ECON-08全自动高效型锡渣分离机简介

一. 产品特点及参数Product features and parameters:

A、电控系统 Electronic System: |

1、人机界面:WEINTEK TAI WAN触摸屏5.7″;

HITECH GUI interface:WEINTEK TAI WAN 5.7" touch creen |

2、时间制工作:可提前预制时间设置,自动开关机;

Timer operation: time pre-setting, automatic turn on/off |

3、数显式电流表,直接监控各区发热管工作状态,

Digital current meter controls heating tube working status of all zone. |

4、加热方式,模拟量PID功能,无触点可控硅控制;

PID function heating mold with zero touch |

B、锡渣输入系统:Dross loading system |

采用同步螺旋自动将碎锡渣输入进搅拌区焊锡内部,锡渣周转盒,一次可装20KG容量;

In-phase screw scraps dross and drive it into mixing aera which equped with dross powder container of 20kg capacity. |

C、搅拌系统:Mixing System |

1、搅拌区底锡容量:90KG,外加热式融锡系统:使锡渣加热均匀,升温快,节约电能;

90kg capacity with outside heating mold melting system. It maks tin warm up evenly and rapidly, save energy. |

2、搅拌电机400W 380V 3P 采用蜗轮蜗杆传动搅拌机构,更省力,同时避免电机与高温部件直接接触

400W 380V 3P mixing motor uses worm wheel structure to avoid motor directly connect with high temperature part. |

3.特殊设计的搅拌机构,使锡渣均匀融解并实现一级粗分离;

Special designed mixing structure makes dross evenly melted. |

4.测温热电偶,检测液态焊锡的温度,更精确的反馈锡渣的融解温度;

Temperature couple check liquid dross temperature and feedback acurately. |

D、分离系统:Separation System |

1、分离区底锡容量:30KG,外加热式融锡系统,使焊锡受热均匀,升温快,节约电能;

30kg pure tin at the bottom of separation part with outside melting system makes dross evenly warm up. |

2、分离筒、螺旋采用进口耐高温耐腐蚀的特殊不锈钢316L材料制做加工;

Separating tube and screw use 316L material |

3.分离方式:采用双螺旋结构,形成双通道,更利于渣液分离,不易堵塞;

Separation: Uses double screw structure easly separate dross and pure tin without block up. |

4.锡灰收集箱自动报警功能,根椐箱内收集锡灰的重量自动检测,达到定量时自动报警,提示清理;

Automatic warning function in dross powder container. |

E、出锡成形系统:Pure Tin Molding System |

1、分离出来的焊锡收集区:容量达30KG,采用排体方式自动定量排锡,确保锡条成形均匀性

When pure tin reaches to 30kg, the machine automaticly discharge the tin out to the container. |

2、标准成形铝槽:1.3KG/槽,17槽;

Molding slot: 1.3kg/slot, 17pcs slots |

3、自动输出装置:与排锡电机同步动作的输出,完全确保高温焊锡的收集与输送;

Automatic output device: in-phase with discharge sysyem to collect and output the pure tin. |

4.内置强制冷却:成型锡条极速冷却,减少氧化,加快成型,提高效率;

Inner force cooling system makes tin bar cool down in short time. |

F、烟雾净化系统;Fog purify system |

1、一级过滤箱体:利用循环式水冷管致冷,使高温气化松香快速冷却,以形成液态下落进行收集;

First Filter Box uses recycle water cooling to make gas rosin cool down to becomes liquid material to be easly collected. |

2、二级过滤箱体:采用水帘式过滤+阻燃过滤棉+活性碳棉三重方式,可完全过滤烟雾中的颗粒与异味气体

Second filter box uses watwr shade + anti-burnt filter foam + activated carbon foam |

3、排风电机:750W 380V 3P

Exausting fan: 750W 380V 3P |

G、整机基本参数;Body Parameters |

1、外观采用流线型圆弧加立体三维设计,绿色圆弧玻璃,美观大方,带有视窗,方便维护和操作。

Streamline appearance with 3D design, green arc glass to see the operation and easy maintenance. |

2、整机电源 Power Supply:3P 4¢ 380V /AC |

3、整机尺寸Size:L1600mm*W1200mm*H1500mm;

