如何正确选择合适的拉拔器?

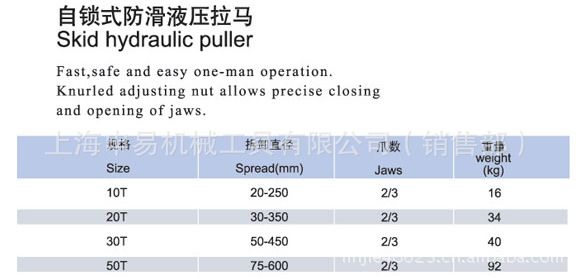

1、 丈量被拆物外径及厚度和所需要拉拔长度。

2、 在空间允许时尽量选择使用3爪拉拔器,以获得更可靠的夹持力以及更均匀的拉力。

3、 使用正确尺寸的拉拔器!如果您用了最大出力而工件没有被拉动,请使用更大吨位数的拉拔器。

4、 一般所需拉力的计算,被拆物内径1英寸约需7-10吨的拉力。

5、 始终用防护安全网盖住工件,工件被拉拔时会产生很大的作用力在上面,有时会导致破裂(如多数皮带轮等材质是生铁为主),可减低操作人员受飞出工件伤害的危险。

6、 逐渐的施加拉力,不要允试在拉拔器加压杆或用动力扳手或延长加力杆来加速拉拔。

7、 尽可能用标准爪,较长拉爪会使拉拔器末端出力减少。

CONSIDERATIONS:

Determine the type of puller which puller type is best suited for gripping the parts?

Is a combination of puller types required? Or others?

Determine the reach needed for your particular pulling problem.

The puller you select must have a reach equal or greater than the corresponding sizes of parts to be pulled.

Determine the spread need. The spread is determined by the width of the parts being pulled. The pulled. The pulled spread should be greater than the width of the part to be pulled.

Estimate the force needed to solve your pulling problem.

Remember 1″draft need 10tonnes force!A puller with the proper reach and spread will usually have enough capacity to remove the corresponding part. When in doubt ,always use a puller with a large area of resistance may need more pulling force.

DO NOT EXCEED EQUIPMENT RATINGS

SELECT 3JAWS NOT 2 JAWS TO GET FIRM GRIP FORCE!

SELECT STANDARD ARMS(JAW) NOT EXTRA LONGG ARMS!

PLEASE COVER SAFETY NET WHEN WORKING TO AVOID INJURY!

AVOID DAMAGING HYDRAULIC HOSE!