introduction to POK:

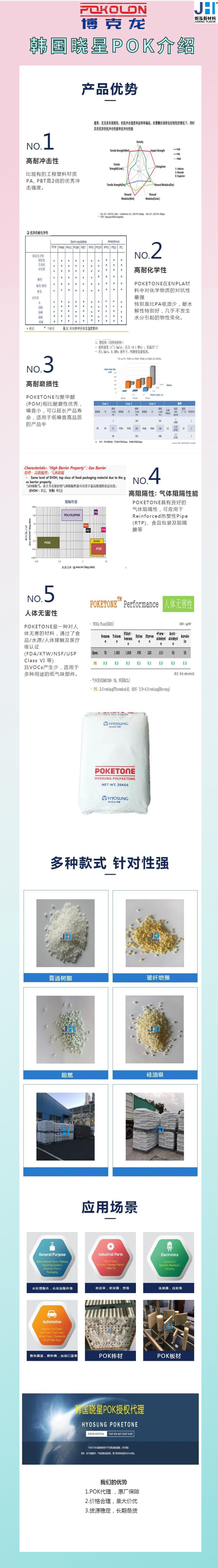

the new thermoplastic resin HYOSUNG POKETONE is a semi-crystalline polymer made from carbon monoxide and olefins.

POLYKETONE, a thermoplastic resin synthesized from carbon monoxide, ethylene and propylene, is widely used as an engineering plastic. At the same time, the application of copolymers of carbon monoxide and ethylene in the field of fibers and high-performance membranes is also under research and development.

HYOSUNG POKETONE is composed of unique characteristics, including excellent wear resistance and chemical resistance, excellent impact strength, barrier performance to gas and hydrocarbon, and hydrolysis resistance, which not only contributes to the sustainable development of society but also brings innovation to various industries such as automotive electronic and electrical packaging.

POK thermoplastic resin is a polyketone, a revolutionary semi-crystalline thermoplastic. It has good processing performance, good wear resistance, good chemical resistance, excellent hydrolysis resistance, good barrier performance, high resilience and good creep performance.

POK is a kind of engineering plastics with excellent comprehensive performance developed and produced by South Korea Xiaoxing group. It belongs to polyketone material and is a new green polymer material made by the polymerization of CO, ethylene and propylene.

After testing its high impact strength, compared to nylon, PBT impact strength is 230% higher, outstanding hydrolysis resistance. Usually PA66 has a very high tensile strength.

p But the impact strength and elongation are very low, POK also has excellent impact strength and elongation at sufficient tensile strength. POK has extremely high toughness and good enough tensile strength and flexural modulus.

The abrasion resistance is 14 times that of POM, the abrasion resistance is extremely low, the dimensional stability is high for long-term use, and the influence of temperature change is very small, and the low noise effect is outstanding. It has excellent hydrolysis resistance. Compared with nylon, polyester, etc. in cold water or hot water, its mechanical properties change is much smaller, basically equivalent to PPO and PPS, and can be used for a long time in water environment. POK has excellent hydrocarbon barrier properties, as well as good chemical resistance, due to its tight crystal structure, it has excellent barrier effect on various substances, is not lipophilic, non-hydrophilic, resistant to various chemical solvents 15 copies is equivalent to EVOH, and can form various barrier products through different processes such as extrusion, injection molding, blow molding, etc. The modified thermal deformation temperature is 200-215 ℃, its performance is better than many engineering plastics in high temperature environment, and its application field is wider; at low temperatures, due to the excellent low temperature toughness of the material, it is still good at minus 20-40 degrees C.

At the same time, POK also has excellent flame retardant effect-when POK Burns, hydrogen atoms and ketone groups react to generate water, and the carbon layer covers the surface to isolate it from oxygen and heat. The flame retardant additive was 50% of the nylon. (Flame retardant UL-VO grade)

POK has high production efficiency-high crystallinity POK helps to shorten the molding cycle and reduce production costs.

