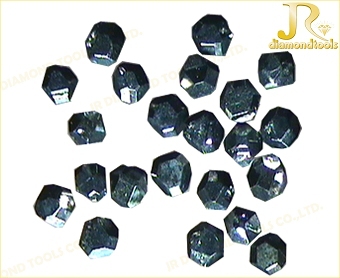

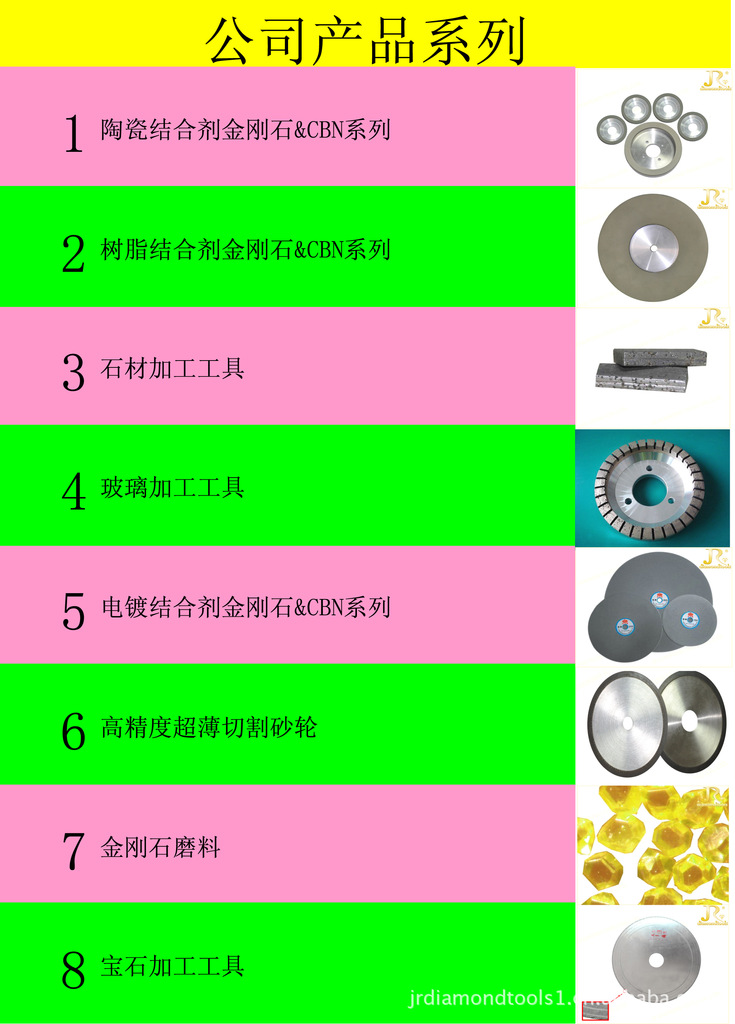

型号 Item NO. | 涂层 Coating | 图片 Picture | 应用 Application |

DJN1 |

镀镍 Ni coated |  | 适用于树脂结合剂工艺或陶瓷结合剂工艺。 它表面的尖突结构使金刚石能更好地与结合剂粘合并获得优良的热传导性。常用于各种金刚石 砂轮,尤其是金刚石软磨片。湿磨具有更好的效果。Suitable for resin bond system or vitrified bond system. Its surface structure with spiky protrusion gives diamond the superior attachment to the bond matrix and excellent heat conductibility. Used for diamond grinding wheel and so on, especially for diamond flexible polishing pad.

|

DJN2 | 镀铜 Cu coated |  | 适用于黑色金属,硬质金属或树脂结合剂砂轮。能增强金刚石的附着力,从而延长砂轮的使用寿命,并提高对产品表面抛光的效果. 湿磨具有更好的效果。 Adequate for ferrous metal, hard metal or resin bond grinding wheel. Able to enhance the mechanical attachment of diamond ,and thereby expand the life of wheel and improve the effects of surface finish. Wet milling has better effects.

|

DJN | 镀铬 Cr coated |  | 适用于树脂或青铜结合剂砂轮。能增强金刚石的附着力,从而延长砂轮的使用寿命,并提高对产品表面抛光的效果.干磨具有更好的效果。 Suitable for resin or bronze bond grinding wheel series. Able to enhance the mechanical attachment of diamond ,and thereby expand the life of wheel and improve the effects of surface finish. Dry milling has better effects.

|

DJT | 镀钛 Ti coated |  | 适用于金属结合剂产品。能增强金刚石的附着力,并借助钛与金属间的治金结合作用来保护金刚石不被石墨化,从而保证了金刚石的强度和其它特有属性得到充分的利用。 Used for metal bond products. Able to improve the attachment of diamond and protect diamond from graphitization by metallurgical bonding between Ti and metal, and thus ensure the intensity and application features of diamond.

