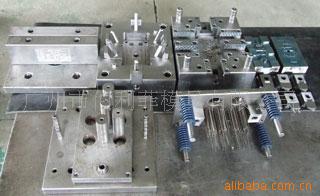

经营范围:注塑模具 、塑料模具、压铸模具、锌铝合金模具、注塑加工、喷油丝印。

1/模具流程:审图---备料---加工---模架加工---模芯加工---电极加工---模具零件加工---检验---装配—飞模---试模---生产

2/注塑加工流程:确定产量排单---备料---确认产品质量、结构、尺寸---生产---QC巡检---装箱。

模具加工设备:数控车床、慢走丝、电火花、线切割、钻床、磨床、普通铣床、高速CNC电脑锣。

注塑加工设备:精密注塑机、(80T—320T)16台、测试仪、破碎机5台、混色机3台。

加工能力:模具设计、模具制造及注塑成型加工

模具材料: P20,718,718H,2738,2316,S136,供您选择,模架:45#预硬>30 hrc

冷却系统:优化设计的循环流水,提高生产效率,降低您的成本

中期处理:调质,提高硬度。

后期处理:氮化(氮化处理温度低,变形很小,不再需要进行淬火便具有很高的表面硬度(大于HV850)及耐磨性)。

模具寿命: P20正常使用不低于30万模次。

运输方式:在模具出运前必须装上锁模片,物流运输。

售后服务:模具保修1年,保修期间免费维修。

本公司位于广州市番禺区沙湾镇福龙工业区,主要为客户承接精密的塑料模具及塑料产品开发、设计与制造,承接电火花。塑料产品加工如:各类电器塑料壳、灯饰壳、塑料日用品、塑料医用品、各种充电器、汽车用品、文具盒等,我们会热情为客户一条龙服务。

工厂拥有多年的生产经验、丰富的管理人员及质检人员,有浓厚的技术力量、专业的高级设计师。

张建成(业务代表)13113960423

QQ:893180301/邮箱:gzs16868@

Business: injection mold, plastic mold, die casting mold, zinc aluminum mold, injection molding, injection printing.

1 / mold process: trial plan --- in materials processing --- --- --- punch mold machining EDM processing --- --- --- test --- mold machining assembly - Flight mode -- Production test mode ---

2 / injection molding process: determine the yield of single-row --- --- confirm product quality in materials, structure, size --- --- packing production --- QC inspection.

Mold processing equipment: CNC lathe, EDM wire, EDM, wire cutting, drilling, grinding, general milling, high speed CNC computer gongs.

Injection Molding Equipment: Precision injection molding machine, (80T-320T) 16 sets, testers, 5 sets of crusher, blending machine 3 sets.

Processing capacity: mold design, mold making and plastic injection molding

Mold material: P20, 718,718 H, 2738,2316, S136, for you to choose Mold: 45 # pre-hard> 30 hrc

Cooling system: optimum design of the cycle of water, increase productivity, reduce your costs

Medium-term treatment: quenching and tempering to improve hardness.

Post-treatment: nitrogen (nitriding temperature is low, deformation is small, it is no longer the need for quenching high surface hardness (greater than HV850) and wear resistance).

Mould life: P20 normal use not less than 30 million times.

Mode of transport: in the mold must be installed before shipment clamping piece, logistics and transport.

After-sales service: 1 year mold warranty, free maintenance during warranty.

The company is located in Panyu District, Guangzhou City, Fu Long Industrial Zone, Shawan Town, mainly for customers to undertake precision plastic mold and plastic product development, design and manufacture, to hold the spark.Plastic product processing, such as: all kinds of apparatus plastic casing, shell lamps, plastic household items, plastic medical supplies, various chargers, automotive supplies, stationery, etc., we will warm customers one-stop service.

The factory has many years of production experience, a wealth of management and quality control staff, has a strong technical force, professional senior designer.

Jian-Cheng Zhang (Sales Representative) 13113960423

QQ: 893180301 / E-mail: gzs16868@