重量 Weight 800KG |

4、整机功率Power:7KW

工作功率 Working Power 2.3KW |

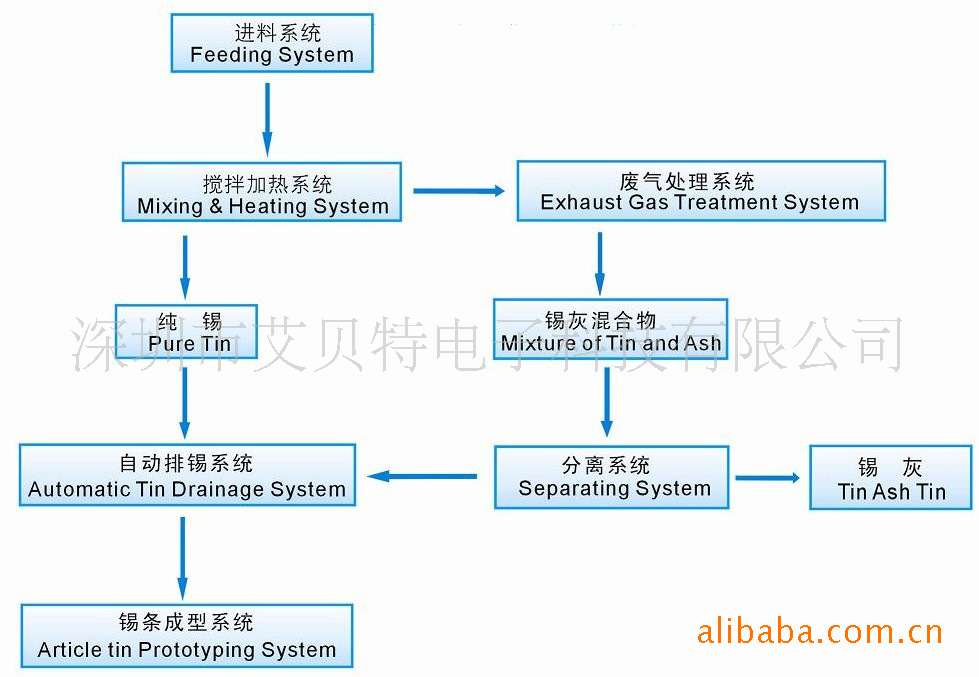

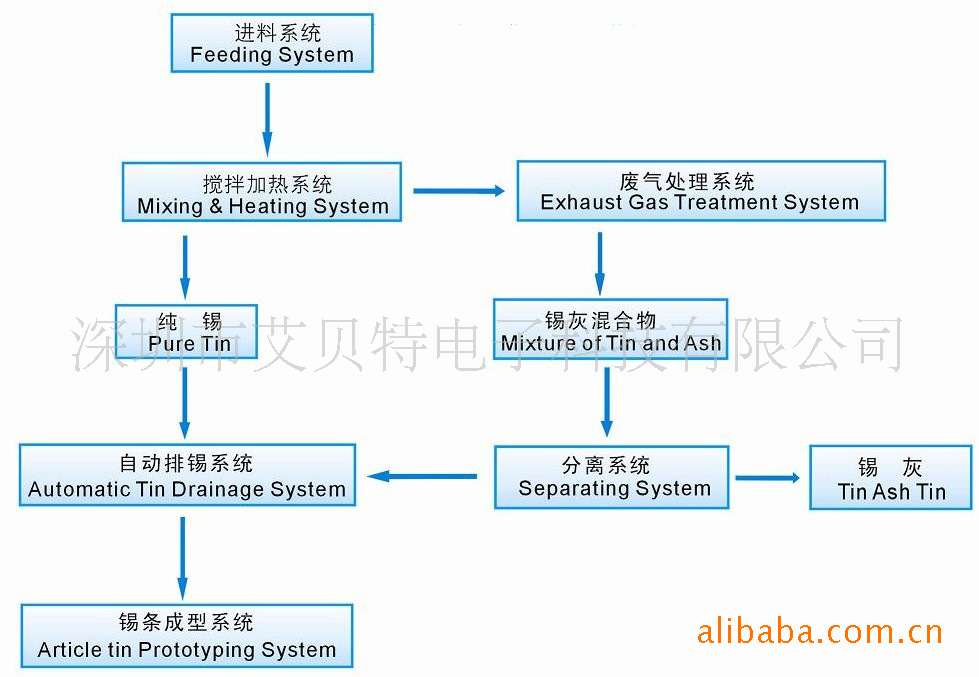

二. 工作流程Operating Process

一. 技术参数Technical parameters