|

可根据客户所需定做

| 国内外金刚石粒度及尺寸对照表(Diamond grit size specification) | ||||||||||||||

| 单位:微米(Unit:μm) | ||||||||||||||

| 中国GB/T6406-1996 | 国际标准ISO6106-1979 | 西欧共同体FEPA-1977 | 美国ANSI B74.16-1971 | 日本JIS4130-1982 | 西德DIN848-1988 | 俄罗斯TOCT9202-80 | ||||||||

| 粒度号 | 尺寸范围 | 粒度号Ⅰ | 粒度号Ⅱ | 尺寸范围 | 粒度号 | 尺寸范围 | 粒度号 | 尺寸范围 | 粒度号 | 尺寸范围 | 粒度号 | 尺寸范围 | 粒度号 | 尺寸范围 |

| Grain | Size | GrainⅠ | GrainⅡ | Size | Grain | Size | Grain | Size | Grain | Size | Grain | Size | Grain | Size |

| 16/18 | 1180~1000 | 1181 | 16/18 | 1180~1000 | D1180 | 1180~1000 | 16/18 | 1180~1000 | 16/18 | 1180~1000 | D1180 | 1180~1000 | 2500/2000 | 2500/2000 |

| 18/20 | 1000~850 | 1001 | 18/20 | 1000~850 | D1001 | 1000~850 | 18/20 | 1000~850 | 18/20 | 1000~850 | D1001 | 1000~850 | 2000/1600 | 2000/1600 |

| 20/25 | 850~710 | 851 | — | 850~710 | D851 | 850~710 | 20/30 | 850~600 | 20/30 | 850~710 | D851 | 850~710 | 1600/1250 | 1600/1250 |

| 25/30 | 710~600 | 711 | — | 710~600 | D711 | 710~600 | 710~600 | D711 | 710~600 | 1250/1000 | 1250/1000 | |||

| 30/35 | 600~500 | 601 | — | 600~500 | D601 | 600~500 | 30/40 | 600~425 | 30/40 | 600~500 | D601 | 600~500 | 1000/800 | 1000/800 |

| 35/40 | 500~425 | 501 | — | 500~425 | D501 | 500~425 | 500~425 | D501 | 500~425 | 800/630 | 800/630 | |||

| 40/45 | 425~355 | 426 | — | 425~355 | D426 | 425~355 | 40/50 | 425~300 | 40/50 | 425~355 | D426 | 425~355 | 630/500 | 630/500 |

| 45/50 | 355~300 | 356 | — | 355~300 | D356 | 355~300 | 355~300 | D356 | 355~300 | 500/400 | 500/400 | |||

| 50/60 | 300~250 | 301 | 50/60 | 300~250 | D301 | 300~250 | 50/60 | 300~250 | 50/60 | 300~250 | D301 | 300~250 | 400/315 | 400/315 |

| 60/70 | 250~212 | 251 | — | 250~212 | D251 | 250~212 | 60/80 | 250~180 | 60/80 | 250~212 | D251 | 250~212 | 315/250 | 315/250 |

| 70/80 | 212~180 | 213 | — | 212~180 | D213 | 212~180 | 212~180 | D213 | 212~180 | 250/200 | 250/200 | |||

| 80/100 | 180~150 | 181 | 80/100 | 180~150 | D181 | 180~150 | 80/100 | 180~150 | 80/100 | 180~150 | D181 | 180~150 | 200/160 | 200/160 |

| 100/120 | 150~125 | 151 | 100/120 | 150~125 | D151 | 150~125 | 100/120 | 150~125 | 100/120 | 150~125 | D151 | 150~125 | 160/125 | 160/125 |

| 120/140 | 125~106 | 126 | 120/140 | 125~106 | D126 | 125~106 | 120/140 | 125~106 | 120/140 | 125~106 | D126 | 125~106 | 125/100 | 125/100 |

| 140/170 | 106~90 | 107 | 140/170 | 106~90 | D107 | 106~90 | 140/170 | 106~90 | 140/170 | 106~90 | D107 | 106~90 | 100/80 | 100/80 |

| 170/200 | 90~75 | 91 | 170/200 | 90~75 | D91 | 90~75 | 170/200 | 90~75 | 170/200 | 90~75 | D91 | 90~75 | 80/63 | 80/63 |

| 200/230 | 75~63 | 76 | 200/230 | 75~63 | D76 | 75~63 | 200/230 | 75~63 | 200/230 | 75~63 | D76 | 75~63 | 63/50 | 63/50 |

| 230/270 | 63~53 | 64 | 230/270 | 63~53 | D64 | 63~53 | 230/270 | 63~53 | 230/270 | 63~53 | D64 | 63~53 | 50/40 | 50/40 |

| 270/325 | 53~45 | 54 | 270/325 | 53~45 | D54 | 53~45 | 270/325 | 53~45 | 270/325 | 53~45 | D54 | 53~45 | ||

| 325/400 | 45~38 | 46 | 325/400 | 45~38 | D46 | 45~38 | 325/400 | 45~38 | 325/400 | 45~38 | D46 | 45~38 | ||

| 注:1、英国标准BS5851-1980等同ISO6106-1971。 | Remark:1.UK standard BS5851-1980 is the same as ISO6106-1979. | |||||||||||||

| 2、尺寸按ISO565网孔尺寸。 | 2.Size above is in accordance with ISO565 mesh. | |||||||||||||