ER-008638

Probe with ball ø5 mm

ER-010562

Probe with ball ø2 mm

For safety, guarantee, liability

and service addresses, see

Appendix A.

Note:The probe is a very

accurate measuring instrument

and must be treated with the

appropriate cleanness. If the

probe shows any signs of

improper handling, hits or any

subsequent machining, this

shall preclude any claims to

indemnification under

guarantee.

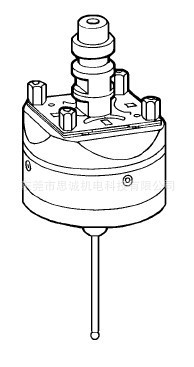

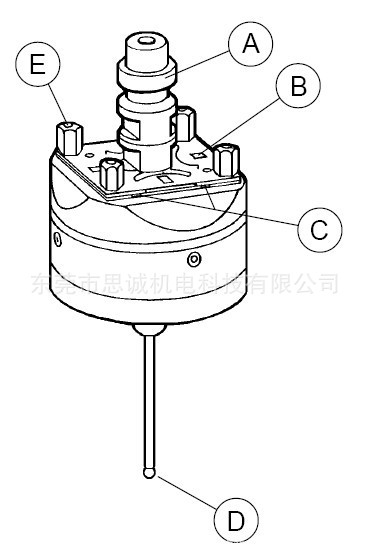

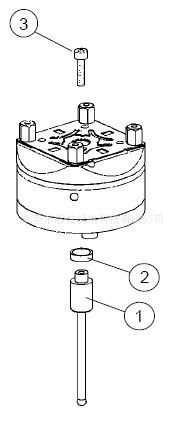

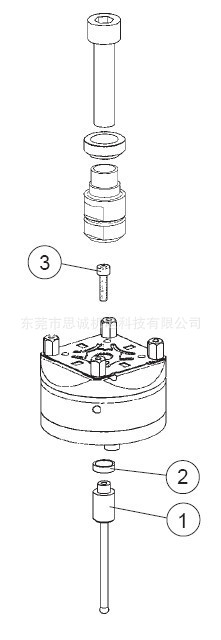

Description of parts

A) Chucking spigot

B) Centering plate

C) Reference mark

D) Probe pin with

ball ø 5 mm or ø 2 mm

E) Supporting feet

Note: Neither loosen nor

retighten the support feet.

Application

Automatic aligning

of workpieces on CNC

EDM machines.

Technical data

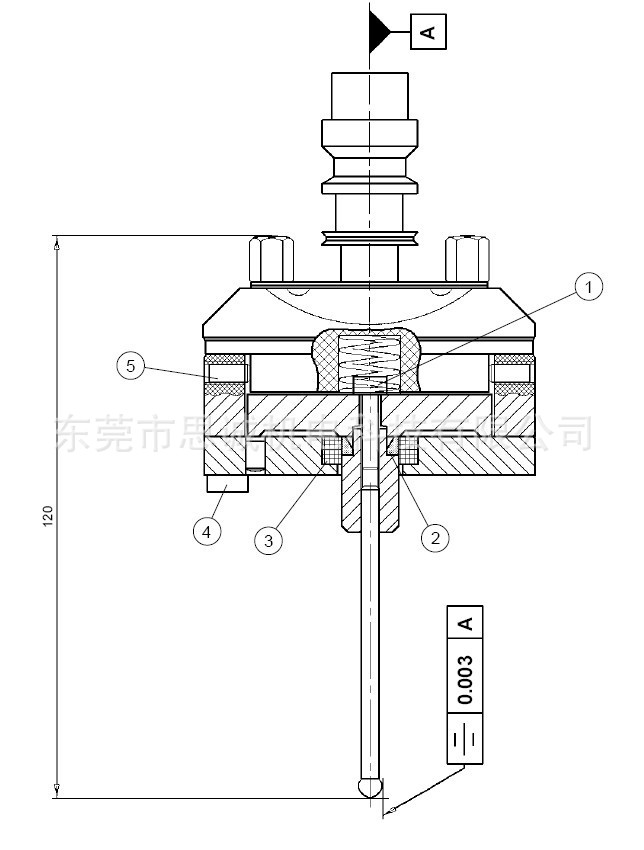

1) Bolt M4 x 16

2) Adjustment washer

3) Sealing ring

4) Bolts M5 x 30

5) Threaded pins

Setting up

Setting up

Clamp the probe into an ITS

chuck in relation to the

reference side. Start the

measuring /aligning program

of the CNC machine.

