B-G4-DL-H0

CH100-70-S-B-G4-DL-H0

CH100-80-S-B-G4-DL-H0

CH100-90-S-B-G4-DL-H0

CH100-100-S-B-G4-DL-H0

CH100-120-S-B-G4-DL-H0

CH100-140-S-B-G4-DL-H0

CH100-160-S-B-G4-DL-H0

CH100-180-S-B-G4-DL-H0

CH100-200-S-B-G4-DL-H0

CH200-3-S-B-G4-DL-H0

CH200-5-S-B-G4-DL-H0

CH200-10-S-B-G4-DL-H0

CH200-15-S-B-G4-DL-H0

CH200-20-S-B-G4-DL-H0

CH200-25-S-B-G4-DL-H0

CH200-30-S-B-G4-DL-H0

CH200-40-S-B-G4-DL-H0

CH200-45-S-B-G4-DL-H0

CH200-50-S-B-G4-DL-H0

CH200-60-S-B-G4-DL-H0

CH200-70-S-B-G4-DL-H0

CH200-80-S-B-G4-DL-H0

CH200-90-S-B-G4-DL-H0

CH200-100-S-B-G4-DL-H0

CH200-120-S-B-G4-DL-H0

CH200-140-S-B-G4-DL-H0

CH200-160-S-B-G4-DL-H0

CH200-180-S-B-G4-DL-H0

CH200-200-S-B-G4-DL-H0

CH400-3-S-B-G4-DL-H0

CH400-5-S-B-G4-DL-H0

CH400-10-S-B-G4-DL-H0

CH400-15-S-B-G4-DL-H0

CH400-20-S-B-G4-DL-H0

CH400-25-S-B-G4-DL-H0

CH400-30-S-B-G4-DL-H0

CH400-40-S-B-G4-DL-H0

CH400-45-S-B-G4-DL-H0

CH400-50-S-B-G4-DL-H0

CH400-60-S-B-G4-DL-H0

CH400-70-S-B-G4-DL-H0

CH400-80-S-B-G4-DL-H0

CH400-90-S-B-G4-DL-H0

CH400-100-S-B-G4-DL-H0

CH400-120-S-B-G4-DL-H0

CH400-140-S-B-G4-DL-H0

CH400-160-S-B-G4-DL-H0

CH400-180-S-B-G4-DL-H0

CH400-200-S-B-G4-DL-H0

1.安装前:先行确认购买齿轮减速电动机规格与设计规格是否相符?然后确认齿轮减速电动机外观是否破损,是否有漏油现象?再确认减速电机使用电压,电压不稳定时可加装稳压器。

2.着手安装:要确定固定机座,以避免运转传动时松脱。若使用链轮,皮带轮,联轴器等附件,需依照相关规定确实安装。

3.安装好后试运转:减速电机机体内已置入润滑黄油,12000小时免更换润滑油;减速电机传动运转时,额定电流不可超过马达铭牌标示电流值;请留意周边温度,湿度,酸碱度等问题;适应环境为-10度~+40度,湿度为90%以下,室内海拔1000公尺以下。

黄羊川镇42BYGH3630 2相直流电动机

调节阀口径的选择和确定主要依据阀的流通能力即Cv,从调节阀的Cv计算到阀的口径确定,一般需经以下步骤:计算流量的确定。现有的生产能力、设备负荷及介质的状况,决定计算流量的Qmax和Qmin.阀前后压差的确定。根据已选择的阀流量特性及系统特点选定S(阻力系数),再确定计算压差。计算Cv。根据所调节的介质选择合适的计算公式和图表,求得Cmax和Cmin选用Cv。根据Cmax,在所选择的产品标准系列中选取Cmax且与其最接近的一级Cv调节阀开度验算。

ZT065H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT065H-30-40-50-64-70-75-73.5-80-128-126

ZT075H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT075H-30-40-50-64-70-75-73.5-80-128-126

ZT090H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT090H-30-40-50-64-70-75-73.5-80-128-126

ZT110H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT110H-30-40-50-64-70-75-73.5-80-128-126

ZT140H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT140H-30-40-50-64-70-75-73.5-80-128-126

ZT170H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT170H-30-40-50-64-70-75-73.5-80-128-126

ZT210H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT210H-30-40-50-64-70-75-73.5-80-128-126

ZT240H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT240H-30-40-50-64-70-75-73.5-80-128-126

ZT65H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT65H-30-40-50-64-70-75-73.5-80-128-126

ZT75H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT75H-30-40-50-64-70-75-73.5-80-128-126

