3.1 应用

(Appliance)

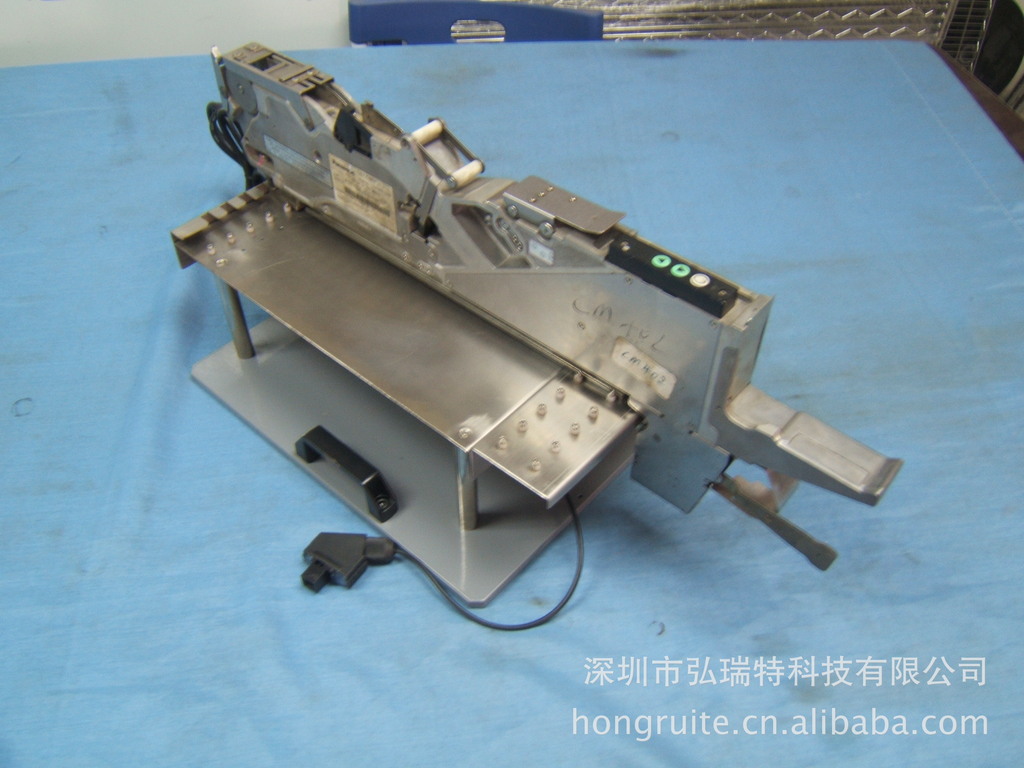

本产品采用夏普彩色CCD 和50高倍放大镜,通过MONITOR观察进料情形,顶针上下运动情况,LEVER磨损情况,减少料架不良所引起的抛料问题,对提高贴装良率有很好的帮助.

(This product adopts CCD with high times magnifier, through a MONITOR observation into components situation, Lever needle up and down work conditions, the LEVER fray, decrease FEEDER false and the cause of throwing problem, to the exaltation the good chip-placement ratio more help.)

3.2 特色

(Characteristically)

3.2.1 操作简单,外观简洁小巧.

(3.2.1 The operation is simple, the external appearance is simple and

cleverly.)

3.2.2 X,Y,H三轴采用日本进口高精度齿轮传动,精密可靠.

(3.2.2 X, Y, H -three stalks, adoption Japan importing and the high accuracy wheel gear drive, precision and credibility.)

3.2.3 50倍放大CCD;与LED照明使画面更清晰.

(3.2.3 50X CCD;with LED lighting, appearance clearer.)

3.2.4 配置电动方式,单动或者连续打击LEVER, 模拟机器动作.

(3.2.4 Install dynamoelectric, single and continuous strike LEVER, simulate machine action.)

3.2.5 观察齿轮动态走料的情况.

(3.2.5 Observing the wheel gear dynamic state step the conditions.)

3.2.6 配备标准校正尺以调整吸料中心.

(3.2.6 With standard calibration Ruler to adjust component centeral.)