The rotation axis may be run

at low revolutions. The probe

works on the principle of

electric contact. However, it

has an overshoot protection of

1 mm in the X- and Y-axes and

of 0.5 mm in the Z-axis. Carry

out the desired measurement.

When doing so, take into

account the ball diameter.

Note:The concentricity of the

probe should be checked from

time to time, and corrected if

necessary.

This is done most easily on

an ITS measuring station or

an equivalent facility with a

flat-contact probe (no ball).

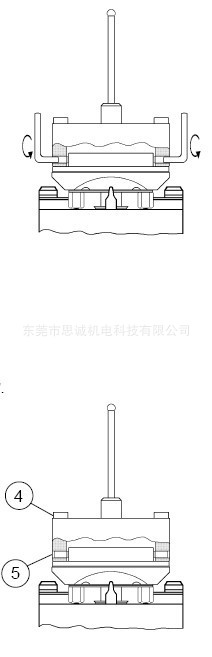

Lightly loosen the three bolts

(4) so that the U-washers

remain in place.

Correct concentricity with the

four threaded pins (5). To do

so quickly and accurately, the

following points must be

observed:

Point 1:

Correcting in the 0°-180° axis.

Set the dial gauge to zero at 0°

or 180°. Turn probe round 180°

to make the deviation visible on

the dial gauge so that it can be

corrected. When correcting

concentricity, halve this value

and move the probe into the

centre with the threaded pins.

Always use two opposite pins

for the purpose.

How to proceed:

Loosen one pin, tighten the

opposite pin. After the

correction has been completed,

give the two threaded pins a

slight turn in the same direction

and proceed to the next step.

Point 2:

Correcting in the 90°-270° axis.

Turn the probe round 90° and

set the dial gauge to zero at

90° or 270°. Determine the

deviation, then correct

concentricity as in Point 1.

Point 3:

When you have achieved the

desired precision (0.003 mm),

lightly tighten bolts (4). Check

concentricity again and correct

if necessary. To this purpose,

the whole "How to correct

concentricity" process must be

repeated.

Finally, gradually tighten bolts

(4) until you reach a torque of

5 Nm. Give the threaded pins a

slight turn in the same direction.

Check concentricity.

Replace probe pin

If the probe pin should break,

it can be replaced in a simple

manner:

- Remove chucking spigot

- Loosen bolt (3) through

the M10 thread with a hex

key.

- Pull out probe pin (1).

Caution: Do not lose the

spacer (2).

- Insert replacement probe

pin into spacer (2) and

fasten with bolt (3) to a

torque of 3.5 Nm.

- Attach chucking spigot.

- Set concentricity (see

"How to correct concentricity").

Malfunctions,

trouble-shooting

E=Error, C=Cause,

R=Remedy

E : Probe is not concentric.

C : a) Chucking spigot mounted

in the wrong way.

b) Probe damaged.

R : a) Mount chucking spigot

according to the manual.

b) -Replace probe pin.

-Check concentricity.

-Return probe to your

EROWA representative

for repair.

Spare parts

ER-010560

Replacement probe pin ø 5 mm

ER-010561

Replacement probe pin ø 2 mm

思诚机电科技有限公司主要销售以下产品:

瑞士EROWA 柔性加工定位夹具

德国BLUM产品系列,CNC用激光对刀仪、接触式对刀器、在线测量探头

美国VEKTEK液压夹具系列

电加工耗材系列(韩国纸芯过滤器、铜线等)

以色列NOGA万向磁性表座、刮刀,手动去毛刺系列

瑞士GIROD-TAST红宝石杠杆表

台湾Toltel影像影像显微量测仪(TTC放大镜)