FTTH-G657A-256光纤束抽取式光缆

深圳市宽通光缆科技有限公司

中国 深圳

产品属性

图文详情

品牌推荐

品牌/型号

KONTOON/FTTH-G657A-256光纤束抽取式光缆

光纤芯数

256

光缆外径

10.5(mm)mm

重量

50(kg/km)kg/km

允许抗拉强度

200(N)N

允许侧压力

200(N/100mm)N/100mm

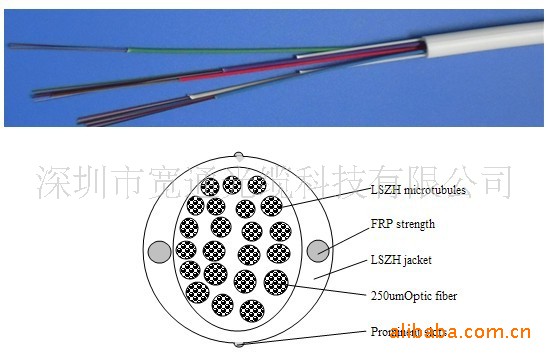

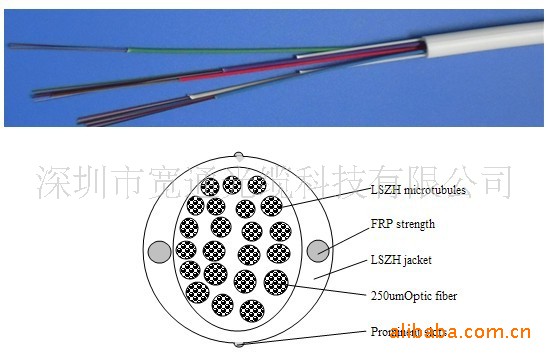

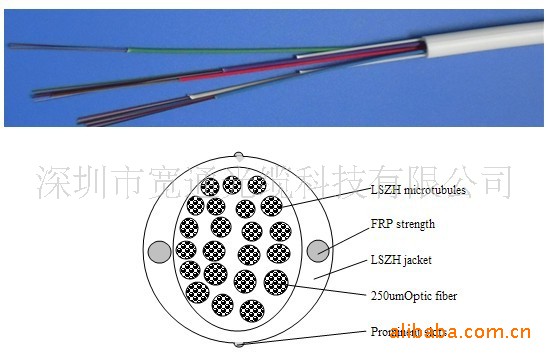

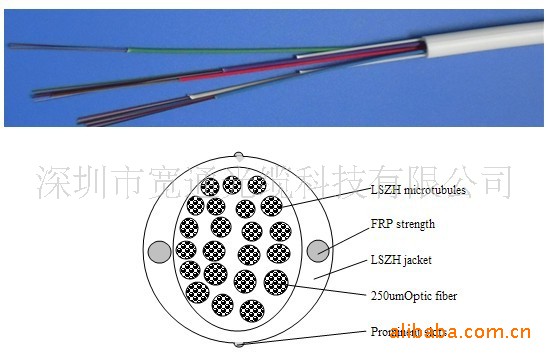

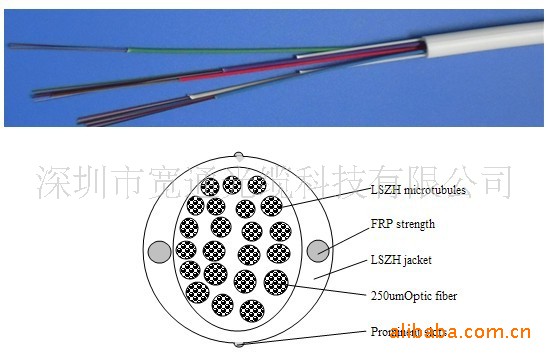

| Description | |||||||||||||||

| Tight buffered fiber without jelly compound | |||||||||||||||

| Both sides FRP strength members | |||||||||||||||

| LSZH outer sheath available | |||||||||||||||

| Round construction for minmum wind drag | |||||||||||||||

| LSZH microtubules | and ice buildup increases span length capability | ||||||||||||||

| Prominent slots opening side location | |||||||||||||||

| FRP strength | The termination can be made standard connector | ||||||||||||||

| LSZH jacket | Application | ||||||||||||||

| Suitable for aerial,pipeline,bracket laying, | |||||||||||||||

| 250umOptic fiber | Suitable for indoor and outdoor cable | ||||||||||||||

| FRP strength members reduce weight | |||||||||||||||

| Prominent slots | for longer span lengths | ||||||||||||||

| Lightweight,all dielectric self-supporting(ADSS) | |||||||||||||||

| construction is ideal for use near electrical power lines | |||||||||||||||

| Quality Assurance System | |||||||||||||||

| Optical testing follows ITU, IEC and EIA/TIA-FOTP | |||||||||||||||

| Quality approved by UL | |||||||||||||||

| Mechanical & Environmental characteristics | |||||||||||||||

| ITEM | CHARACTERISTICS | ||||||||||||||

| Operation temperature | -20℃~+60℃ | ||||||||||||||

| Jacket Material | LSZH | ||||||||||||||

| Part Number | Fiber Count | Outside Diameter (mm) | T.B Diameter (mm) | Cable Weight (kg/km) | Tensile Load | Crush Load | Bend Radius | ||||||||

| S (N) | L (N) | S (N) | L (N) | S (mm) | L (mm) | ||||||||||

| KT04DIFXXL-WF | 256 | 18.5 | 1.4 | 235.0 | 500 | 200 | 400 | 200 | 20D | 10D | |||||

| Note: KT denotes company logo; XX denotes fiber P/N code(52D: G.652D; 57A: G.657A;50: 50/125um;09: G.652) ; | |||||||||||||||

| 04 denotes fiber count 4 fibers ; L denotes LSZH | DIF denotes distribution tight buffer FRP strength optic cable | ||||||||||||||

| WH denotes the white outer sheath; | |||||||||||||||

| Tight Buffer colour Code | |||||||||||||||

| 1~12 fibers: Blue, Orange, Green, Brown, Grey, White, Red, Black, Yellow, Purple, Pink, Aqua | |||||||||||||||

| 13~24 fibers: Blue, Orange, Green, Brown, Grey, White, Red, Black, Yellow, Purple, Pink, Aqua | |||||||||||||||

| -----with short black stripes | |||||||||||||||

| 25~36 fibers: Blue, Orange, Green, Brown, Grey, White, Red, Black, Yellow, Purple, Pink, Aqua | |||||||||||||||

| -----with short red stripes | |||||||||||||||

| 37~48 fibers: Blue, Orange, Green, Brown, Grey, White, Red, Black, Yellow, Purple, Pink, Aqua | |||||||||||||||

| -----with short green stripes | |||||||||||||||

| Note: | |||||||||||||||

| 1 | The colour identification of the buffer layer complies with the standard colour identification set in | ||||||||||||||

| GB13993.3-2001 Standard | |||||||||||||||

| 2 | S: short term; L: long term; T.B: tight buffer | ||||||||||||||

| 3 | Crush load: N/100mm; D: cable diameter | ||||||||||||||