Compared with various common engineering materials, POK M330A has stronger performance than POM, 100P-POM plus Teflon series POK,M330F is food grade, and its performance is stronger than PA66 food grade series. POK plus glass fiber series completely replaces PPA series in the field of water purification. The unit price comparability is very high.

POK thermoplastic resins are not only excellent in the above-mentioned properties, but also have significant advantages in terms of environmental protection. Because of its relatively low carbon emissions in the production process, it is in line with the current concept of sustainable development. In terms of electrical properties, POK has good insulation properties and low dielectric constant, suitable for the manufacture of various parts in the field of electronic and electrical.

In addition, POK also has excellent fatigue resistance. Under repeated stress, it can still maintain good performance stability and extend the service life of the product.

In terms of color stability, POK can maintain color consistency and stability under long-term use and different environmental conditions, and reduce the appearance impact caused by color changes.

From the perspective of processing technology, POK has less wear on the mold, which helps to extend the service life of the mold and reduce production costs.

Moreover, POK shows good compatibility and synergy in composite applications with other materials, further expanding its application range and performance advantages.

POK product advantages: in line with the EU food contact level norms

1. As a new type of green polymer material.

2. Compared with Nylon and PBT, the impact strength is 230.

3. Excellent hydrolysis resistance.

4. Has excellent chemical resistance (POK's chemical resistance is extremely excellent in plastics, even in acid/alkali solution, its resistance will not decrease)

5. It has excellent fuel resistance (after 3000 hours of testing, the change is minimal, the performance is better than PA12 twice, it is the trend material of automobile tube)

6. With high thermal deformation temperature (POK Thermal Deformation temperature of 210 ℃, better than other materials, can be used in high temperature environment)

7. Show excellent friction properties (wear resistance is 14 times that of POM, is the current excellent material, almost long-term use without change)

8. With high barrier properties: gas barrier (equivalent to EVOH, due to good gas barrier properties, can be used for high-level food packaging; EVOH: multi-layer, polyketone: single layer)

9. High barrier to hydrocarbons (polyketone has excellent hydrocarbon barrier properties and good chemical resistance)

10. It has excellent flame retardant effect (when polyketone is burned, hydrogen atoms and ketone groups react to generate water, carbon layer covers the surface to isolate it from oxygen and heat, and the amount of flame retardant is 50% of nylon)

11. Excellent high elasticity and strain capacity/resilience and recoverability, higher than other engineering plastics

12. Realize the balance of stiffness and toughness (POK has extremely high toughness and good enough tensile strength and bending modulus, POK is an engineering plastic with balanced performance)

13. Guarantee high production efficiency (high crystallinity of polyketone helps to shorten the molding cycle, improve production efficiency)

14. Food contact level (FDA certified) water application treatment (NSF certified)

name/Brand/Performance/Application

Hyosung Polyketone

POK M230A high fluidity resin material oil tank cap, wheel hub and other appearance parts

POK M330A medium viscosity, resin material gear, bearing wear resistant element

POK M340A high temperature resistant resin material gear, bearing wear resistant element

POK M620A high viscosity, extrusion grade resin material extrusion grade tubing and joints

POK M630A high impact performance resin material cold resistant Grade wear resistant material

POK M640A low temperature high impact performance resin material cold resistant Grade wear resistant material

POK M730A *** viscosity, extrusion grade resin material extrusion grade tubing and joints

POK M330F food grade, grade, medium viscosity makeup industry, industry, tableware cups

POK M610F food grade, grade, easy to process makeup industry, industry, tableware cups

POK M630F food grade, grade, high viscosity makeup industry, industry, tableware cups

POK M730F food grade, grade, * * * sticky makeup industry, industry, tableware Cup h

POK M930F food grade, grade, high flow makeup industry, industry, tableware cups

POK M33AG7A medium viscosity, 35% glass fiber reinforced water meter water pump functional structure

POK M33FG7A 35% glass fiber reinforced, with KTW,W270 certification

POK M33AG3A medium viscosity, 15% glass fiber reinforced water meter water pump functional structure