ZT90H-1-1.5-2-3-4-6-8-10-14-16-18-20-24

ZT90H-30-40-50-64-70-75-73.5-80-128-126

黄羊川镇42BYGH3630 2相直流电动机

黄羊川镇42BYGH3630 2相直流电动机

养护:丙乳砂浆抹压后约4h便产生终凝,此时用农用喷雾器进行喷雾养护。养护一天后在用毛刷在丙乳砂浆面层上一道丙乳净浆。要求涂匀、密封,待净浆产生终凝结硬后在继续喷雾养护。养护标准:砂浆面层始终保持潮湿状态,养护时间为7天。参考丙乳砂浆配合比。丙乳砂浆为灰砂比1∶1~1∶1.5灰乳比1∶.45~1∶.725丙乳净浆(涂层)为灰乳比2∶1丙乳砂浆的配制。按照配合比称料,分别堆放。先将水和丙乳混合均匀,水泥和砂混合均匀或倒入拌合盘中,然后将混合液慢慢倒入水泥和砂的混合物中人工拌合均匀,一次拌合量以水泥控制在1kg为宜。2ST-968防碳化涂料施工涂料的配制:防碳化涂料分为底层涂料和面层涂料两部分。底层涂料配制:底涂层材料为双组分,A组分为乳白色乳状液,B组分为灰色或微红色粉料,其配比为:A:B=1:1.8~2.2。面层涂料:面层涂料直接使用,使用前将涂料充分搅拌均匀。基层处理:由于在ST-968涂料施工前已经进行了丙乳砂浆的施工,所以ST-968的基层处理只需对潮湿带有露水的表面,先用抹布之类织物将表面露水擦干,然后再施工;对过干燥的表面,施工前在表面用喷雾器洒水,以保持混凝土表面适度湿润,保证涂层施工质量。

黄羊川镇42BYGH3630 2相直流电动机

CH3700-3-S-G4-DL-H0

CH3700-5-S-G4-DL-H0

CH3700-10-S-G4-DL-H0

CH3700-15-S-G4-DL-H0

CH3700-20-S-G4-DL-H0

CH3700-25-S-G4-DL-H0

CH3700-30-S-G4-DL-H0

CH3700-40-S-G4-DL-H0

CH3700-45-S-G4-DL-H0

CH3700-50-S-G4-DL-H0

CH3700-60-S-G4-DL-H0

CH3700-70-S-G4-DL-H0

CH3700-80-S-G4-DL-H0

CH3700-90-S-G4-DL-H0

CH3700-100-S-G4-DL-H0

CH3700-120-S-G4-DL-H0

CH3700-140-S-G4-DL-H0

CH3700-160-S-G4-DL-H0

CH3700-180-S-G4-DL-H0

CH3700-200-S-G4-DL-H0

CH100-3-S-B-G4-DL-H0

CH100-5-S-B-G4-DL-H0

CH100-10-S-B-G4-DL-H0

CH100-15-S-B-G4-DL-H0

CH100-20-S-B-G4-DL-H0

CH100-25-S-B-G4-DL-H0

CH100-30-S-B-G4-DL-H0

CH100-40-S-B-G4-DL-H0

CH100-45-S-B-G4-DL-H0

CH100-50-S-B-G4-DL-H0

CH100-60-S-B-G4-DL-H0

CH100-70-S-B-G4-DL-H0

CH100-80-S-B-G4-DL-H0

CH100-90-S-B-G4-DL-H0

CH100-100-S-B-G4-DL-H0

CH100-120-S-B-G4-DL-H0

CH100-140-S-B-G4-DL-H0

CH100-160-S-B-G4-DL-H0

CH100-180-S-B-G4-DL-H0

CH100-200-S-B-G4-DL-H0

CH200-3-S-B-G4-DL-H0

CH200-5-S-B-G4-DL-H0

CH200-10-S-B-G4-DL-H0

CH200-15-S-B-G4-DL-H0

CH200-20-S-B-G4-DL-H0

CH200-25-S-B-G4-DL-H0

CH200-30-S-B-G4-DL-H0

CH200-40-S-B-G4-DL-H0

CH200-45-S-B-G4-DL-H0

CH200-50-S-B-G4-DL-H0

CH200-60-S-B-G4-DL-H0

CH200-70-S-B-G4-DL-H0

CH200-80-S-B-G4-DL-H0

CH200-90-S-B-G4-DL-H0

CH200-100-S-B-G4-DL-H0

CH200-120-S-B-G4-DL-H0

CH200-140-S-B-G4-DL-H0

CH200-160-S-B-G4-DL-H0

CH200-180-S-B-G4-DL-H0

CH200-200-S-B-G4-DL-H0

CH400-3-S-B-G4-DL-H0

CH400-5-S-B-G4-DL-H0

CH400-10-S-B-G4-DL-H0

CH400-15-S-B-G4-DL-H0

CH400-20-S-B-G4-DL-H0

CH400-25-S-B-G4-DL-H0

CH400-30-S-B-G4-DL-H0

CH400-40-S-B-G4-DL-H0

CH400-45-S-B-G4-DL-H0

CH400-50-S-B-G4-DL-H0

CH400-60-S-B-G4-DL-H0

CH400-70-S-B-G4-DL-H0

CH400-80-S-B-G4-DL-H0

CH400-90-S-B-G4-DL-H0

CH400-100-S-B-G4-DL-H0

CH400-120-S-B-G4-DL-H0

CH400-140-S-B-G4-DL-H0

CH400-160-S-B-G4-DL-H0

CH400-180-S-B-G4-DL-H0

CH400-200-S-B-G4-DL-H0