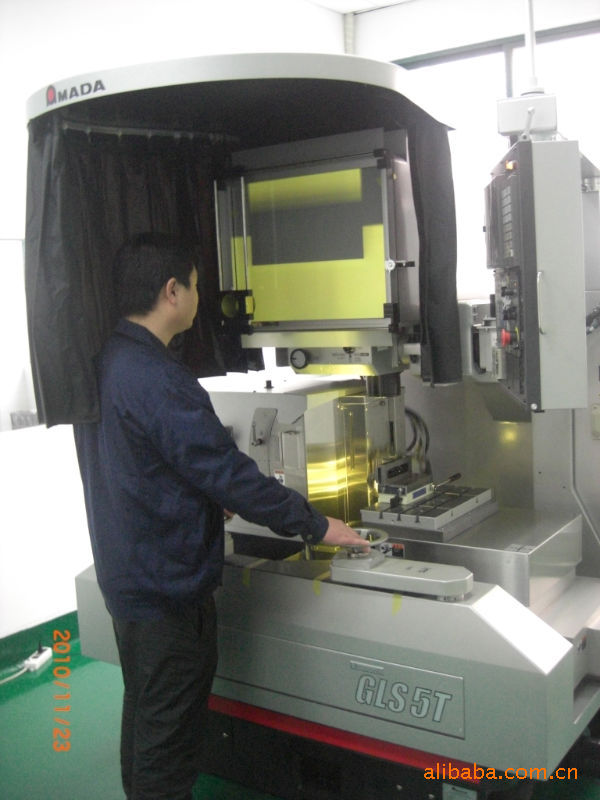

昆山西诺巴精密模具有限公司主要以光学研磨加工和慢走丝加工为主,光學投影研磨機又名pg.原產自日本waxinuo公司,型號為waxinuo5T.其主軸最高轉速可達到30000轉.上下行程最大為110mm.

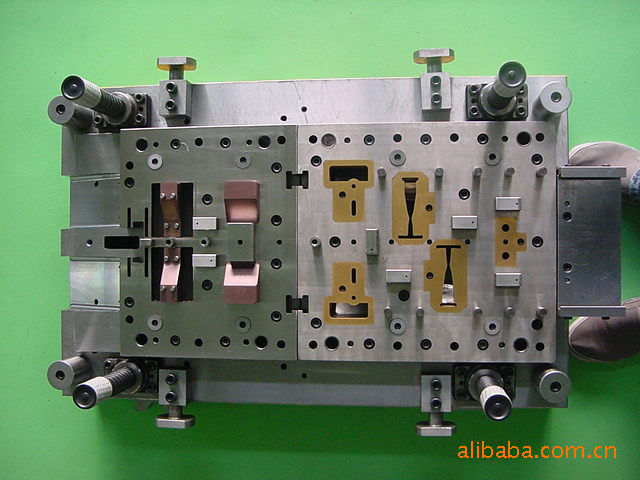

上下行程速度最高為400次/mm.其主要材料加工為較精密的半行程衝子,下模入塊和脫料板入子,加工的主要材質為較硬的碳化鋼,偶爾也加工一些普通鋼材,

如SKH-9、

ASP60、SKD11料等,PG加工的精度在+/- 0.002以內,其機臺的最小尺寸單邊為0.0001mm,加工的最小內R角為R0.03.外R角為R0.02,

加工異形衝子最薄處可達到0.06mm.其加工的溝槽為寬度/深度=1/2左右,加工過程中.根据工件大小而進行放大20倍或50倍進行加工。

我公司主营产品和服务:LED冲头加工,光学曲线磨床加工,精密五金塑胶模具配件模具标准与非标准件批量提供五金高速冲压模具研发以及相关连接器类接插件产品wafer housing terminal现货代理模具加工用进口成型砂轮金刚石砂轮指定代理日本进口钨钢RD20 RD50 RD30 RD60等各种规格板块。

从事(Profile Grinding)光学研磨加工,超硬材质成型研磨,精度稳定达到0.001mm。我司的主Wasino GLS-5T CNC光学投影研磨机JAPAN原产,检测设备:NIKON 50X投影机1SETMitutoyo 0-50高度计1SETSwiss GR千分表1SETMitutoyo分厘卡7SET0级大理石平台1SET爱纳德模具有限公司凭着品质第一,交期准时,客户至上的理念在模具加工行业中脱颖而出,逐渐成为众多知名企业的认可与信赖。在当今高科技,高精度的环境中,愿意与我们的客户一起组成战略合作伙伴,一同迎接新技术的挑战。硬质合金模具/工具/刀具最新加工方式 ----PG光学研磨,曲线研磨加工介绍适合参数:高硬度工件:工件硬度(HRA) ~~88—96 表面粗糙度:RZ~~0.2um / F1.0mm/min 工件热变位:<=2um 四轴四联动:X.Y~~0.0001mm / U.W~~0.0005mm 加工方式:光学投影加工适合工件:钨钢件—要求具有高度之韧性/压缩强度及硬度件。适合行业: IT产业的超薄连接器冲模用刀口及冲头,高速精密冲床用模具等。顺祝!商祺