POK M33FG3A 15% glass fiber, with KTW,W270 certification

POK M33AG4A medium viscosity, 20% glass fiber reinforced water meter water pump functional structure

POK M33FG4A 20% glass fiber reinforced, with KTW,W270 certification

POK M33AG6A medium viscosity, 30% glass fiber reinforced water meter water pump and other functional structural parts

POK M33FG6A 30% glass fiber reinforced, with KTW,W270 certification

POK M33AG9A medium viscosity, 50% glass fiber reinforced gear, water meter, oil pipe joint

POK M33FG9A 50% glass fiber reinforced, with KTW,W270 certification

POK M330AN6DA high impact ultra-tough modified sports equipment, auto parts, etc.

POK K950G35F-GN halogen-free phosphorus-free flame retardant, 35% glass fiber reinforced halogen-free connectors, electronic components

POK K950G35F halogen flame retardant, 35% glass fiber reinforced connector, electronic components

POK M33AS1A/M33AS1B medium flow, add silicone oil wear parts, gear parts

POK M63AS1A/M63AS1B low flow, add silicone oil wear parts, gear parts

POK M33AT2E medium flow, add silicone oil plus PTFE wear parts

POK M33AT2S medium flow, add silicone oil and PTFE wear parts

POK M330AF2JY in flow, flame retardant V0 appliances, auto parts

injection molding process:

baking material temperature: 80 ℃

drying Time: 2-4 H

injection temperature: 220-240 ℃

mold temperature: 60-80 ℃

note: The retention time of the barrel should not exceed half an hour. Use Ju Hong professional washing machine material JH810GW to clean.

POK plastic characteristics: balance of rigidity and toughness: It has high toughness and sufficient tensile strength and bending modulus, and its performance is balanced. High impact strength: Compared with Nylon,PBT has a high impact strength of 230. And outstanding hydrolysis resistance. In wet conditions to maintain high tensile strength and impact strength, and high elongation. High heat distortion temperature: HDT is 200 ℃, which can be used for a long time in high temperature environment. Outstanding chemical resistance: superior chemical resistance second only to PPS. Resistance to water and moisture stability High barrier properties: Hydrocarbons. Passed the permeability test of gasoline @ 93 ℃ * 15 days, which is better than Teflon, the gas barrier is equivalent to EVOH, superior friction performance: wear resistance is 14 times that of POM, and it has good low noise and high energy production efficiency: Polyketone with high crystallinity helps shorten the molding cycle.

POK plastic application: industrial and daily necessities: water, cosmetic bags, refrigerator doors, gears, seat accessories, overhead light locks, industrial cutting, brackets, hydraulic tightness, and other supplies. Applications of automobile fuel systems and under-hood covers: Engine cover, antifreeze tank, fuel tank, fuel pipe, fuel filler neck, ECU housing, LED radiator, cylinder head cover, radiator end groove. Application of automobile external components: door stop, fuel filler, tire chain, hub. Barrier tubes and packaging: barrier tubes, Tube caps, barrier packaging bottles, personal care products, food packaging. Electrical components: Connectors and plugs, disconnect switches, cable boxes. Transmission device: ATM/office automation gear, power steering buffer device

procurement Instructions

the price of the product is uploaded uniformly in the background, because the price cannot be changed one by one model, so please refer to ITU!

1. Can provide raw material factory and physical property table, UL yellow card, ROHS report, SGS and other information, quality assurance;

2. In our purchase of materials can provide technical support within the scope of our ability to provide relevant environmental protection and other information.

3. The company's raw materials can be ordered at a minimum of 25kg, with discounts or cash on delivery. When the company arrives in the Pearl River Delta, the goods will arrive in 3-4 days in all parts of the country. (All goods transported by logistics have outer protective bags, which can be opened during inspection). The materials purchased by our company can provide technical support within the scope of our ability and provide relevant environmental protection information.

4. Welcome to inquire about the nature of materials, provide physical property tables and provide processing related data.

5. The company sells raw materials are the original original packaging genuine materials, signed the purchase and sale contract and quality assurance, long-term cooperation!