3.3 规格

(Specification)

工作电压 (Working Voltage ) | 220V/AC(50Hz) 60W

|

机器尺寸 (Machine Size) | 350*500*550 mm |

机器重量 (Machine Weight) | 45Kg |

安装和使用

(Installation and Use)

1. 开机:将校正仪的信号线接入显示器的VIDEO接口,确认电源,将显示器和校正仪的电源接入.

(Switch on: use the Jig. correct signal wire connects into the display VIDEO plug, confirming power supply, correct connects into the power supply and monitor.)

2. 按下电源开关, 校正仪的压杆如不在原点位置,将会自动回到原点位置.此时显示器上将有十字光标显示,机器完成自检.

(Press power switch, the Jig. Press-pole has not original position, will return to original position automatically. The display will show cross cursor, The Jig. Completed self-check.)

3. 操作面板的使用:

(The usage of Operate front-panel :)

POWER (ON/OFF) 电源开关: 用来控制机器电源开关,

按到ON方向, 机器接入电源, 按OFF方向, 断开机器电源.

(a. POWER (ON/OFF) power switch: Use to control machine power switch,

Press ON direction, the machine connects into power supply, pressing OFF direction, breaking the machine power supply .)

FEEDER 调校

(Feeder Calibration)

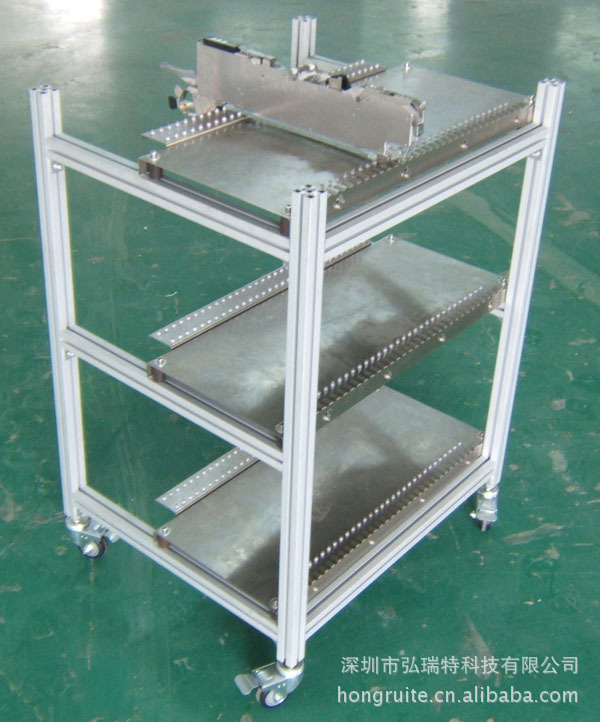

1. 将校正尺装到一支生产中贴装率最好的FEEDER上,将FEEDER装到放置平台.

(1. Install the Calibration Ruler to the best chip-placement ratio of FEEDER, place FEEDER to position table.)

2. 调整焦距H轴使显示器照到FEEDER的吸料位置中心,于显示器中十字光标的交叉点上清晰可见再锁紧,再调整X,Y轴使FEEDER的吸料位置小孔中心于显示器中十字光标中心交叉锁紧.到这里准备工作已经完成;请千万不要再调动X,Y,H轴.

(2. Adjusting the focus-distance H-stalk makes display position centeral on FEEDER component,display show cross cursors in the middle of intersection, clear again and lock tight, readjust X, Y -stalk makes display position centeral on FEEDER component -eyelet centeral in the middle of intersection, and lock tightly. preparative work to have already completed; never adjust X, Y, H- stalk again.)

3. 取下装有校正尺的FEEDER;将要校正的FEEDER装上校正尺放到校正仪FEEDER放置治具上,按下单动键观察吸料中心是否和显示器中的交叉处吻合,如不吻合请调节FEEDER上的偏心螺栓使之吻合.检查一下齿轮有没有磨损,和调节后的螺丝有没有锁紧.

(3. Take the FEEDER with Calibration Ruler, Place the calibration ruler into the adjustment FEEDER and setup to the Jig. position, press Auto/Manual key observe cross cursor centeral whether component cross place to superposition together, if not, please adjust FEEDER bolt-pin to make with display superposition together.Check once wheel gear, and lock screw tightly.)